-

Posts

322 -

Joined

-

Last visited

-

Days Won

10

Content Type

Profiles

Forums

Blogs

Gallery

Posts posted by julianf

-

-

The LXR is surprising nice. Although i built the electronics ages ago, ive only just started using it, now that its in a box.

Im surprised by the range of sound, from smooth TR style hits, right through to FM ringing, to reduced sample rate crunches. And i have not even got into messing with the sample side of it yet. I think its a nice piece of work, (who's designer is still on the ball with the firmware).

I reckon the minimum i can probably ask the wood place for is 5-off. The do custom furniture all the time, but, although all it is is a simple box, i think the price will just be too high on a single unit. I guess if there is even another couple of people interested, ill buy 5-off and keep 2 for stock.

In hindsight, this thread probably should be in group buys? If a mod thinks similar, could it be moved?

-

I recently made a case for my own LXR drum machine (sonic potions) and two things have come to mind -

a) people often ask me if i sell the 17" desktop enclosure for the panels i cut (i dont), and

b) a case like the one below is simple enough to be adapted very easily

Here's some photos of the case i made for the LXR -

(screw holes in that last shot should have screws in them!)Here are my comments about the case -The wood on the sides is reclaimed oak, from a timber place close to me, that does fancy furniture made from reclaimed timbers (i live in an area where 200 year old beams are common place).

(screw holes in that last shot should have screws in them!)Here are my comments about the case -The wood on the sides is reclaimed oak, from a timber place close to me, that does fancy furniture made from reclaimed timbers (i live in an area where 200 year old beams are common place).

I went for the square, machine drum, style look, rather than the sloped panel. I made a mock-up with a sloped panel first, but i did not think it looked as good. For such a small machine, im not sure that there is much ergonomic advantage, and i like that 'slab' look more!

The panels are gloss black anodised aluminium, with silver engraving. The key caps fit the switches perfectly, and don't fall off : ) The allen bolts are A2 stainless, and will stay shiny.

The logo is vectorised from this website. Maybe i should have added the LXR also, but i like the clean look and its contrast against the ancient oak.Im not set up for woodwork here - whilst i can make the odd thing, i dont have the tooling for multiple copies, but, if there was interest, the place that i got the wood from would make up the cases at a price, and i could cut the top and rear panels.

So this is just a feeler. The costing would (i hope obviously) be multiples of a lazer cut plastic case - hand made with ancient hardwoods will never be comparable with plastics, but im guessing there may be some interest in quality?

So...?

note: i was not sure if this should be in bulk orders or the seq section?

-

I see your issue now.

Im not sure how possible its going to be with wood.

With metal -

Imagine a U section, but with the tops of the U lipped over, so you get this kind of shape -

[_]

...but all out of one bit of metal. Say 0.8mm mild steel.

That's almost a diy bending job. You could then 'block' the ends with chunks of wood.

-

Can you take the whole lot up from the base of the case?

So, from bottom to top, it would be -

bolt head on wooden base, with thread pointing up toward the inside of the case

wooden base

threaded spacers, with the bolt from the bottom screwed into them - these would need to be long enough to take another bolt from the other side also

then the pcb

then a non-threaded spacer

then the top panel

then a nice looking bolt, that goes down, through the panel, through the non-threadeed spacer, through the pcb, and into the same threadded spacer as the bolt from the base comes into

Assuming your case edges were nice and rigid, and the case itself was not very weighty, would this be sufficient?

-

Brian,

What issues are you having, exactly?

The hole spacing on the panel is according to Wilba's original files, and will be the same as any other panel cut with the same files - are you using his pcb layout, or another?

Julian

-

Does anybody know what happened to Julian? He suddenly didn't respond to PMs anymore. His last sign in was over a month ago. In my case it was right after he told me that my panel was finished and ready for shipment. We where about to decide for the shipping method when he didn't respond to my answer. Does anybody have any information?All good, we're back in contact after the abrupt Christmas hols.

The above transaction was concluded ages ago, but, just to be clear to the casual reader - the delay was *prior* to me taking any payment. For me, that's quite an important detail, which could be missed! : )

Of course, any delay is tedious, but delays after payment is made are, in my mind, another issue entirely.

I should also give thanks to Highcooley for his purchase, even in spite of the quiet period! : )

-

Im really not trying to pick holes in your sale, but havn't the front panels been recessed and engraved on the same side?

-

Ill post on some other forums when i get arround to it, but i may as well start somwhere!

Ive cut a number of custom panels for people here. Ive wanted an online shop thing for some time, but i never get arround to sorting it out.

