-

Posts

183 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Forums

Blogs

Gallery

Posts posted by tashikoma

-

-

yes i agree, easiest solution...

-

i was talking about the ALPS encoder . not the wheel rubbing or datawheel knob

in the WILBA design the datawheel encoder is the only soldered on the rear of the PCB:

http://www.midibox.org/dokuwiki/lib/exe/detail.php?id=wilba_mb_seq_construction_guide&media=wilba_mb_seq:spacer_locations.jpg

with ALPS stec 12 it's difficult to mount it on the rear , bending the lateral fixation legs in a reverse way for soldering is not ideal .

that why on my SEQ i have mounted all encoder on the front of the PCB.

but if you solder the encoder on a little piece of perfboard (with lateral fixation legs straight/centered not externally bended ) and drill holes near each lateral fixation legs on the perfboard (distance between each holes equal distance of the two hole for fixation leg on the PCB)

you could attach/fix the encoder on the rear of PCB with two screw and nuts...so you win some space for the datawheel knob shaft...

sorry for my english , i don't use the good words or syntax.... oops

-

what we would not do without our moms!

ALPS stec12 have no thread and nut ... not cool for the datawheel

don't think bending and soldering external legs will be solid if rear mouting....

mine is front "panel mount" ...

EDIT: perhaps soldering the encoder on a piece of perfboard and fixed it with 2 screws/nuts via legs holes on the CS board would do the job.... -

Yeah! Nice build!

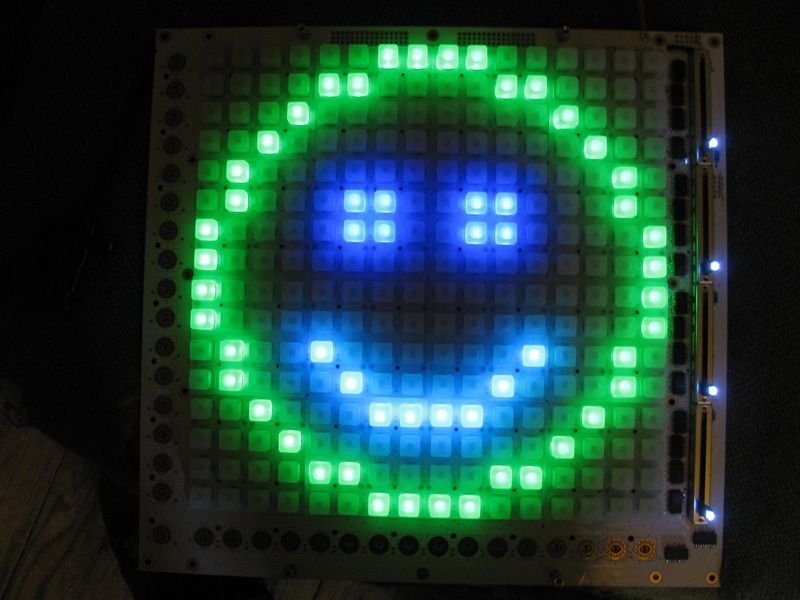

On 22/03/2016 at 0:28 PM, mongrol said:P.S. I have no idea what this thing does.

me too :D but so cool to have blinking lights machine !

is it the datawheel from adafruit? -

Yeah! Nice build!

On 22/03/2016 at 0:28 PM, mongrol said:P.S. I have no idea what this thing does.

me too :D but so cool to have blinking lights machine !

is it the datawheel from adafruit? -

Hello Karg

i use a pickit3 clone on windows....15 bucks ...perfect... works well .. i think it's the same unit than the original....same chinese manufacturer ...but not labelled microchip!

use with MPLAB X IDE or PIckit 3.01 programmer (free download on microchip) depend the .hex and device....

pickit 2 is better for some reasons... but pickit 3 compatible with latest device...

you have to use adapter or building it for each device in respect of datasheet.... and the "read me text" on "help" menu in software

Best -

10 hours ago, jjonas said:

GP buttons 15–16 behave strangely now,

No bug on my side with GP buttons on 4.091 beta.

but in MIXER maps does the hold SELECT button for activing LiveSend is implemented in EDIT Mode? -

Thanks jjonas, HW setup edited!

thanks too for your great manual....

-

Hi Thorsten,

On 13/3/2016 at 10:31 PM, TK. said:At least I added it to the wish list now, but I've to warn you: this will require some work, and might result into some unexpected issues which need to be solved. So, please don't expect a perfect implementation from the beginning.

