-

Posts

2,524 -

Joined

-

Last visited

-

Days Won

149

Content Type

Profiles

Forums

Blogs

Gallery

Posts posted by latigid on

-

-

Hi Tim,

It's an interesting idea for sure! IMO the midiphy front panel would better suit your needs as you have more direct feeling for what is going on (16 direct tracks, haptic memory of the 8 buttons for selection row changes). Not so useful are all of the LED indicators...

As for potential mods, there is certainly scope to do this. For something totally non-invasive, you could consider using the DB-25 expansion port and rewriting an SPI driver in place of the analogue out module?

Not sure how feasible it is, but you could also use the USB host if you can write a driver for a USB connected device? I was actually thinking of something like a braille display that mirrors/converts the text on the screens somehow?

You might also be able to either replace the I2C MIDI module with something or use the spare I2C bus.

Best,

Andy -

DnB beats always appreciated :)

-

My apologies, that would be R14/R15 to IC4.

Also check if any of R9-R16 are shorted to the adjacent resistor (the pins closer to the 595 would also indicate shorts on the IC pins).

-

4 hours ago, Smithy said:

Any suggestions for a noob on how to read voltages in the appropriate places without frying the boards? :P

Find a spot to clip your 0V lead e.g. the middle pin of the slide switch on the USB board, or solder a wire to the middle pin of the power headers there. Then just go through point to point, measure on the chips, the RJs etc.

BTW, does fluxtest.NGR run properly?

-

Just to ask the obvious: are your resistor networks soldered on the right way?

As you have a working lemec_L board, you can probe around for voltages and see where things differ.

The parts that drive the fourth column of LEDs are:

Matrix column RJ4/ RJ8, T15/16 (front side), R24/R25, IC4 pins 1/15.

If the rest of the LEDs in the rows work, then there is no issue with the sink sides of the matrix.

-

Not easy to debug sorry...

Basically there is no reason that you should get matrix DIN toggle events when rotating an encoder. There might be some sort of unintentional short between the boards (e.g. from a diode and you push the encoder button?).

IC3 is the shift register responsible for the input side of the matrix, so maybe run the hot air around there or consider replacing that chip? The associated pull up/RN is right next to it

-

For example at Schaeffer (Front Panel Express):

QuotePerspex

Acrylic glass (Plexiglas®) is particularly suitable for display windows. We stock transparent acrylic glass in the material thicknesses 2, 3 and 4 mm and red acrylic glass (semi-transparent) in 3 mm.You would need to design a stepped window but it can be done! Maybe there is a design file around. Another way is just to use a thin sheet of whatever colour, either with or without a clear window. But if your panel is thick, a nice window looks subjectively better.

-

What output do you get from MIOS Studio with "set debug on"? The encoders are directly connected to 165 inputs, so IC4 is not involved here.

Looks like there are a lot of blobs around IC3?

Encoder pins connect to Plate J1, pins 8 and 9, if that helps. The encoder shouldn't hit anything below it, but you could try to slip a piece of card in between the boards to rule out unintentional short circuits.

R13 does go to pin 3 of that IC. But make sure that it doesn't connect anywhere else.

-

You could use a white OLED (or LCD...) and a red acrylic screen protector.

-

10 minutes ago, Smithy said:

Andy can you confirm that pin 13 in IC5 is linked to Encoder 6 before I order the replacement SN74HC165?

Thanks!That's right! Not sure exactly what your issue is here, but if you've narrowed it down to pin 13, IC5, you could bodge wire it to pin 3 on J5? Pin 1 of the connector has a square pad.

-

12 minutes ago, Smithy said:

I trusted my cutting of the RJ leads and went ahead and de-soldered all the Mattias switches in the Lemec PCB.

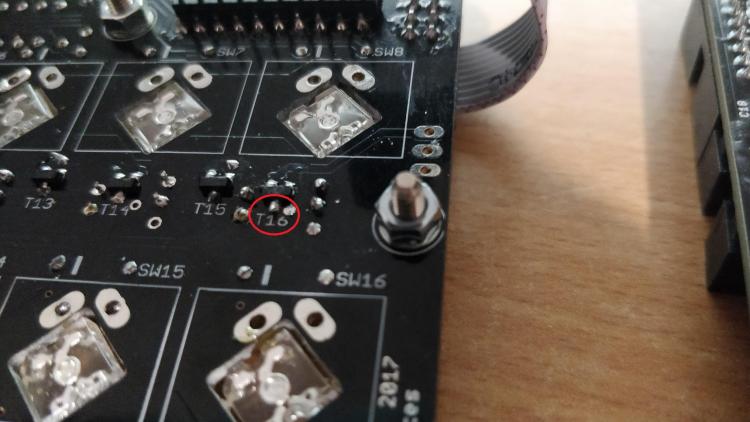

Turns out there was a short between the bottom leg of T16 and the unused pad to the right of it!Thank god for my desoldering station otherwise this would have taken much longer, if i could even do it all with a manual pump!

