FantomXR

Members-

Posts

1,035 -

Joined

-

Last visited

-

Days Won

22

Content Type

Profiles

Forums

Blogs

Gallery

Everything posted by FantomXR

-

RANGE command does not work with Receives / Senders

FantomXR replied to FantomXR's topic in MIDIbox NG

This might also be valid only for the velocity but I'll give it a try! -

RANGE command does not work with Receives / Senders

FantomXR replied to FantomXR's topic in MIDIbox NG

Thanks for your reply. How could "if_" help here? What I now did (and what worked) is to create an EVENT_RECEIVER for every single note like EVENT_RECEIVER id=1 type=NoteOn key=20 fwd_id=SENDER:1 EVENT_RECEIVER id=1 type=NoteOn key=21 fwd_id=SENDER:1 EVENT_RECEIVER id=1 type=NoteOn key=22 fwd_id=SENDER:1 Since they all listen to the same ID, its easy to activate / deactivate that with meta events. This is not beautiful because it's a lot of code. But at least its a working solution ;-) -

Hey, I'm trying to split an incoming MIDI signal into two zones just like this: EVENT_RECEIVER id=1 type=NoteOn key=any fwd_id=SENDER:1 range=0:36 EVENT_SENDER id=1 type=NoteOn key=any range=0:36 chn=1 ports=100010000000 EVENT_RECEIVER id=2 type=NoteOn key=any fwd_id=SENDER:2 range=36:127 EVENT_SENDER id=2 type=NoteOn key=any range=37:127 chn=2 ports=100010000000 Unfortunately the "range" parameter has absolutely no effect here. Regardless what values I enter, it does output two NoteOns for each key (one on ch.1 the other on ch.2) over the whole range. It does have an effect on the velocity though. I could limit the velocity through the range-parameter. But thats not what I want to do :-) Is that a bug in the firmware? And if yes, who can fix it? :-) Thanks, Chris

-

Hey, for sale: GM5x5x5 PCB STM32F4 Disco Waveshare Core STM32F4 Core LPC17 Core Selling for best offer. Chris

-

For sale are 10pc PSM01-081A-103B2 Motorfaders. Never used. Brand new. Selling all of 100€ or make me an offer.

-

Hello, I'm selling stuff. Anybody in the need of something? - FATAR Pitch & Modwheel: 20€ - FATAR 61 TP/8O (new): 100€ - FATAR 61 TP/8O + Aftertouch (new): 100€ - FATAR 76 TP/40M (new & used): 150€ - FATAR 76 TP/8 Piano (used): 50€ - FATAR 76 TP/8SK (used): 50€ - FATAR 76 TP/9S (new): 100€ - FATAR 88 TP/40 (used): 100€ I don't sell electronics. Best, Chris

-

Hey people, I'm sure I do overlook something. I'd like to display the CC number that is send by a fader connected to the MIDIbox running NG. To display the value is easy with label="%3d". But how about the CC-number itself? And the channel? Thanks, Chris

-

I'd like to catch up on this topic because I ran into a problem. I've connected two NG-cores with a direct connection without optocoupler and stuff. The only thing that I've added is a 1k pullup to +5V at the midi-inputs. I use the fourth MIDI I/O on the first core and the first MIDI I/O on the second core. The first core is connected to a computer via USB. I've added a router-setting so that the fourth MIDI I/O is routed to the second USB port. That allows me to access the second core which works great so far. I can access the SD Card through MIOS Studio of both cores. Fine! But: When I try to write a file to the SD card of the second core I do get an error message: ERROR: the application has requested file position 0x00000140, but filebrowser expected 0x000000120! Please check with TK! The numbers are differing from time to time. Also it seems to be related to the size of the text-file. I can perfectly write a simple file with RESET_HW and a few router-settings. But as soon as it has some more lines / rows, it gives me that error message. I'm not sure why. I double checked the firmware at my side and also tried the original firmware from TK. No luck so far. Any ideas? Thanks, Chris

-

I'd like to join in here! I'm still looking for a way to midify an instrument using MIDIbox. May I ask you which sensors do you use @zaordsword? And is there a way to include a velocity calculation using AINSER64? It's quite easy to set a Note-On Trigger using MAPs. But the electronic would need a second "point" to calculate the resulting velocity. Any ideas?

-

Hey, I want to get rid of these. They worked fine when I removed them from my build some years ago. Since then they were stored in a locker. Since I have no chance to test them I'll sell them as non working (although I'm pretty sure they work well). I'm asking 15€/pc for the CP K Fader (I have 6 in total) and 45€ for the bulk in silver. Those prices are just an orientation. If you are interested, drop me PM and we will see. I really don't need them anymore. Best, Chris

-

Hi Andreas, if you use the NG-App for this task, you will end up with a quite bad velocity resolution. You only will get about 16 different velocity values or so instead of 127. This is due to the lower scan rate. If you want the full resolution, you'd need to take KB.

- 19 replies

-

- midibox kb

- fatar

-

(and 2 more)

Tagged with:

-

If you are up for the best performance and you don't want to dig into code: use both with two separate Cores. KB can't really handle LCD displays, pots und push buttons. On the other hand NG is not optimized for keyboard-scanning. The scanrate is a a lot (!) slower. And you will get a very low velocity resolution. Maybe 20 values out of 127 or so.