When you have a lot of patterns to edit or make change, to speed the workflow , and sometimes i switch between patterns and forget to save...(i have to educate myself to remember saving

)

)

it's the habitude/pratice with other gear or daw, you edit all you save all at the end....

i don't want to waste your time ! if it's complicated forget it!

it's just an idea to discuss not a real request.On 13/3/2016 at 10:31 PM, TK. said:actually the entry of multiple loops only makes sense in conjunction with a BLM...

Added it to the wish list.

GREAT i really think it's a great feature.... (real request)

On 13/3/2016 at 10:31 PM, TK. said:need more details to understand the request

(it's for multiple midi outs config, like each different midi ports assigned to each tracks)

i use at 80% time the seq in edit mode. in this mode perhaps i'm wrong (i certainly missed something) but you can't assign a global mixer map (for the midi out ports and channels) for all patterns, in a same time?

you have to edit the midi outs and channels for each tracks of each patterns (could be very long).

in midi configuration there are the defaut port setting with available ports.... perhaps have the possibility to select a mixer map than a port on this page.

you stay with def. in event page for all tracks of all patterns and you select a mixer map int the def page that will act for all patterns...

if a track have a midi port assigned in event page it stay on this setting , but if def. is selectionned (event) and a mixer map selectionned in the def page (midi config) permit to have global (for all patterns) midi out config.

great for speed the workflow or for quick config change.

I hope to be understandable with my frenglich...

reEDIT:

request: the LIVE SEND function on MIXER MAPS (press n' hold SELECT) active in edit mode will do the job.

On 13/3/2016 at 10:31 PM, TK. said:By holding PASTE you can move the block

Great! that's it ! sorry for that! don't know the paste feature! perfect! also perhaps be cool to control that with the BLM...

On 13/3/2016 at 10:31 PM, TK. said:for which purpose?

after do a UNDO you could do a REDO! (not important )

it's just some ideas....or lack of knowledge, some are pertinent other are foolish!

thanks

Best -

i think too that the missing IC is another td62783apg but not important for debug....

if Braintu doesn't respond:

if all the DIN/DOUT board are ok

you can draw a schematic with wich switch DIN pin is wired to... same with led and DOUT.and editing the firmware with the correct DIN/DOUT map (there is one encoder it's like two switch)

how to compile a new firmware:http://www.midibox.org/dokuwiki/application_development

it's a simple project (i never build the clockbox but another projects about the same boards) and it's a midibox ....well documented ...good support... it's gonna live! -

Fortunately Andy speaks better French than I speak English!

Love this RGB leds .... nice illuminated pots!

Andy please stop making amazing projects , I'm gonna have the MBCV 2.01 on my TODO list.... if you continue i will have no time for the music!

-

1

1

-

-

Latigid is right , it's the test application loaded not the clockbox application!

after that:

There an empty socket for the big LED segment ... IC is missing ... i think without this IC the big LED won't work.there certainly a problem here ... that's why test app had been loaded.

what is the identity of regulator and the IC next the missing IC for the LED segment? -

magnifique!

-

Hi all

Some ideas:

- Autosave mode when pattern changing (cool for editing , not for live....) or a buffer for not loosing work....( more complicated for engine ressource cause the buffer must remember all pattern change)Save : normal /auto /buffer

-multiloop mode (each track have this own loop settings) could be cool with a BLM dedicated page! for jam with micro loops!

in loop page:

all tracks (static/view)

selected track (static/ view)

independant tracks (static / view)selection of loop-on per tracks but shorcut ALL+ loop-on will loop all tracks (with preselected value).

- MIDI FILTER for midi in (Song position Pointer/MMC/CC/Note)

- MIXER Map item at DEF. page port selection ( you could leave all your pattern in DEF port and a have one midi config for all your patterns.... nice if midi config change and quick way to config ) for EDIT mode.

- SYNC/QUANTIZE parameter per track (global track/pattern synchronisation in option page are not ideal for me, think need more brainstorming on this )

the problem is for the pattern change if you configure quick pattern change you can't use the sync to mesure function.... or i've don't understand something :D- BLOCK selection page for copying pattern blocks where you want in the pattern.... (could be cool with the BLM)

select with two GP button the block (interval between the two GP button) to copy and with SELECT+ GP button or the datawheel the point in the timeline to paste.

it's like the *press & hold* COPY function but with selectionnable paste in the timeline...