I owe you an expensive beer when I'm done!

I'm going to test the superflux leds now with the diode test on my multimeter in case the heat has damaged them.

I also found an issue in the RH Lemec board earlier.Turning Encoder 4 lights up the LEDs in the 3 switches below it. I'll post more detail on that later.

Clean work, you're doing great! That is a via that brings the SR signal to the transistor.

-

28 minutes ago, Smithy said:

fixed the image.

Thanks, it works. Can't see anything obvious. You can check the components I mentioned before. It could also be a too-long resistor leg, also on RJs? Before desoldering all of the switches, you might try to remove those resistors.

-

41 minutes ago, Smithy said:

I tried soldering a bridge between pin 15 and pin 16 of IC4 and no luck. The 4 leds still light when seq_l is loaded. I presume thats exactly what I was meant to do?

What I meant was to desolder a potential bridge there. Generally you don't want the output shorted to the power supply. But a constant voltage here would mean that the transistor base was always in the high state and not able to switch as required with the 595 pulses.

41 minutes ago, Smithy said:I just have to remove the switch caps and light shields to be able to separate the boards again I presume?

I guess that's the case... light|shields and keycaps can stay on!

-

I could not see your picture of the soldering

As the behaviour is common to a column (two columns, but they are only separated by RJ4/8) it is probably caused by

1. Wrong transistor type or otherwise an error with T16. Yep, that's on the top side of lemec_L!

2. The pin driving T16, so R16 and IC4, pin 15. With luck you just have a solder bridge to +5V (pin 16).Good luck!

-

Nice! Just be certain to solder the LED anode in the encircled pin, maybe test before soldering. It sucks to remove them if they are the wrong way around! But you probably already know this joy from the JA PCB.

-

3 minutes ago, Smithy said:

Just checked the Erata for that pcb on the wiki and it says:

The C3 cathode row is missing a PCB trace. Join the two legs of SW19 as shown in pink, preferably on the bottom of the PCB. The LED cathode leg could simply be bent across to the switch pin.

http://www.midibox.org/dokuwiki/doku.php?id=seqv4plus_le_mec

Will give this a go!Also a good catch, I had forgotten about that! There is not much risk in soldering in the MEC switches. It is only the Matias switches that you really want to be sure about because once they go in you have to desolder all of them to get to the inside of the PCB stacks (BC808s).

-

-

The 3M headers seemed to be easy to source and typically had good stock. It is also less effort to keep track of one part series. The 6mm "standard" single-row header might work (see above post) but the extra fractions of a mm help. That is why the 8.08mm part was ordered. Feel free to stick with 8mm. The same TE part on Mouser/Digikey is discontinued.

Remember that the TE part you found has a plastic base height of 2.8mm, whereas the 3M one is "only" 2.54. So already there is a difference of 1mm.

-

There are two types of SMT resistor networks in the SEQ v4+. The bussed one on the JA board and two isolated on lemec_R to serve as current limiting for the activity matrix. Just use the product page to make sure you're ordering 8x resistors in a 16-pin package. If there are 15 resistors, that's the bussed one. (Seems like your RS part is good.)

(There are also bussed THT arrays on lemec boards)

For the pin headers, even normal length ones could work but they tend not to make good enough contact. Adding up the thicknesses:

connector 5mm

PCB 1.6mm

inter-PCB spacing 3mm- plastic thickness 2.8mm

6.8mm of pin

So I would suggest 826630, or actually 826935 as it matches the tin plating better. The 8mm one that you found would probably still work, just be aware that if it sticks through the header too much, it might contact the case.

-

I just hope that it wasn't 3x BAT54 on top of each transistor ;-)

This approach works best I found when the solder has burned through its flux. If it's too hard, you could consider a fleck of copper tape or a strand of wire.

-

For v1.3_R

Omit:

IC6 (74HC123)

C6 (or leave it in, no difference)

C7 (top side)

R17 (top side)Stuff:

R26 (1-10k) or bridge it.

-

You will probably get bad ghosting without the BAT54s. Short of ordering a new board, just "stack" the BAT54s 1:1 on top of the BC818s, so with the text still facing up for both transistor and diode.

Please stuff R17 (any value up to 10k) or simply bridge it. C6 and the nearby diode can be left unpopulated.

-

Awesome work!

-

No need to replace that pad, pin 1 does not connect to anything.

Best,

Andy

midiphy SEQ v4+

in MIDIbox SEQ

Posted

That I am not sure of. There are also unused functions e.g. the footswitch and gate.

It would be possible to remap any button without recoding by assigning it in the HWCFG. But I am not sure what function to put on the datawheel. I think I once asked if it could be an enter key or similar but I am not sure where/how that makes sense.