-

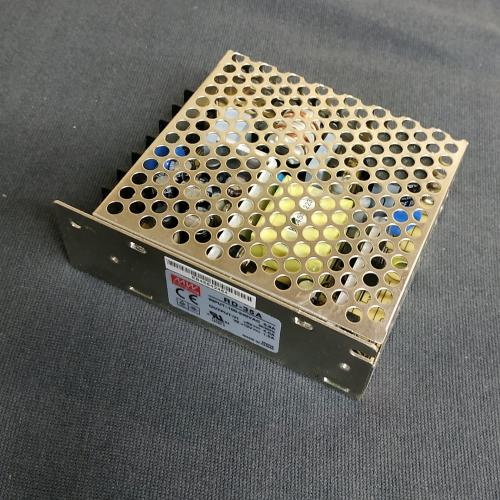

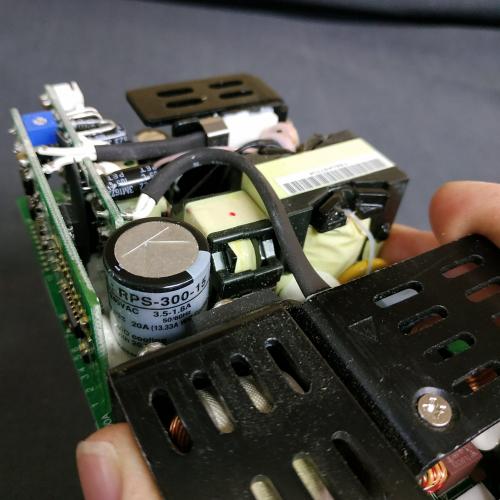

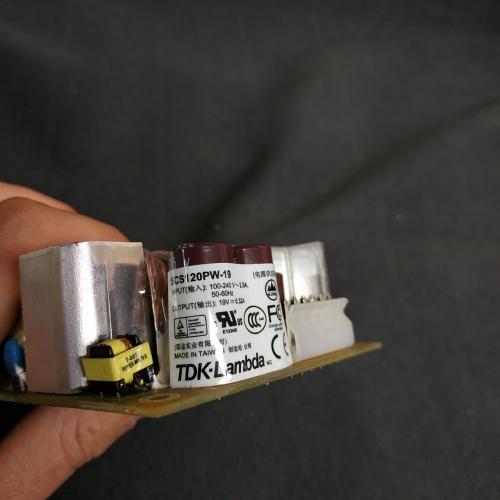

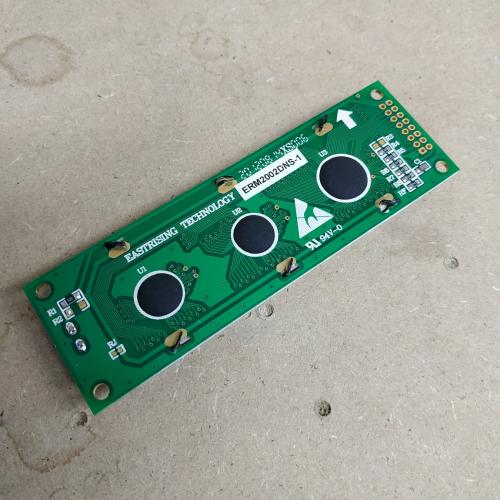

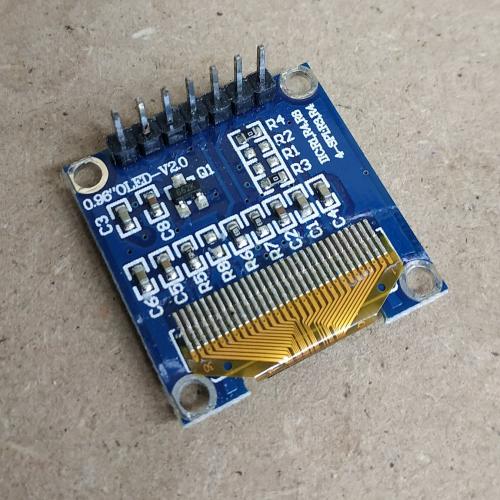

Hey people, I clean up my workshop. Here is a list of stuff that I don't need anymore. JWS100A - 12V: 50€ Meanwell EPS-35-5: 5€ Meanwell LRS 50-5: 5€ Meanwell LRS-350-15: 15€ Meanwell RD-35A: 5€ Meanwell RPS-300-15: 30€ Meanwell UHP-350-12: 40€ TDK Lamda SCS120PW-19: 35€ CLCD: ERM4002DNS 5€ OLED01: NHD-2.7-12864UCW3 20€ OLED02: Standard 0.96" OLED - SPI + white text 3€ / pc. OLED03: Standard 0.96" OLED - blue text 3€ / pc.

-

It works great with the correct PIC18F452 ;-)

-

Thanks! I'll order a 452 and try again... Thanks, Chris

-

I've just noticed, I've used the PIC18F4520 instead of PIC18F452. Could that be the problem?

-

http://midibox.org/forums/topic/21329-adafruit-trelli/#comment-186377 https://www.dropbox.com/s/c9c0jklz28nhe2r/VID_20200407_105633.mp4?dl=0

-

From the album: MIDIBox Trellis

-

From the album: MIDIBox Trellis

-

From the album: MIDIBox Trellis

-

And another video: https://www.dropbox.com/s/3tlwui62v8ot5ls/VID_20200407_171420.mp4?dl=0

-

From the album: MIDIBox Trellis

-

$12 only if you want me to do the SMD assembly. If you do it by yourself it's $8 + $1 for soldering-parts and $5 for elastomer. ;-)

-

You only need a few 10k 0805 resistors, 2x 74HC165 in SMD and 100n 0805 filter cap. That's it. If you want you can add a 10u 3216 Tantal-Cap to the input of the LEDs. There is a footprint for it. So all in all less than $1 or so for parts for 1 module.