-

Posts

12 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

AndyJott's Achievements

MIDIbox Newbie (1/4)

0

Reputation

-

-

The cutouts will just be made cleanly .... no need to worry for that

-

hmmm. then I think will start with an analog patchbay for now. Thanks for your help !

-

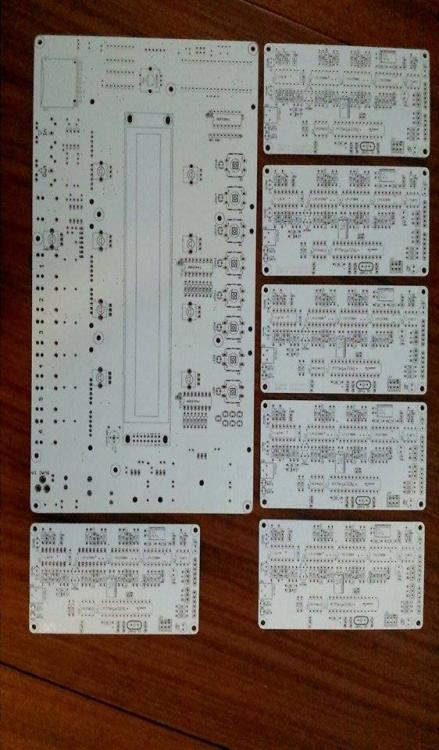

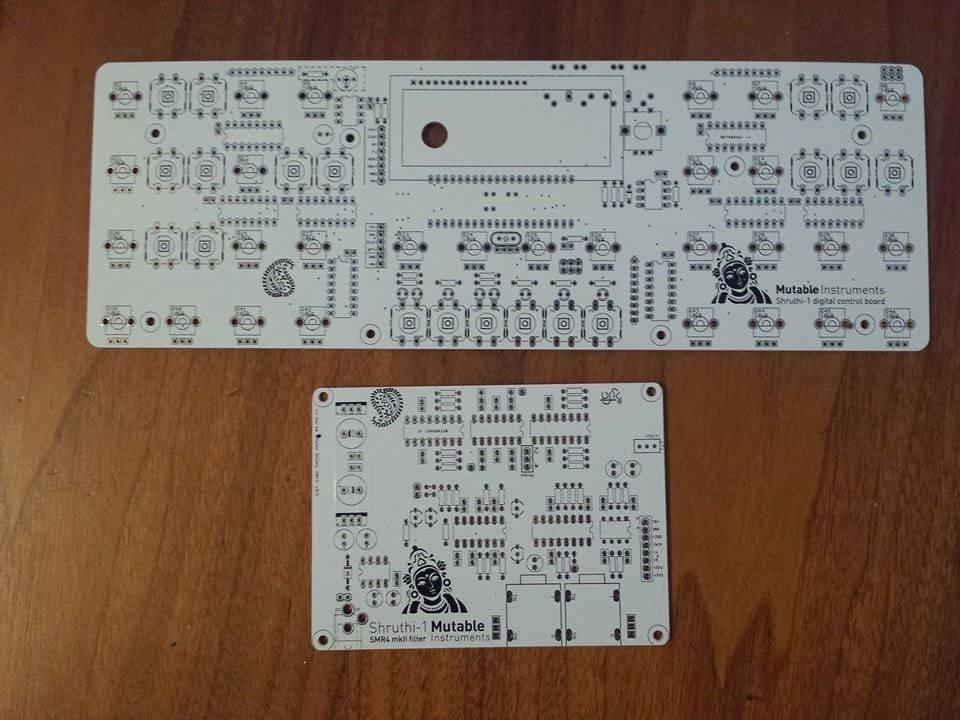

Hello, I don't exactly know if its ok here to offer non-Midibox stuff. If this is so just delete this post. On the other hand there are plenty of non-Midibox offers here, so I hope its ok. Actually I have 3 pcb sets for the Mutable Instruments Ambika to offer (1 Motherboard with 6 SMR4 voicecards each). Link to the toy: http://mutable-instruments.net/ambika In a short for anybody who doesn't know what an so called 'Ambika' is ... it's an polyphonic Synthesizer :) If you are interested in more details just go to the page I mentioned and have a look. The price for 1 set is at 110€ + shipping from Germany.