- REDO

i don't learn at 100% the seq possibilities so there's certainly some possibilities that i miss.....or ideas that already implemented! -

Hello midiboxers.

I use a lot Renoise ( i started trackers on AMIGA 500), with last Renoise 3.1 the midi clock is acceptable (not the previous version).

in my config of the moment :the Seq is in slave mode Renoise is master.

there is a function in renoise : block loop , it loop a block in the pattern, Renoise send MMC song position pointer to the seq so the seq loops too.great for rythmic not idéal for melodics

is it possible to have a MMC song position filter per seq track?

example: a track will be looped when renoise is looped and another will ignore the info.

could be great to remix drum track regardless a melodic track. -

hi mongrol

Mouser got the ALPS(without switch) and other brands... that could save shipping... -

et sa marche!

I love it , it's very very pleasant , quick note editing,very cool for drum tracks... keyboard with scale is great... youpi!

for the white sliders leds i go to 100k ... 68k was good too .10k is to bright but perfect for the red sliders origin leds

i don't stuff the verter buck/boost board... -

-

YEAH!!! AWESOME

nice job!

YOU ROCK! -

Yeah,

very nice sounds

my ears says THANKS!-

1

1

-

-

Hi Mongrol

yes completly possible!from the config file of seq:

# SR Pin Type

ENC_DATAWHEEL 6 2 DETENTED3# the speed value for the datawheel which is used when the "FAST" button is activated:

ENC_DATAWHEEL_FAST_SPEED 3# SR Pin Type

ENC_GP1 1 6 DETENTED3

ENC_GP2 1 4 DETENTED3

ENC_GP3 1 2 DETENTED3

ENC_GP4 1 0 DETENTED3

ENC_GP5 3 6 DETENTED3

ENC_GP6 3 4 DETENTED3

ENC_GP7 3 2 DETENTED3

ENC_GP8 3 0 DETENTED3

ENC_GP9 4 6 DETENTED3

ENC_GP10 4 4 DETENTED3

ENC_GP11 4 2 DETENTED3

ENC_GP12 4 0 DETENTED3

ENC_GP13 5 6 DETENTED3

ENC_GP14 5 4 DETENTED3

ENC_GP15 5 2 DETENTED3

ENC_GP16 5 0 DETENTED3As you see you could specify for each encoder the detented type , Bourns and ALPS are detented 3.

i don't like bourns (they loose step) but they fit PCB perfectly!

ALPS doesn't really fit!!! i have change Bourns to ALPS 2 weeks ago ... sorry i forgot take pictures... switch of datawheel assigned to LOOP ON/OFF... niceNeeds swap legs and surface mount , they have knurled short shaft! they needs more work and adjusting!

the ALPS with switch need to be surface mounted with 2mm space between the back of encoder and the pcb ( perhaps use 8mm spacer between PCB and frontpanel than 10mm spacer could help but this mean solder ICs directly and button caps will have extra 2mm on the front!)

Have no experience with SOUNDWELL or ALPHA but they fits!ALPS are available from REICHELT

-

Hi Thorsten

we agree we are talking MB SID V2 not the seq?

Thanks -

Hi workspace

never use extra flux but i gonna give a try... next order...Thanks for the tips

-

Hi all

the Wilba MB-6582 CS layout have push button encoder capability...

i don't find info on this!

is it implemented? how to activate it?

THX

Nico

PIC Programmer

in Parts Questions

Posted · Edited by tashikoma

Hi karg

my pinning yours is right

PICKIT_PIN1- 16F88_PIN4 a 10k resistor between PICKIT PIN 3 (so 16f88_pin5 ( vdd ))

PICKIT_PIN2 -16F88_PIN14 (Vcc) to connector for external power supply

PICKIT_PIN3-16F88_PIN5 ( vdd ) and to connector for external power supply

PICKIT_PIN4-16F88-PIN13

PICKIT_PIN5-16F88_PIN12

i power with external power supply in my remenber at 13.1v

cause the pickit can't provide more than 5v...so don't click power from tool...

i use Mplab X IDE or this (mirochip archive)

http://ww1.microchip.com/downloads/en/DeviceDoc/PICkit3%20Programmer%20Application%20v3.10.zip

but don't remember wich was .hex app buggy with wich pic.... (i had a problem one time with the pickit apps)

and you've got to switch with the correct mode with MPlab the pickit... also the pickit v3.1 apps don't want to close at home you've got to force it.

i haven't 16f88 in my stock to explain you the process!