I would like someone who knows what theyre doing to put me together a woocommerce shop, with automated stock etc. in exchange for metal work.

BUT -

For better or worse, i like the look of my existing website. I know i can get an off-the-shelf paypal cart, but i dont want this - i want to keep the look of what i have, but have it converted to wordpress with woocommerce. I do *not* want somthig that just looks like every other corporate wordpress site.

I figure someone here may have the smarts on this, and be in need of somthing i have the skills with - trade skills, rather than money? : )

If youre keen, drop me a pm, would you?

Thank you,

Julian

-

he's talking about the 4L not the full seqV4

Yes, sorry - my mistake!

For what its worth, i purchased a sheet metal former a while back, but i need to rebuild (yep, pour concrete and stuff) the workshop before i get arround to that kind of caper : /

-

Might i ask who the EU distributor is?

-

There were group buys for the aluminium desktop case, and, somwhere in the posts, the spec for the case is listed - you could go to the manufacturer for a 1-off, or, possibly, even see if there was interest in another uk group buy?

As for the top panel, im probably your cheapest metal option?

-

The case frame, base, and ends are from one of the group-buys that ran here. It was supplied by www.heidenreich.de

As i say, the one above was from a group buy, but im sure they can be purchased individually also.

The top and rear plates were cut here. They are cut from Wilba's files, but with some alterations, most notably, adjustments so as the panels fit the case tighter / firmer. The panels in the photo are also 1.5mm, which means that they fit into the case rails themselves, rather than needing (expensive) profiling. The entire set (front and rear) then works out cheaper than just the original top panel, and also creates a stronger build.

-

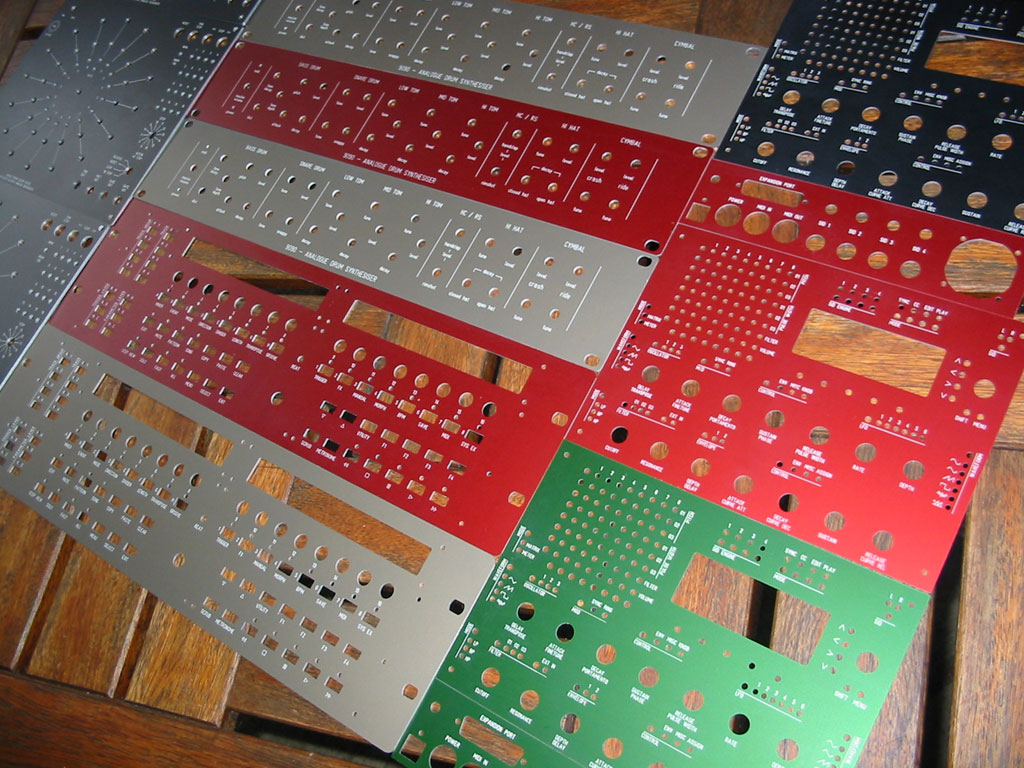

Some pretty photos of the desktop case -

Files have been edited to give better fit etc.

The power switch on the rear has also been changed to an SCI part, which people tell me is easier to get hold of? (SCI is a large brand, and should be available world-wide)

One extra output port is added to the rear panel.

-

I have a bunch of panels to make next week, and, due to the way the runs are arranged, i have some irritating gaps.