-

I want to switch audio signals in my home studio. I am searching a solution where I can handle more than 16 ins/outs while still staying flexible all the time. Most affordable audio interfaces have a maximum of 16 input channels. Usually this are 8 out-of-the-box and 8 additional ones per ADAT extension or s.th. like that. Today I would be satisfied with 16 ins, because I have not so much external gear that the number of 16 need inputs gets exceeded. But for sure in the future there will be the one or other more gear which need to fit into my setup. With a 32x32 matrix switch I would stay very flexible to a) virtually connect only the devices I actually need in a project to the given 16 ins, b) share channels if it suits the situation, c) not have the need to (dis)connect cables and d) save the virtual wiring configuration for my projects. You told about 2*16x16 .... it's actually 4*16x16 as the needed matrix ic's count will exponentially rise to the channels you want. It shouldn't matter if there are mono or stereo signals as long as the routing gets configured as needed. For example I have a Mutable Instruments Shruti which actually is mono and on the other hand a Virus TI with 6 independant channels. I'd feel better if I can build that device on my own, not only because I think it gets a bit cheaper. As I said I already own 4 AD75019. Opamps arent that expensive and sockets are cheap to buy in china (aliexpress.com) . On the other hand ... selfmade gear is just cooler if it doesn't lack power in comparison to 'professional' gear. Sadly I still don't know if this project 'makes sense', because I have no doubt if the audio quality will suffer from the signal chain. But I can't imagine that it actually would do that much, because it isn't more than simply an input buffer and a mixer circuit with the matrix switch ic in the middle of them. If anybody could answer this question I'd finish the details of the schematics and create the board layouts.

-

k, just found this thread .... have to read through it :) http://midibox.org/forums/topic/10490-diy-audio-patchbay-with-digital-routinghow-hard

-

Hello, my vision is to create a 32x32 digitally controllable audio matrix. I already created a very basic functional concept based on the AD75019. But the IC in fact doesn't matter for now as it's still exchangable in my plans. Because I already own 4 AD75019 i've choosen them to create my first basic schematic. As I am only a software engineer with some basic knowledge in electronics I wanted you to have a look over this and tell me if its complete bullshit or perhaps ( I hope so ) a good base to start. As I read at http://www.midibox.org/dokuwiki/doku.php?id=midibox_audiomatrix I think the biggest problems which can occur is the mighty crosstalk problem (where the MT8816 should fit better than the AD75019) and possible gain problems when routing 1:n or n:1 . I read that even n:1 would make bigger problems than 1:n . If I understood it right, when making 1:n, it would solve the problems if I just add some buffer opamps after the matrix outputs. When I wanted n:1 I need something like a mixer style schematic running through the matrix IC. This would mean I have to add some resistors before the input of the matrix ic. In common to the 1:n option I also have to add an buffer opamp at the outputs of the matrix IC. To be able to chain multiple matrix ICs I also added some buffers before the inputs to be able to distribute the incoming signals to multiple ICs. Additional to that I added resistors and a final output buffer stage to merge the outputs of multiple matrix ICs. I don't know what would happen when making n:m connections. Should this be prohibited or is it possible without side effects ? Is this a reasonable idea or isn't it good to chain opamps ? Simplyfied it's nothng more than 2 opamp mixer units chained through the matrix ics. Will the audio quality suffer from this ? To keep it scalable I'd split boards into 3 types (without the controlling board and other stuff around).... 'input (distribution) stage', 'chainable matrix boards', 'output stage'. I hope you were able to understand my idea in this :) Best regards, Andreas 32x32 audio matrix 01.pdf

-

My experience with the pcb manufacturer 3PCB.com

AndyJott replied to AndyJott's topic in Miscellaneous

@ Phatline: Up to 22€ you don't have to pay tax. From 22 to 125€ you only have to pay the German 19%. Above 125€ you'll get charged some extra tax from the customs duty. @Altitude. I I have a redeem code for new customers too. So you can save extra 5 dollars if you are interested. http://www.pcbway.com/setinvite.aspx?inviteid=7680 -

My experience with the pcb manufacturer 3PCB.com

AndyJott replied to AndyJott's topic in Miscellaneous

OK there is the MBSID, but I meant a more up to date styled synth. I think the STM32 Core could be suitable for this. Perhaps I'll start something on my own some day when I have more time left to spend. -

My experience with the pcb manufacturer 3PCB.com

AndyJott replied to AndyJott's topic in Miscellaneous

I didn't want to feel you get spammed. Sorry for that. Perhaps some people are interested in it, for sure others won't be. I am reading the forum a long time yet. I am still waiting for some synthesizer stuff here instead of only controllers. -

