-

Posts

1,234 -

Joined

-

Last visited

-

Days Won

28

Content Type

Profiles

Forums

Blogs

Gallery

Everything posted by Smithy

-

Just found a cheap source on AliExpress for the m3 threaded inserts for wood: https://a.aliexpress.com/_EwPghFj Be sure to select m3xm5x6mm

-

Also check out the wooden case that Technobreath designed. It's a simple case based on Sauraen's metal enclosure that he repurposed. I modified the 8 mounting holes so they would fit the wooden case. I'll be using 8 threaded inserts for m3 screws that I bought on eBay. You can find the pdf here: http://wiki.midibox.org/doku.php?id=mbqg_tb_case

-

Hey man. It's actually an FR4-Standard PCB. Non aluminium. But seems pretty robust anyway.

-

Hey phatline, I paid a total of $184.26 for the 5 sets of the front panel and rear panel PCBs. I'm negotiating a partial refund for the lack of paper and the 2 boards with marks on them. So that's $37 for 1x Front Panel and 1x Rear panel. I *think* Sauraen may have some green MBQG_FP PCBs that have not been sold, a few years ago he had some left at least. He is on travels at the moment so may not reply until he is home. The Genesis module PCBs are sold out on Modular Addict, so I'm not sure if any more are available. The MIDIbox Shop is closed down and Modular Addict (USA) is the new shop for PCBs. https://modularaddict.com/shop-by-brand/midibox-ucapps-de Best to check with Sauraen, another friend of mine is interested in buying a set of Sauraens PCBs and my panels also. I also need to try and prioritize the people who already have MBQG_FP PCBs. @Sauraen I could try and get some more people interested in buying PCBs by posting on relevant Synth DIY facebook groups and forums. When I complete the build guide I think more people would be enticed to build their own. Thanks for your time, Smithy.

-

Thanks dude! I filed a complaint with JLCPCB to get a refund due to absence of paper between the PCBs which I paid for and also a partial refund for the scuffed boards.

-

I have 4 Front Panels and 4 Rear Panels for sale. Please see this post:

-

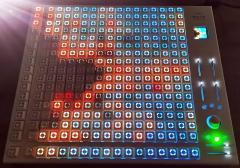

Update especially for people who have ordered Sauraen's Front Panel PCBs. TLDR: I have 4 Front Panels and 4 Rear Panels for MIDIbox Quad Genesis for sale. Life got in the way of both me and @ssp, and we lost contact for a few years! Thanks for your help dude, and if anyone would like acrylic panels laser cut you should contact him! The good news is that I ended up converting the Front Panels in .fpd format to PCB format using Kicad with lots of editing and learning. Here's how the Front Panels came out: I also designedRear Panels and this is how they turned out: Please note that the mounting holes for the Front Panel are designed to fit the DIY Wooden Enclosure that @technobreath designed for me: http://www.midibox.org/dokuwiki/doku.php?id=mbqg_tb_case You will need to use brass inserts that take 3mm bolts, drilled into the top of the case to be able to mount it. I will update the Build Guide I'm making with details on how to do this: The rear panel will require using a jigsaw or small saw to cut out the rectangle for the Rear Panel. I am really happy the way the precision of the Edge Cuts and how the silkscreen came out. The Front Panel PCBs fit Saureans green pcb underneath perfectly as you can see in the first image embedded Unfortunately JLCPCB did not put paper between the pcbs despite me paying for that option and 2 Front Panel PCBs had had minor scuffs: Nothing a Sharpie Pen couldn't fix though. If you are interested PM me and I can try and get a price for shipping it to your country. Just posting to see if there's any interest now.