Normally i just fill these with 'stock' panels, but i thought id try something different and see what becomes of it? : )

So...

Gaps available -

3-off 19" x 1u rack panel size

3-off 5u x 1u MOTM / Oakley size

All 3.0mm natural anodised.

Terms -

You can have whatever you want on these (within my capabilities : )

I will charge exactly 50% of whatever FPD quotes you on the panel (for EU customers, this will be the inc vat, ex delivery, price)

Your (final) files must be with me by Monday morning (13th) and you must be good to make payment at around the same time (assuming your works are assigned a place)

Notes -

In the case of higher demand (than expected!) I'm afraid ill go for the higher value submissions. This isn't entirely selfish - if i can save someone a whole load of cash, against saving someone else only a bit, it seems 'just' so give the most benefit.

Postage from me is always at cost price only. I ship world wide. I take bank payments in GBP or Euro (both free), cards with Google Checkout (standard surcharges) and Paypal (but *only* if its marked as a 'personal' payment with all fees pre-paid)

Lead time will be about a week.

Due to life getting in the way, i have not been overly active on the forums recently, but, if you want reminding of what i get up to, the following link should show you -

http://www.thebeast.co.uk/cnc/index.html

Thank you,

Julian

The Beast UK Ltd

www.thebeast.co.uk

-

Only one week till the sale ends!

-

Hmm... Im pretty sure that i dont have it any more, however, i keep meening to go through things here, and find out exactly what i do and dont have!

Im pretty sure i have a cheap (reject) 19" panel, but, if you have the desktop case, that's no good to you.

I think standard price for the desktop panels is GBP 80 for the top, and GBP 35 for the rear, but, of course, if i do still have the panel in the photos, you would be very welcome to it.

Ill have a look through things, and post again!

Julian

-

10% off all mb6582 (standard cut only) panels paid for between 15th April to 30th April 2013.

My MB6582 panel sets are usually GBP 80 each (which is already a huge saving on the other company : ) but, between the dates above, you will be able to get a further 10% off, giving a saving of about GBP 40 / Euro 50 on the alternatives!

What's included -

Any standard cut mb6582 panel (ie no custom designs)

Any stocked metal colour

Any stocked single infill colour

What's excluded -

Any panels *paid for* outside of this time frame (15th April to 30th April 2013)

Any other panels / custom panels

Postal charges still apply (always at cost only anyway!)

Packing - its free anyhow, so i cant give you 10%-off nothing!

Transaction charges (if applicable)

Payment methods -

UK Cheque (FREE)

BACS in GBP (FREE)

BACS in Euro (FREE)

Google Checkout (standard charges apply)

Paypal "Personal / Gift" with charges pre-paid (this is the *only* way that I'm happy to accept Paypal)

-

Price drop - GBP 60 (ex shipping etc)

If it does not sell, ill be tempted to put the price up again!

-

Im amazed that noone has bitten my arm off for this one! Its a graded panel, sure, but two small marks by the window, and ive got it listed for aprox 1/2 what a 3mm panel would cost.

But, hey...

Ill knock another fiver off, and see what happens. GBP 55 (ex shipping etc)

-

Somone has said to me that they are finding it difficult finding the power jack / switch (?) that TK used for his build.

As i have not yet milled the panel, i can change the cut-outs for these.

Is the part TK used (i do not know what it is) hard to find? Would the panel be better with a standard 12.6mm circular cut-out for any number of the barrel connectors (most companies seem to make them for a 12.6mm cut out)

My 'local' place sells these - http://www.rapidonline.com/Cables-Connectors/DC-Power-socket-for-panel-cut-out-12-6mm-63543

...but i have checked that 'branded' options are available with the same cut-out hole. The 12.6mm dimension seems common enough.

Im thinking a cut-out for a small round rocker switch too, for example -

http://www.rapidonline.com/Electronic-Components/SPST-Snap-in-rocker-switch-71446

SCI parts are available all over, so i do not think there would be issues three.

If TKs choice of parts are available, then i have no desire to change the holes at all - it is less work for me to keep them as-is, however, it is horrible not being able to find some obscure part for a build, so i always try to cut for the most available options.

Can anyone give me feedback on this?

Thank you,

Julian

-

Will you offer matching display protectors/case or what they are called in English? (e.g. made from Acryl)

Probably not this time. But there is thought behind this -

The panel you see in the photo is 1.5mm thick. Same thickness as the mb6582 units (dont worry - its plenty thick enough for strength!)