My experience with the pcb manufacturer 3PCB.com

AndyJott replied to AndyJott's topic in Miscellaneous

-

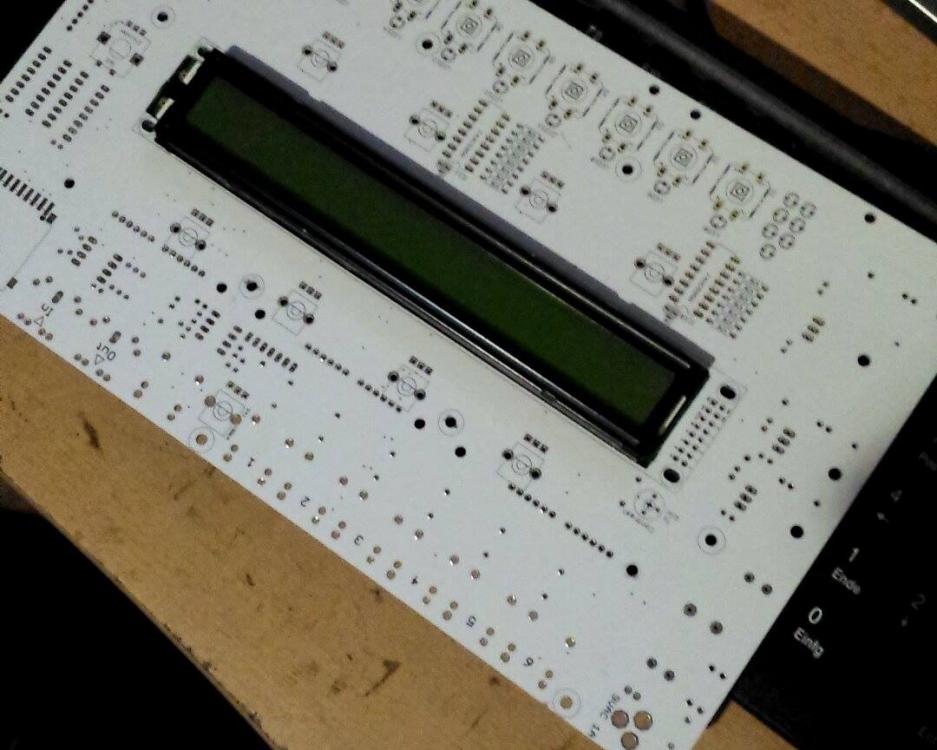

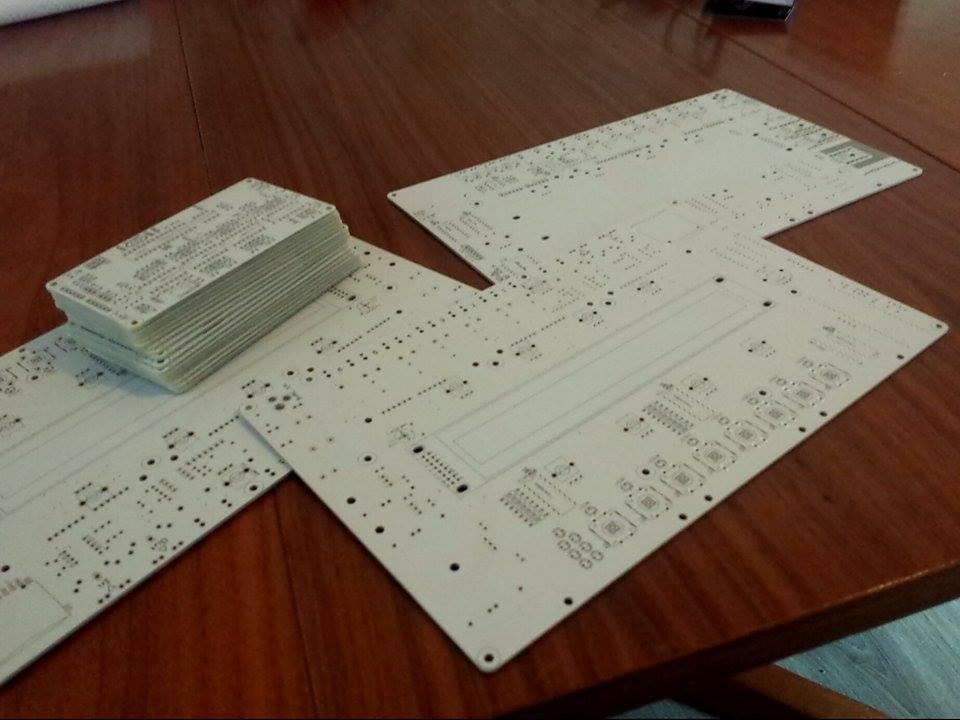

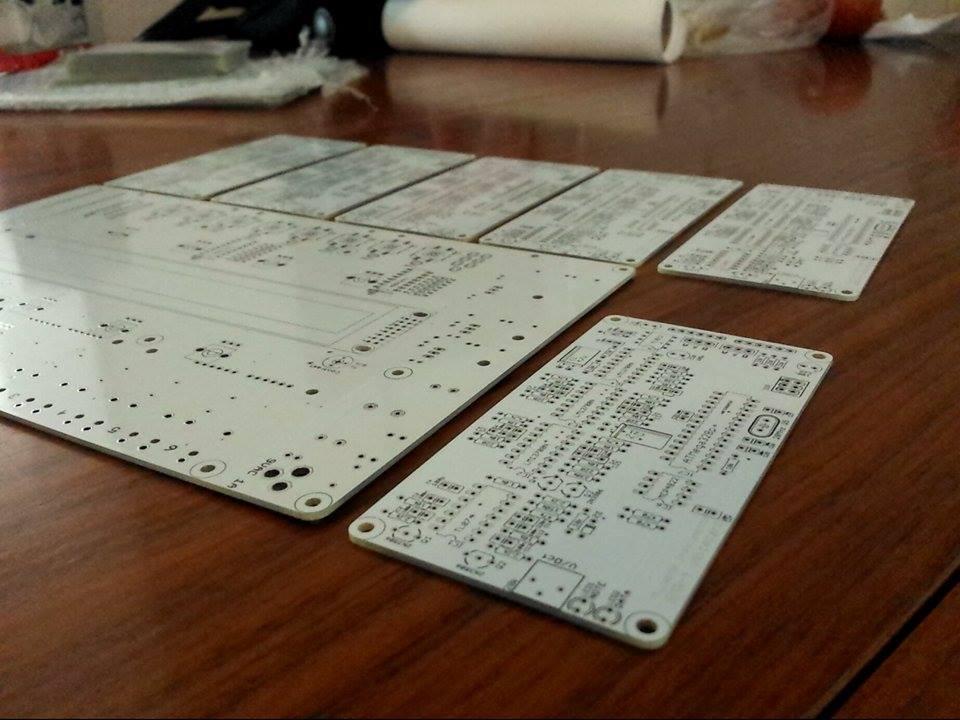

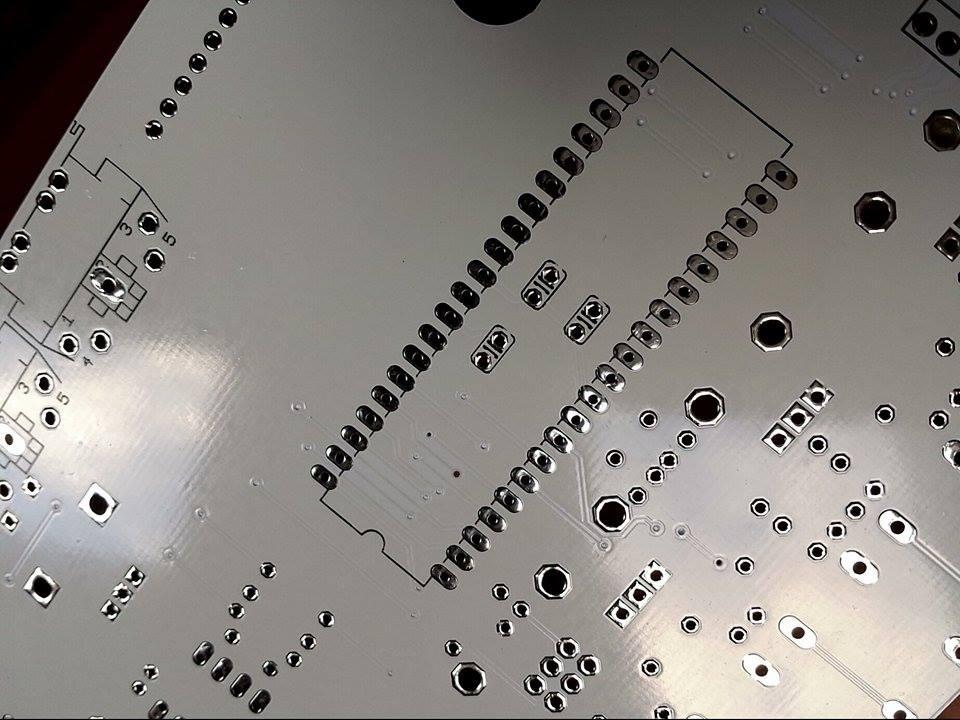

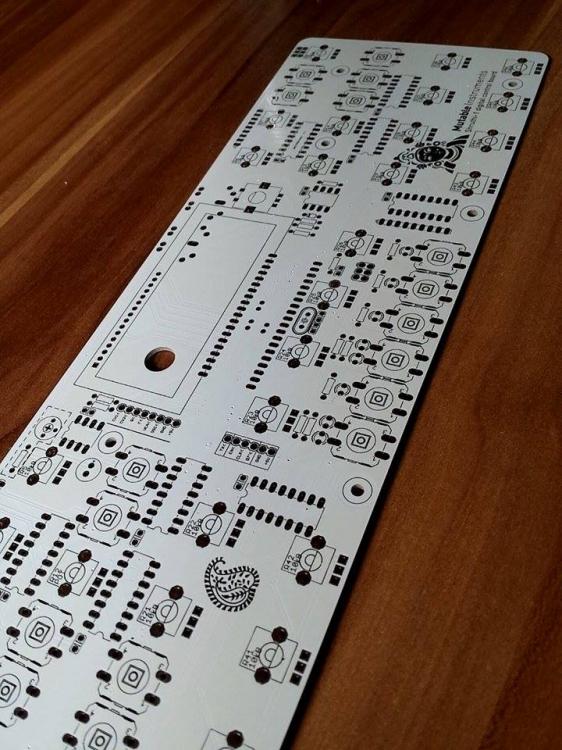

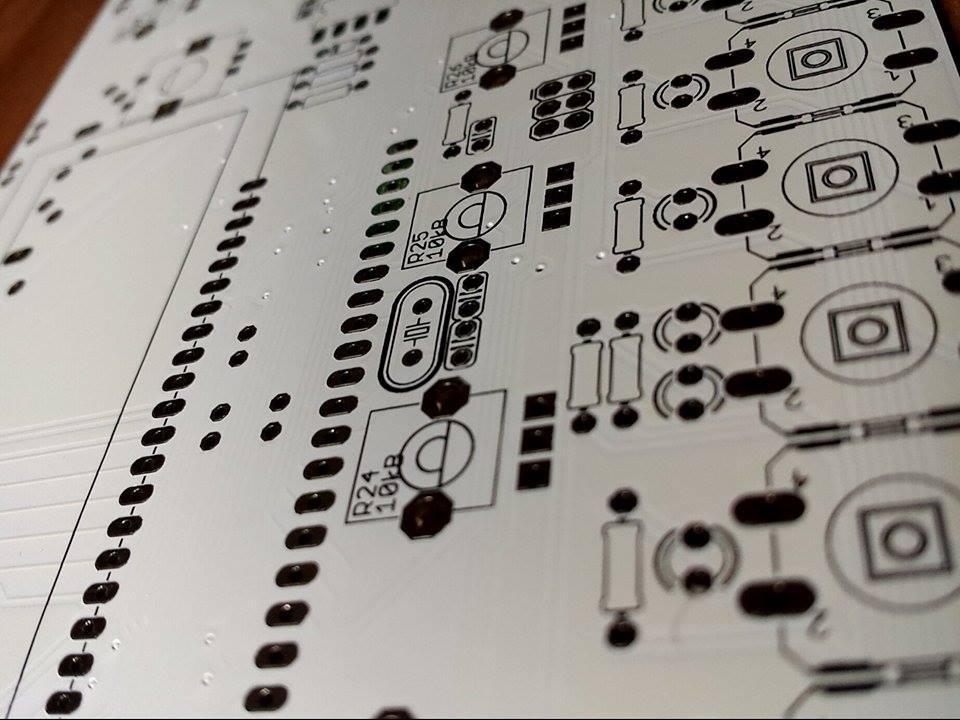

Hello people, so my name Andy and I there I am. I like this site and hopefully will find some interesting things for my upcoming projects. But before I start new projects I have to finish my actual ones. But I try to keep getting inspired by sites like this one. My actual project is the Mutable Instruments Shruti. I am building 2 for me and 1 for a friend. What I want to tell to you is a recommondation for a pcb manufacturer called 3pcb.com . I know lots of you are interested in building cheap pcbs and because not everybody has the possibility to create his own pcb I'll show one of the, for my oppinion, best pcb manufacturers you can get. 3PCB is located in China which causes really very low prices, but with a high quality production. PCBs can get manufactured with a minimal amount of 5 units up to everything you want. "Oh, but I don't want 5 units" you'll perhaps say. But let me tell you that probably these 5 units cost less or not much more than the production of a single prototype board if you buy elsewhere. Let me tell you about the possibilities: Layers: ?1 Layer ?2 Layers ?4 Layers ?6 Layers Thickness: ?0.4 ?0.6 ?0.8 ?1.0 ?1.2 ?1.6 ?2.0 ?2.4 (mm) Solder Mask: ?Green ?Red ?Yellow ?Blue ?White ?Black Silkscreen: ?White ?Black Surface Finish: ?HASL with lead ?HASL lead free ?Immersion gold Finished Copper: ?1 oz Cu ?2 oz Cu I paid only 83 dollars plus the shipping costs for five board sets with a size of 385x100mm and a thickness of 1.6mm each. They would even be more cheap if I didn't want white boards with a black a silkscreen on it. And the quality is really great. There are no sharp edges or a bad silkscreen. Everything is very professional like it should be. So, but something more related to the people working there........ I am not the most professional person when it's on to build up pcbs and I dodn't know how to order them correctly. That means I didn't know anything about what files I have to supply to a pcb manufacturer. All I knew is that there is something calles Gerber format which should be delivered. At 3PCB you have to upload your gerber files in a zip archive when making the invoice. After that they'll check the files and give a feedback to you if everything is correct and producable. I opened up Eagle and tried to export the ready .brd file which I have from the Mutable Instruments site to the gerber format. After opening the export page I felt very helpless. I didn't know which layer I should place into that file which gets written there. I did wrong in every aspect. I exported all layers to a single gerber file and uploaded this to 3PCB ( I hear you laughing :) ) . The next day I received a response from 3PCB where they told me, that