-

Editing Wavetables (was: Ctrlr based editor for MBSID V2)

Smithy replied to Smithy's topic in MIDIbox SID

I am using a 12V 2A PSU that was used for an external harddrive and have Altitudes PSU mod installed on my MB-6582 with the fancy RECOM voltage regulators. I've had the issue with the original C64 PSU and power brick also so there may be a short or grounding issue. I think I could feel a tingle before when touching the fan's metal grill. I've procrastinated the repair in fear of making it worse but I will attempt to fix it someday! Thanks for the help with the Arp, I will try it out! I love how Insidious has the 4 clickable waveforms per step, as well as sync, ring mod etc.. And how it's much faster in general to recreate a SID tune. Not sure if it's possible to copy that UI without losing some features in CTRLr. If I have anymore ideas on a UI I will post them in the relevant CTRLr editor thread. Thanks Thorsten! -

Editing Wavetables (was: Ctrlr based editor for MBSID V2)

Smithy replied to Smithy's topic in MIDIbox SID

Central Park Loader.mp3 So the above is the result I get from MIDI track 1 (attached). Some unexpected high notes. Central Park Loader.mid Basically in wavetable 1, I'm copying straight from the video, Step 1 =0, Step 2 = +2 octaves, Step 3 = +1 Octave and repeated for the 12 steps. In Wavetable 2, I want the Triangle Waveform to play on each of the 12 steps. So in hexidecimal it should be a value of 01 on each step? I know that theres probably other ways of selecting the triangle wave but I'm trying to copy the video and understand how to put in the values. It could also be an issue with my MB-6582 causing unexpected behavior, I need to resolder joints as I get some noise at times. Any help would be appreciated, thanks. :) CentPark.syx -

Editing Wavetables (was: Ctrlr based editor for MBSID V2)

Smithy replied to Smithy's topic in MIDIbox SID

When I first started writing this post, the links opened fine from the User Manual on ucapps.de. Now I'm getting the page above. I can open the links from my post on the forum fine though? I figured out 2 settings which were messing up the wavetables, Instrument 1 in Multi Engine was set to Poly instead of Mono. And the "Wavetable Only" was not enabled in Rutgers Editor. Almost have the Central Park Arp sounding the same now except I get notes that are too high pitched. I'll post the results in my next post below. -

Editing Wavetables (was: Ctrlr based editor for MBSID V2)

Smithy replied to Smithy's topic in MIDIbox SID

The link to the 3 of these pages in the MIDIbox SID V2 User Manual Page are dead. MIDIbox SID V2 Parameter Chart MIDIbox SID V2 CC Implementation Chart MIDIbox SID V2 SysEx Implementation I'm trying out Rutghers Java Editor and can't figure out how to make an Arp with the Wavetables for the Last Ninja 2 Central Park Loader. While the wavetables are more advanced on the MIDIbox SID V2 I think they are harder to program than Insidious. These are just my initial thoughts. -

Editing Wavetables (was: Ctrlr based editor for MBSID V2)

Smithy replied to Smithy's topic in MIDIbox SID

I'll try playing with Rutgers editor in the coming weeks and will come up with some suggestions for the UI. Great to see you back! -

Editing Wavetables (was: Ctrlr based editor for MBSID V2)

Smithy replied to Smithy's topic in MIDIbox SID

Rutgers Java Editor has support for editing wavetable sequences, you need to have your MIDIbox SID connected via midi, both the output and input of your MIDI interface. You can download his editor here: http://www.ucapps.de/midibox_sid/v2_editor/MBSIDV2_Editor_v0_5.zip But yeah, it would be great to have a complete editor on Ctrlr. -

Amazing to see you active again Thorsten! Have you any plans or even the time to finish the Wavetable Editor for the Ctrlr panel? I would love to recreate the wavetables from classic c64 SID tunes. Fabio Marinelli is doing some great recreations using the Insidious VST on his youtube channel, and actively shares MIDI and project files for Cubase and FLStudio on his discord. If a clean UI could be made to simplify the process of sequencing of wavetables (something like the one in Indsidious) I would really be interested, i think Hawkeye is going through of a phase of exploring the classic wavetable sounds at the moment also! As always theres the older and free Reaktor Plugin for Insidious also: https://www.native-instruments.com/en/reaktor-community/reaktor-user-library/entry/show/8572/ Great to hear from you again, and hope all is well in Bavaria!