With the 1.5mm metal the edge of the cut that you see around the screen is so much less (well exactly 1/2!) so (with the mb6582 units) i have suggested to people that they cut a screen themselves, with a hacksaw (cheap option!) as the whole part can then affix to the rear of the panel, and none of the edges of the acrylic of it would be visible.

If you profile an acrylic part to 'slot' into the hole in the metal, the edges of the acrylic are right where you are looking. So they need to be clean. But, if the whole part is under the metal, the edges are out of sight - so it becomes a DIY part once again.

Having a large 'step' of 3.0mm on a thicker panel, and then an acrylic screen below may look a bit 'odd' but with the thinner metal, i think that the DIY option explained above reduces both the complication and expense for the end user.

note -

of course, there is nothing to stop anyone getting an acrylic part profiled to match if they want to - indeed, they can try the option above first, and then, if they dont like it, go to the trouble and expense of buying a profiled part (but i doubt that many would! : )

note #2 -

the 1.5 metal is availible in many more colours / finishes than 3.0 too. as above, the 1.5 is what i use for the mb5682 units, so any colour / finish that you have seen those in is possible for the mbseq unit. my personal unit (if i ever have time to build it!) will have a matt red panel, in a black case, with black panel hardware : )

-

Some will have noticed that ive been about these parts a little more often just recently : )

The reason for the radio silence was a drawn out relocation, and then quite a while recently battling with technical issues.

Anyhow, i posted these photos in another thread -

This was only a test panel, as i needed to check the dimensions of the panel. The datasheet for the desktop case is a fair way out on some of the dimensions, hence the need to take real-world 'actual' measurements, and then cut the test plate.

So, the top is now confirmed. I have just engraved a test for the rear panel, and will cut that over the weekend.

This is the set that i have cut -

The rear panel is basically TKs file, but with the typeface altered to match in with the top panel, and the addition of the Sync port between the last midi and the BLM.

I want to get the rear finished before talking pricing, but its looking like the whole set (top and rear) will come in cheaper than buying just the top from FP..

Anyhow, i guess this is pre-warning. They are on their way (eventually) so, i guess, time to start thinking about it if youre after one : )

-

thank you,

i have your mail - i will engage my eyes and brain on them later in the day : )

thanks again,

julian

-

As per i needed to cut a test panel for the mbseq desktop enclosures to check all the measurements.

Because i did not actually think the job would work, i used a bit of scrap metal, that had been heavily engraved on one side.

The test panel actually came out perfect, and is way too good to put back into the scrap.

Photos below -

So, what's wrong with this panel?

a) there are no pcb mounting holes cut. youre on your own here, with JB weld, or whatever epoxy resin brand you have local to you : )

b) the panel was heavily engraved on the rear side. i was doing testing with it, and there were some deep cuts, two of which punchered the panel on the left hand side just below the LCD window (two little dots in the last photo)

c) this isnt actually a real issue, but its somthing ill adjust on later panels - ill cut the panels 3/4 of a mm longer in the future. there's a tiny (well, 0.75mm) bit of slack in the case, which is identical to the slack in the other sections, but, hey, now that i know about it, ill adjust the cutting files to get rid of it : )

The engraving and holes are flawless. So, visually, its the two dots by the right hand LCD window. Again, the rear of the panel is a mess, so dont expect anything pretty there!

I think Wilba's 3mm design works out at about GBP 120 ish from the big engraving companies. How about this one at half that? GBP 60, ex shipping / transaction costs (where applicable)

Usual terms -

Postage at cost.

Packing free.

Payment by bank transfer in GBP or Euro, or...

By google checkout (usual processing fees apply) or...

By paypal, but *only* if marked as a gift, with fees pre-paid (basically i hate paypal, and have never taken it up until now, but, if you want to use it, that's the only way ill do it : )

Insurance / tracking is optional (at buyers risk) for items paid for by bank / paypal gift

Insurance not optional for card payments by other means.

ps. im sure its obvious, but we're talking just the engraved panel, not the whole case : )

SEQ4 Heidenreich Case Bulk 2014 / 2015

in Bulk Orders

Posted · Edited by julianf

My 1-off price on front panels for the Heidenreich is GBP 80 (which comes to 100 euro)

My 1-off price for the rear panels is GBP 35

Im very pleased to see someone organizing a group buy for the cases - indeed, i may be a customer for a few myself, as people ask me about them often, but both in my own interests, and those of potential purchasers of panels, i have to comment as above.

I hope my post does not offend. I would wish any group buy luck, but, again, the group buy pricing on the panels is *way* above what i charge for even a single unit.