-

Posts

1,236 -

Joined

-

Last visited

-

Days Won

28

Content Type

Profiles

Forums

Blogs

Gallery

Posts posted by Smithy

-

-

On 5/14/2021 at 6:22 AM, latigid on said:

I just hope that it wasn't 3x BAT54 on top of each transistor ;-)

This approach works best I found when the solder has burned through its flux. If it's too hard, you could consider a fleck of copper tape or a strand of wire.

Haha not 3 on top of each other no!

I'm short 2 components from the BOM, they may have not been finalized when I orderered back in the stone age as Peter would say! ;)

I'm short the 4816P-1-103LF Resistor network for RN5 on the LE MEC RH PCB so I presume its needed?

Also i'm missing 929700-01-36-RK - the longer Pin headers. I believe these need to be about 8mm long from the top of the plastic to the top of the Pin itself (when standing upright).

I think I've found some equivalents on RS, could you double check Andy if you dont mind?https://ie.rs-online.com/web/p/pcb-headers/6812310/

I'm going by dimension "B" in the datasheet:

https://docs.rs-online.com/36e1/0900766b8135fed6.pdf -

Thanks for the prompt replies!

I must be insane (I guess we all know that right? ;) ) As I have went ahead and soldered 3 bat54 diodes on top of the BC818s.

It's not easy getting the solder to reach the pins of the diodes but I'm getting there!

5 more to go.

-

Something has me stumped with the build guide video part @ 58 mins

Peter is soldering BAT54 diodes to the LeMEC pcb.

I don't have any markings for BAT54 diodes on my LeMEC pcb. My PCB version is 1.0.

I only have markings for BAT54 diodes on LeMEC RH PCB of which I have version 1.3_R.

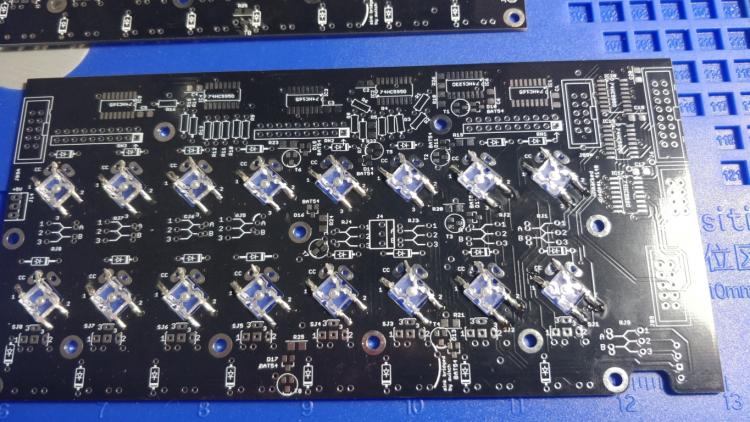

Here is the LeMEC pcb I have with the backside showing:

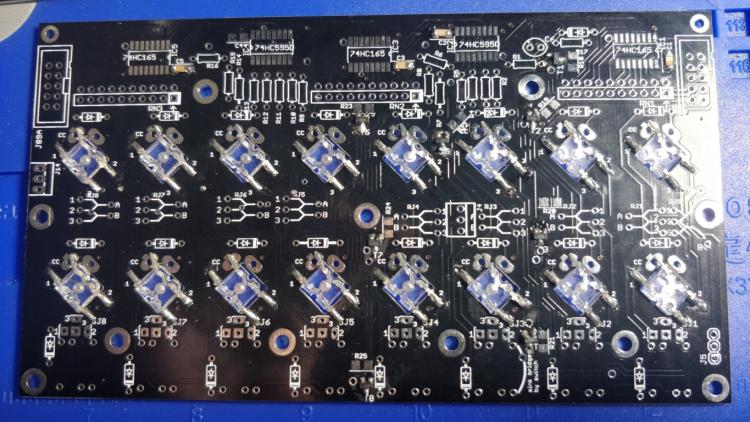

And heres the backside of the LeMEC RH PCB

Is it okay to ignore the bat54 diodes on the LeMEC board and proceed?

Thanks.

-

28 minutes ago, latigid on said:

No need to replace that pad, pin 1 does not connect to anything.

Best,

AndyCan't believe I lucked out!

I usually use a temp of 350 degrees C for soldering including drag soldering.

After this I would recommend using a temp closer to 300 degrees for SMT parts!