-

Soldering the Front Panel PCB From the Wiki: "Begin by soldering all the SMD shift registers and resistor packs. The pads aren't very big (if I had known, I would have made them bigger…), and I had a lot of issues with bad connections because a leg which looked soldered wasn't actually attached. If you have access to solder paste and a heat gun, use that. If not, apply solder to two corner pads on the board, place the chip on and melt those two legs into the solder to connect them. Adjust the position so that all the pins line up correctly. Then solder the rest of the legs, making sure to press down firmly with the iron on each leg just before applying the solder, in hopes that the leg will conduct heat to the copper and then when you apply the solder it will flow across the two." This is the most difficult part of the build and Sauraen was not messing around when warning about the small size of the pads. I tried drag soldering the SMT IC's and even though I used liquid flux most of the pads were not connected in each chip. Some chips had an entire side not connected as they were not aligned in the centre properly. I had to use a hot air gun to remove them from the pads and resolder. So you've 2 options, use the hot air and paste method or solder each leg individually and do not drag solder. Liquid flux will help the solder adhere to the pads. Ensure the chip is perfectly centred over the pads, otherwise the legs may not even come in contact with them. Another very important step is test for continuity between each pin, following the traces they lead to. Most of the pins between the shit register ICs and resistor networks are directly connected vertically as you can see in the picture above. For the other pins follow the traces which lead to pads and via testing holes and probe between them. Failure to do this may lead to less not lighting and encoders not working.

-

Drilling the mounting holes for the Front Panel

-

Connecting the diode from the Encoder Switch pin to J2 pin 6 solved the issue! There must be a short on the top side of the board under or near ENC4! Thanks so much for the help, and enjoy a beer on me! Must have been the longest troubleshooting effort ever! :)

-

My guess is theres a short under ENC4 somewhere but I'm finding it too difficult to desolder. At this stage I may just order 10 encoders from midiphy with a plate PCB.

-

Not exactly sure how useful this info is, but I de-soldered the positive leg of this Diode and the issue seems to go away, ENC4 turns normally without lighting up the SW20's LED.

-

The RN pins are definitely not touching, here's a photo showing how far the PCBs are apart from each other with the headers: Shorting J1 Pin 8 to GND even at that distance causes SW20 to illuminate. Any advice or images of traces to help me find the short on the Enc Plate PCB? On the underside of the PCB there is quite a few spots where the silkscreen has been marked and copper is showing. No traces seem to be exposed however.