I uploaded wrong files and they described me moer detailed what files they need. They told me about various files for the upper and lower copper, silkscreen, drills and holes and all that stuff. The text was written by hand and it was no kiond of copy and paste styles response what I got what I felt very happy about. I knew I got some real support from a real human. Suddenly I exported again some unusable crap. It has been several files, but somehow some details were wrong again. After I uploaded the faulty files and got a reply again after jut 24 hours. No joke. In that mail I was told more clearly about the differences of the kind of files I have to supply. The best thing was that they sent me a document where everything was described really clearly. The supplied a link to me, where I was able to download something like a 'preset' for exporting which I had to load in the Eagle export screen. Then I saw my (big) mistake. Now there were much more tabs and in each there has been exact specific setting for each of the files they needed. All I had to do now was to give the files names. After exporting the files all corresponding layers were grouped correctly and in the correct file format. I never were able to get this done without their really great help. So after the correct files has been delivered to 3PCB I was able to see the exactly production stage my pcbs were from the initial cuttings of the pcbs over to etching to silkscreening to drilling to electrical test and finally to the delivery to sending them out to me in real time down to minutes. When I talk about delivery ... you can coose between Hong Kong Post Airmail and DHL express. I've chosen DHL and after they sent out the PCBs they arrived in under one week. The hole process from the start didn't last longer than 2 weeks (including the correction I had to do on the files I supplied). If you are not satisfied you are able to open a complaint, but to this I can't tell you anything, because I had not to do it. I am really satisfied with their work. So my tip for you, if you want to let produce some pcbs, go and try 3PCB. I just have the n ext project where I need to get some PCBs made. ( It's the Ambika of Mutable instruments ). The PCBs I need have a size of 325 x 280 millimeters. I'll order again the minimum amount of 5 pieces which costs only 190 dollars plus the shipping costs. In reality this are 5*7 PCBS, because its not one big pcb but one mainboard and 6 so called voicecards. Another nice thing is, that you dont need to order every single board. Instead of that you are able to put everything in a single layout and they cut the various pcbs for you. Isn't that great ? :D So last but not least I am very sure you ask why I tell all this to you so very detailed. The answer is that beside I don't want to let you not know about this great manufacturer is, that 3PCB gives redeem coupons if you share your expirience to other people. This will make your next order quite more cheaper than it is. They'll redeem from 30-100 dollars for it. Regards, Andy