Thanks a lot for your help Andy.

The encoder, switches and LEDs are working beautifully.

-

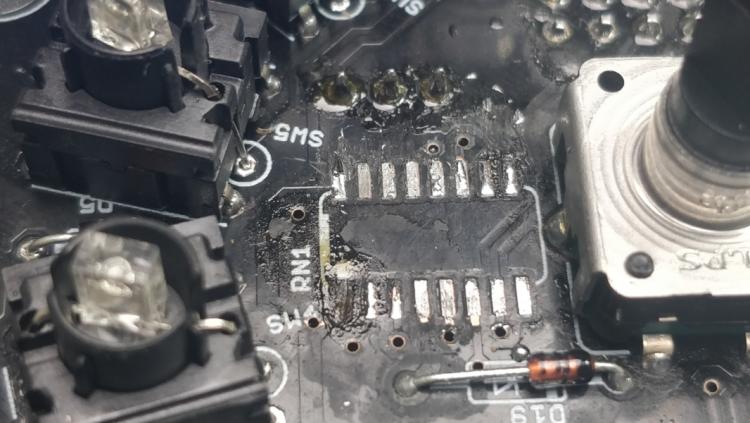

So I removed the chip fine but ended up lifting the pad for pin 1 when trying to solder the correct 10k resistor network.

I had problems getting the solder to take to that pad when aligning the chip - I should have used the chisel tip instead of the bevel to apply solder to the corner pads first.I usually only use the bevel tip for drag soldering.

I applied some flux also and that must have been enough to lift the pad.

Is there anywhere I can solder a bridge between pin 1 and a pad it connects to?

-

Sort of answered my own question there.

If anyone has any advice on how to desolder the chip, what temperature to use, should I use flux or solder paste, it would be great.

I also have kapton tape for nearby components. -

On 12/18/2018 at 10:02 PM, rbv2 said:

it is labeled 4816P LF1-103 C1745 ..

this is the wrong one right?

edit:

it definetly is the wrong part. .which leads me to the next wrong part on the LE MEC RH PCB.. :D

thank you so much for you help!!!

So I've been getting erratic behavior with the LEDs on the switches of the JA PCB.

I wonder if i made the same mistake soldering the wrong type resistor network?

The markings on the IC at RN1 are 4816P LF1-103 C1809

instead of 4816P-T02-103LF.

I blame myself for not checking the BOM on midiphy and solely relying on the video!

Thankfully i have a hot air station, flux and solder paste so should be able to remedy this issue. -

-

54 minutes ago, ssp said:

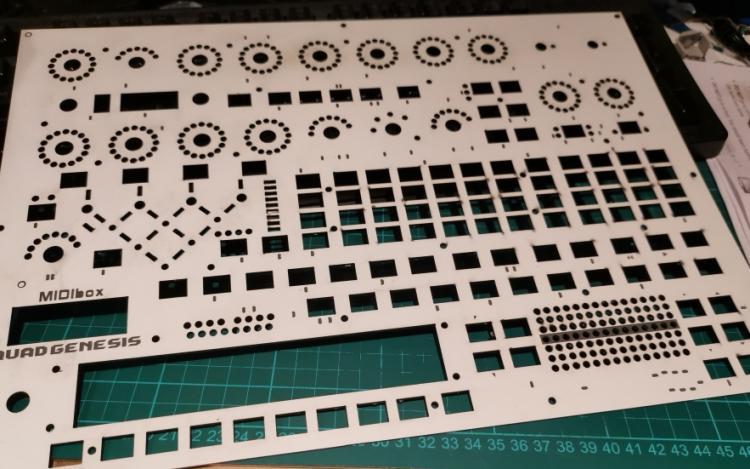

Thanks SSP. The cutting came out great! Well done! Hell I'd even label it manually myself if needs be. Let me know if you have any suggestions. Thanks a million, Smithy.

-

On 2/7/2021 at 2:56 PM, ssp said:

Hey Smithy, i have an Atacam laser system in work i use, do you have this as a dxf file? i can do a panel test when i call in next week. I can do a cut on some 2, 3 or 4mm laser acrylic and see how it comes out. I can set the text to scan engrave and the rest to cut, probably take a couple of mins.

Hey SSP, thanks for reaching out and apologies for the late reply!

I would definitely be interested in paying you for a laser cut acrylic front panel.