-

Still no short between ENC4 pins and J2 Pin 6. With the ENC Plate PCB installed when I short J1 pin 8 to GND the SW20 LED lights up and I get the following in debug, it includes touching the pin and releasing from it: [1036341.011] MBNG_MATRIX_NotifyToggle(1, 28, 0) [1036341.011] MBNG_DIN_NotifyToggle(2028, 0) [1036341.012] [EVENT] id=BUTTON:2028 hw_id=BUTTON:2028 bank=0 fwd_id=LED:2031 type=NoteOn value=0 label= [1036341.013] MBNG_DOUT_NotifyReceivedValue(2031, 127) [1036341.014] MBNG_MATRIX_DOUT_NotifyReceivedValue(2, 31, 127) [1036341.015] MBNG_MATRIX_NotifyToggle(1, 44, 0) [1036341.016] MBNG_DIN_NotifyToggle(2044, 0) [1036341.016] No event assigned to BUTTON hw_id=2044 [1036341.020] MBNG_MATRIX_NotifyToggle(1, 60, 0) [1036341.021] MBNG_DIN_NotifyToggle(2060, 0) [1036341.021] No event assigned to BUTTON hw_id=2060 [1036341.024] MBNG_MATRIX_NotifyToggle(1, 12, 0) [1036341.024] MBNG_DIN_NotifyToggle(2012, 0) [1036341.025] [EVENT] id=BUTTON:2012 hw_id=BUTTON:2012 bank=0 fwd_id=LED:2016 type=NoteOn value=0 label= [1036341.026] MBNG_DOUT_NotifyReceivedValue(2016, 127) [1036341.027] MBNG_MATRIX_DOUT_NotifyReceivedValue(2, 16, 127) [1036341.029] MBNG_MATRIX_NotifyToggle(1, 36, 0) [1036341.030] MBNG_DIN_NotifyToggle(2036, 0) [1036341.030] No event assigned to BUTTON hw_id=2036 [1036341.033] MBNG_MATRIX_NotifyToggle(1, 52, 0) [1036341.034] MBNG_DIN_NotifyToggle(2052, 0) [1036341.034] No event assigned to BUTTON hw_id=2052 [1036341.038] MBNG_MATRIX_NotifyToggle(1, 4, 0) [1036341.038] MBNG_DIN_NotifyToggle(2004, 0) [1036341.039] [EVENT] id=BUTTON:2004 hw_id=BUTTON:2004 bank=0 fwd_id=LED:2015 type=NoteOn value=0 label= [1036341.040] MBNG_DOUT_NotifyReceivedValue(2015, 127) [1036341.041] MBNG_MATRIX_DOUT_NotifyReceivedValue(2, 15, 127) [1036341.042] MBNG_MATRIX_NotifyToggle(1, 20, 0) [1036341.042] MBNG_DIN_NotifyToggle(2020, 0) [1036341.043] [EVENT] id=BUTTON:2020 hw_id=BUTTON:2020 bank=0 fwd_id=LED:2024 type=NoteOn value=0 label= [1036341.044] MBNG_DOUT_NotifyReceivedValue(2024, 127) [1036341.045] MBNG_MATRIX_DOUT_NotifyReceivedValue(2, 24, 127) [1036341.060] MBNG_MATRIX_NotifyToggle(1, 20, 1) [1036341.060] MBNG_DIN_NotifyToggle(2020, 1) [1036341.062] [EVENT] id=BUTTON:2020 hw_id=BUTTON:2020 bank=0 fwd_id=LED:2024 type=NoteOn value=127 label= [1036341.062] MBNG_DOUT_NotifyReceivedValue(2024, 0) [1036341.063] MBNG_MATRIX_DOUT_NotifyReceivedValue(2, 24, 0) [1036341.070] MBNG_MATRIX_NotifyToggle(1, 20, 0) [1036341.070] MBNG_DIN_NotifyToggle(2020, 0) [1036341.071] [EVENT] id=BUTTON:2020 hw_id=BUTTON:2020 bank=0 fwd_id=LED:2024 type=NoteOn value=0 label= [1036341.072] MBNG_DOUT_NotifyReceivedValue(2024, 127) [1036341.073] MBNG_MATRIX_DOUT_NotifyReceivedValue(2, 24, 127) [1036341.080] MBNG_MATRIX_NotifyToggle(1, 12, 1) [1036341.080] MBNG_DIN_NotifyToggle(2012, 1) [1036341.082] [EVENT] id=BUTTON:2012 hw_id=BUTTON:2012 bank=0 fwd_id=LED:2016 type=NoteOn value=127 label= [1036341.082] MBNG_DOUT_NotifyReceivedValue(2016, 0) [1036341.083] MBNG_MATRIX_DOUT_NotifyReceivedValue(2, 16, 0) [1036341.088] MBNG_MATRIX_NotifyToggle(1, 12, 0) [1036341.088] MBNG_DIN_NotifyToggle(2012, 0) [1036341.089] [EVENT] id=BUTTON:2012 hw_id=BUTTON:2012 bank=0 fwd_id=LED:2016 type=NoteOn value=0 label= [1036341.090] MBNG_DOUT_NotifyReceivedValue(2016, 127) [1036341.091] MBNG_MATRIX_DOUT_NotifyReceivedValue(2, 16, 127) [1036341.186] MBNG_MATRIX_NotifyToggle(1, 44, 1) [1036341.186] MBNG_DIN_NotifyToggle(2044, 1) [1036341.186] No event assigned to BUTTON hw_id=2044 [1036341.192] MBNG_MATRIX_NotifyToggle(1, 52, 1) [1036341.193] MBNG_DIN_NotifyToggle(2052, 1) [1036341.193] No event assigned to BUTTON hw_id=2052 [1036341.197] MBNG_MATRIX_NotifyToggle(1, 4, 1) [1036341.197] MBNG_DIN_NotifyToggle(2004, 1) [1036341.198] [EVENT] id=BUTTON:2004 hw_id=BUTTON:2004 bank=0 fwd_id=LED:2015 type=NoteOn value=127 label= [1036341.199] MBNG_DOUT_NotifyReceivedValue(2015, 0) [1036341.200] MBNG_MATRIX_DOUT_NotifyReceivedValue(2, 15, 0) [1036341.201] MBNG_MATRIX_NotifyToggle(1, 20, 1) [1036341.201] MBNG_DIN_NotifyToggle(2020, 1) [1036341.203] [EVENT] id=BUTTON:2020 hw_id=BUTTON:2020 bank=0 fwd_id=LED:2024 type=NoteOn value=127 label= [1036341.203] MBNG_DOUT_NotifyReceivedValue(2024, 0) [1036341.204] MBNG_MATRIX_DOUT_NotifyReceivedValue(2, 24, 0) [1036341.205] MBNG_MATRIX_NotifyToggle(1, 36, 1) [1036341.206] MBNG_DIN_NotifyToggle(2036, 1) [1036341.206] No event assigned to BUTTON hw_id=2036 [1036341.210] MBNG_MATRIX_NotifyToggle(1, 60, 1) [1036341.211] MBNG_DIN_NotifyToggle(2060, 1) [1036341.211] No event assigned to BUTTON hw_id=2060 [1036341.215] MBNG_MATRIX_NotifyToggle(1, 12, 1) [1036341.215] MBNG_DIN_NotifyToggle(2012, 1) [1036341.217] [EVENT] id=BUTTON:2012 hw_id=BUTTON:2012 bank=0 fwd_id=LED:2016 type=NoteOn value=127 label= [1036341.217] MBNG_DOUT_NotifyReceivedValue(2016, 0) [1036341.218] MBNG_MATRIX_DOUT_NotifyReceivedValue(2, 16, 0) [1036341.219] MBNG_MATRIX_NotifyToggle(1, 28, 1) [1036341.219] MBNG_DIN_NotifyToggle(2028, 1) [1036341.221] [EVENT] id=BUTTON:2028 hw_id=BUTTON:2028 bank=0 fwd_id=LED:2031 type=NoteOn value=127 label= [1036341.221] MBNG_DOUT_NotifyReceivedValue(2031, 0) [1036341.222] MBNG_MATRIX_DOUT_NotifyReceivedValue(2, 31, 0) This does not happen without the Enc plate PCB installed / connected. I also tried doing it with the arduino headers installed to separate the PCBs further like in the photo below, and I do get the events and SW20's LED lighting up still. So this should rule out a short between components touching on both boards. Shorting J1 Pin 9 to GND has no effect. Would I be right in thinking there's a short somewhere on the ENC Plate PCB?

