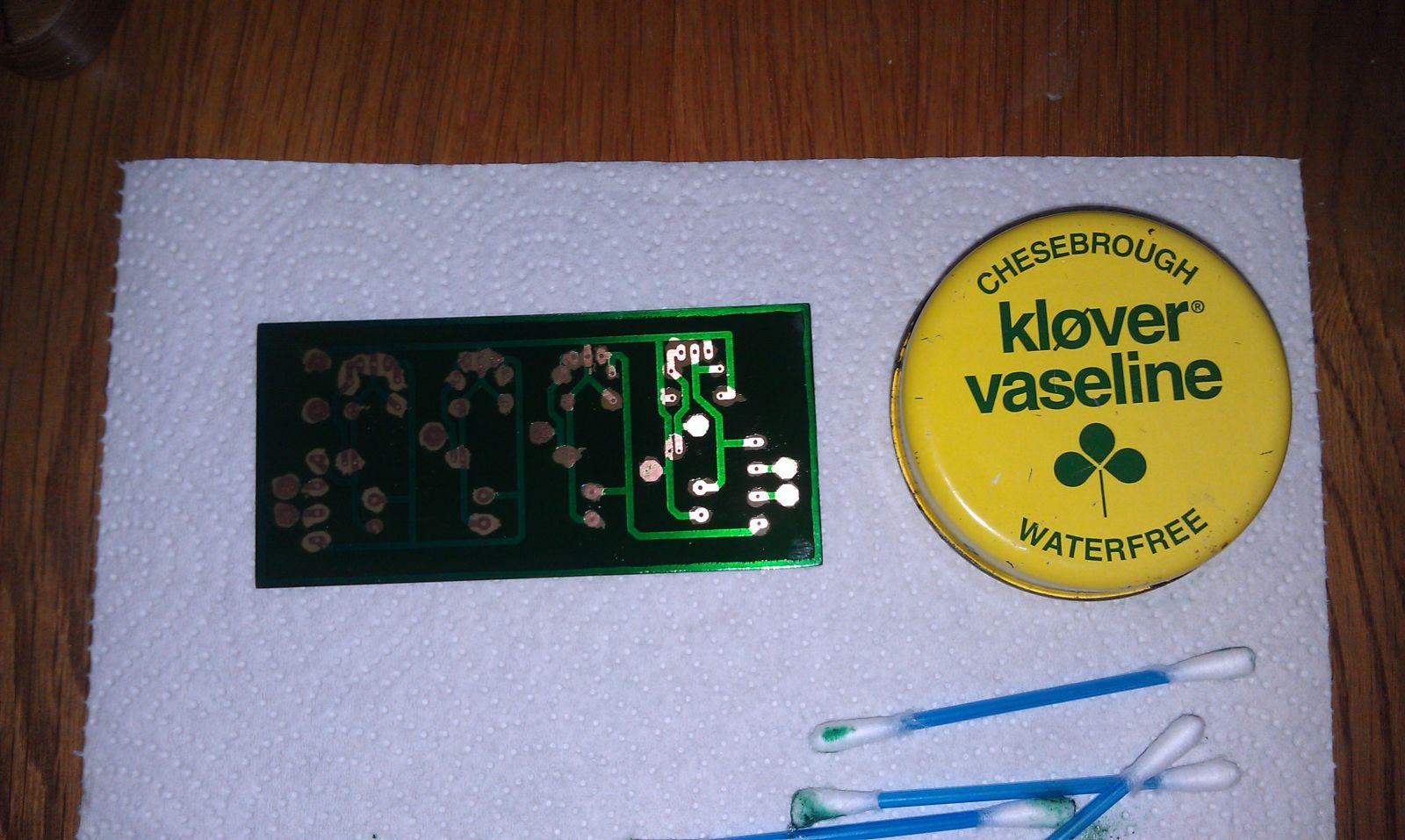

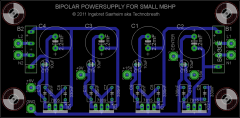

PSU board and vaseline

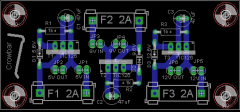

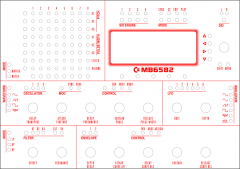

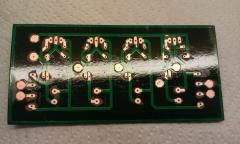

PSU board together with the good stuff.<br /><br />When I had etched the board I cut the tip of a q-tip diagonally, so it was sharp and pointy. Then I use it to apply the vaseline to all the pads. A rather blacksmith kinda way to do things, but certainly worked well as you can see. It took great care with the q-tip to not spill vaseline all over the place.<br /><br />When the pads were masked with vaseline, I carefully sprayed the soldermask on. Let it dry, then let it dry even more under my wife's hairdryer - then I carefully tried to remove the vaseline to see if I could remove it without harming the soldermask (I wasn't quite sure it was all set yet). But it was, and I just used the q-tips to remove the vaseline, and then washed it with soap and water to remove the rest of that good stuff.<br /><br />The results you see here. A little unprecise with the masking of the pads (too much spill) but I am really pleasd with the results.<br /><br />The soldermask is one of those "solderthrough" spray-on soldermasks, but smash told me it was much work cleaning the iron during soldering through the mask, so... that is why I did it like this. No tip cleaning / tip-ruining :).<br /><br />Now it only lacks holes. Smallest drillbit I god is 1mm. Too big for the smaller components, and it can be difficult to fill all the smaller pads, and not just half the hole, because it is too big, but with a bit of practice and care it goes just fine. 1mm is about the smallest drillbit the chuck on my drill will accept too, so I gotta make it work ;).

Recommended Comments

Please sign in to comment

You will be able to leave a comment after signing in

Sign In Now