The one slight catch is I need the engraved text to be legible with a high contrast to the rest of the panel.

Is it possible that you could use Cast Acrylic at work for this?

Or a two tone acrylic e.g. black acrylic with a white core?

I am trying to avoid infilling the engraved acrylic with paint manually.

As you can see, the original acrylic case for the midiphy loopA for example is difficult to read even in well lit conditions:

http://midibox.org/forums/topic/20833-loopa-v2-introduction-features-support-thread/The cast acrylic would be well illuminated with the high amount of LEDs in the panel also.

Which country are you based in by the way?

Please find the dxf file attached and the original fpd file it was exported from.

Thanks for your time,

Smithy.mbqg_fp_modledrings Updated Case Holes.dxf mbqg_fp_modledrings Updated Case Holes.fpd

-

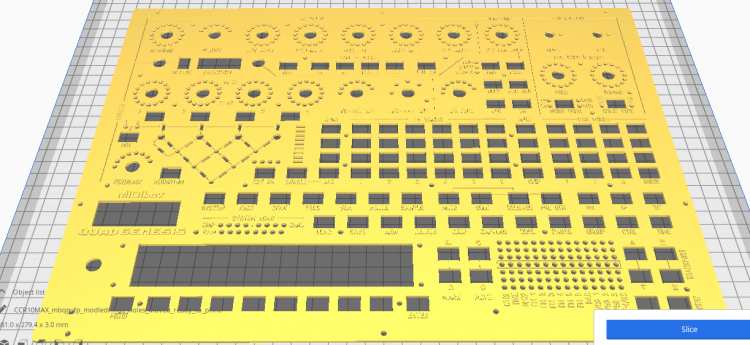

[3D Printable Front Panel File for use by Wiki]

mbqg_fp_modledrings_Holes_Moved_ready_to_print.zip

Attached is an STL file of the front panel with raised lettering for use with 3D Printing

To produce a bi-coloured panel with a different colour for the lettering please follow this easy guide:This file is provided as a lower cost method for producing a 3D printed front panel as opposed the cost of having an alluminium panel milled by Schaeffer which costs 410 euro in the EU excluding shipping.

However, it may be better to use an SVG file to have acrylic laser cut, which will be cheaper to order online and have more accurate cuts and engravings.

I have an SVG file ready and working with the Formular.de ordering system, but it is not currently compatible with Ponokos ordering system so I have emailed them.I will update the thread if I make any progress with Ponoko.

Here's a preview of the 3D Printable STL file:-

1

1

-

-

On 2/7/2017 at 5:21 AM, Sauraen said:

[Uploaded front panel files for use by wiki]

Here are some additional 3D Models / STL files for the Buttons and Light pipes converted to the metric system for 2mm Panels:

mbqg_fp_buttons converted to mm for 2mm panel.stl

mbqg_fp_ledpipes converted to mm for 2mm panel.stl

And these files are for 3mm panels with the appropriate mesh extruded / lengthened.

-

1

1

-

-

Here's a tip for anyone who wants an easy way of having raised lettering on their 3D prints with a different colour to the case itself.

Print the case with lettering with the same colour filament you want the raised lettering to have.

Paint or (spray paint is probably best) the entire case in the colour you want the case to be.

Then simply sand the lettering with sand paper and the original filament colour will come through.I saw this method posted in a facebook Flight Sim group where a user 3D printed his own Boeing 737 panels:

-

Here's a tip for anyone who wants an easy way of having raised lettering on their 3D prints with a different colour to the case itself.

Print the case with lettering with the same colour filament you want the raised lettering to have.

Paint or (spray paint is probably best) the entire case in the colour you want the case to be.

Then simply sand the lettering with sand paper and the original filament colour will come through.I saw this method posted in a facebook Flight Sim group where a user 3D printed his own Boeing 737 panels:

-

2

2

-

-

User BEBDigital Audio kindly uploaded files for a 3D Printed case 6 days ago, just in case you guys are subscribed to this thread:

-

Excellent work! Very clean looking.

-

Congratulations on your hard work everyone involved! Nice to see a MIDIbox device finally get the recognition it deserves!

I just wanted to update the thread and say that I had the intermittent booting issue since I built my LoopA and since installing those 2 resistors Andy suggested, it has been flawless!

Such a fun little device to get ideas down quickly while remaining inspired and in the moment! One of the most important things for my workflow!