-

So i tested for shorts between all encoder legs of ENSW4 and the pins of J2 - nothing. Disconnected the plate PCB and shorted pins 9 and then 10 of J1 to GND. Nothing comes up on Debug. (I even removed the comment # character from the DIN line in seq_r.ngc and tried a second time just in case.

-

I set it up in RH mode (from left to right: Core -> LE MEC -> LE MEC RH -> JA PCB ) and loaded up seq_r and the issue remained. I commented out the DIN MATRIX line in seq_r.ngc for the RH PCB and this is the result of turning ENCSW4 clockwise one detent with set debug on: [ 657.687] MBNG_DIN_NotifyToggle(36, 0) [ 657.688] No event assigned to BUTTON hw_id=36 [ 657.702] MBNG_ENC_NotifyChange(12, 1) [ 657.703] [EVENT] id=ENC:12 hw_id=ENC:12 bank=0 fwd_id=DISABLED:0 type=CC value=0 label= [ 657.708] MBNG_DIN_NotifyToggle(36, 1) [ 657.709] No event assigned to BUTTON hw_id=36 I noticed SW20 did not light up this time when turning. The Mattias LEDs Common Cathode are still desoldered, so not sure if these would light up in this column with DIN commented out. I presume I was not meant to comment out DOUT_MATRIX? Thanks!

-