-

2

2

-

-

Had a lot of fun of making this Live Cover of Anthony Rothers classic electro banger - Little Computer People.Used the midiphy LoopA to sequence and live loop this one.All the gear used is mentioned at the end of the video.I'm still recovering from surgery on my neck so the vocoder could be stronger. Enjoy.

-

On 8/16/2020 at 4:23 AM, Smithy said:

Edit: On second thought I had problems pushing one or 2 knobs as the heatshrink gets in the way.

Best to use sellotape like peter said or some thinner material.

I tr ied Peters method of securing the knobs to the shafts of the encoders with Sellotape but I found the tape simply would not stick well to the encoder shafts and sometimes fell down to the bottom causing noise when turning the knobs.So I came up with a more permanent or secure method.I used blue heathrink as you can see in the first pic that was as close to the diameter of the top half or the D shape of the shaft and shrunk them with my hot air station at about 200 degrees taking care not to heat up the encoders too much.Then I slipped on the knobs with some force and they secured quite nicely.Only con really is that more force is needed to get them off again but i'd rather that than having loose knobs getting lost!Hope this is of use to people.On 8/16/2020 at 4:23 AM, Smithy said:I tried Peters method of securing the knobs to the shafts of the encoders with Sellotape but I found the tape simply would not stick well to the encoder shafts and sometimes fell down to the bottom causing noise when turning the knobs.So I came up with a more permanent or secure method.I used blue heathrink as you can see in the first pic that was as close to the diameter of the top half or the D shape of the shaft and shrunk them with my hot air station at about 200 degrees taking care not to heat up the encoders too much.Then I slipped on the knobs with some force and they secured quite nicely.Only con really is that more force is needed to get them off again but i'd rather that than having loose knobs getting lost!Hope this is of use to people.

Updated my post above as the heatshrink was getting in the way of pushing down 1 or 2 knobs. I might try Kapton tape instead now. -

On 17/08/2020 at 1:52 AM, Narwhal said:

I’ve seen those board sets at ModularAddict. But it seems that their website is down for a bit, so you may need to just wait for them to come back.

I wouldn't count on them coming back anytime soon just fyi. Logan who was running the shop for John has left to pursue his own business - Low-Gain Electronics.

John was too busy to manage it himself so unless he comes back or finds a replacement to run the shop people will be waiting.

Also worth noting that John has not been active on the forum since April 2018.

-

Beautiful work!

-

1

1

-

-

Edit: On second thought I had problems pushing one or 2 knobs as the heatshrink gets in the way.

Best to use sellotape like peter said or some thinner material.

I tr ied Peters method of securing the knobs to the shafts of the encoders with Sellotape but I found the tape simply would not stick well to the encoder shafts and sometimes fell down to the bottom causing noise when turning the knobs.So I came up with a more permanent or secure method.I used blue heathrink as you can see in the first pic that was as close to the diameter of the top half or the D shape of the shaft and shrunk them with my hot air station at about 200 degrees taking care not to heat up the encoders too much.Then I slipped on the knobs with some force and they secured quite nicely.Only con really is that more force is needed to get them off again but i'd rather that than having loose knobs getting lost!Hope this is of use to people. -

Just now, Hawkeye said:

@Smithy, super cool and very nicely done! What was your total time to build it? 8-10 hours? Now awaiting your first official jam with it! :)

Many greets!

Peter

Lost count!

Friday i spent most the day, saturday a half day, Sunday a half day, Monday most of the day, and finished it before lunch on Tuesday.

But i take my time with things like this, and encountered a few problems like trying to fit the microcontroller in and cut all the legs!

I think i was being overly cautious with cutting those pins as close as possible. -

Here's the time lapse video i recorded of the LoopA.

I gave up on the solder paste and hot air method early in the build, as the solder paste I used didnt come with a plunger and my plunger was a bit too narrow.

I have officially converted over to drag soldering now and its much faster.

When I soldered the Mattias switches the recording stopped as a calendar notification popped up on the phone!

Luckily its 99% of it is there!

Thanks again to everyone involved,

everyone is credited at the end of the video.-

1

1

-

Troubleshooting midiphy SEQ v4+

in MIDIbox SEQ

Posted

Here's the Isolated Resistor Network also on RS:

https://ie.rs-online.com/web/p/resistor-networks-resistor-arrays/7884066/