-

Posts

1,285 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Gallery

Everything posted by Phatline

-

[S] 7x MB-LRE8x2 CS Rev 2.5 (fully stuffed with parts)

Phatline replied to Phatline's topic in Fleamarket

the rest off them are now sold to @wlinart can be closed - thx. -

MB6582 passive cooled (purple and green SCREEN/LEDs)

Phatline replied to Phatline's topic in MIDIbox SID

-

MB6582 passive cooled (purple and green SCREEN/LEDs)

Phatline replied to Phatline's topic in MIDIbox SID

-

USB host doesn't work but i follow the TK topic

Phatline replied to xarolium's topic in Testing/Troubleshooting

you sayd you made a custom USB OTG cable... you think you have done it right (ID PIN ??? )? if you have done right, maybe you have wrong bootloader settings: (http://www.ucapps.de/mios32_bootstrap_newbies.html ) -

USB host doesn't work but i follow the TK topic

Phatline replied to xarolium's topic in Testing/Troubleshooting

done this? #undef MIOS32_DONT_USE_USB_HOST ? no just remove the line.... -

i programmed a max for live patch for it to move a 12x16 Grid launchbox, mute,arm,solo,stop... plus a midiclip editor... which is work in progress... http://wiki.midibox.org/doku.php?id=triggermatrix5#software

-

new price 750€ i combined and wrote the 32bit Code so it now can comunicate with a SEQV4+, and off course with the SEQV4 standard, here is the sourcecode + firmware: BLM_V01.7z see also this short video (german):

-

try: upload the newest bootloader (with mios studio + http://www.ucapps.de/mios32/mios32_bootloader_v1_018.zip), reboot, on mios-studio - go to the mios-terminal-section, and type "help", then change to LCD type, the number off characters (2x40) and the numbers off X and Y Screens you have on your sequencer... then type "store" (was it store...save...? no idea, all commands are listed when you type "help") the core reboots and you will see some Text on your screens - then you have prooved that this is no hardware issue, then upload the newest LPC17 Seq V4 firmware, then report if it is still Black Blocks you see. by the way is your "orginal old core setup"? has the LPC-core ever worked? if not, try to replace the HC595 chip on it (IC2), also check the solderpoints that have to do with the LCD-Section (see the shematic: http://www.ucapps.de/mbhp/mbhp_core_lpc17.pdf) ... Specially the groundpins, since we have a ground plane here, the plane sucks away the heat coming from the soldering iron, give enough heat on your solderstation, and heat the pins longer then normal... but bevore remove the lpc board, and IC2, so you dont destroy them... thats all - what comes in my mind.

-

ok - i wrote sauren. if i get feedback from him - that he have a pcb - then i ask you @Smithy again - if you still have a pcb-frontpanel then. - mike.

-

hei, what do you payed on jlpcb for one set (devidet)? is there a change to get a Sauren Frontpanel PCB anywhere? - i am interested - but not sure that i get all i need to build this (the FM-PCBs are sold out - as example: https://midiboxshop.bigcartel.com/product/midibox-quad-genesis-board)

-

maybe its the Ripple off the PSU about your PSU - reichelt specs is saying : "Ondulation résiduelle : 80 mVcàc" i guess this is not a 50Hz ripple but HF ripple... --- i guess some small cap (100nf, 10pF) and a big Cap (depends on the load, use for example a 100uF and a 2200uF) on the output off the PSU would reduce that "ripple"... * maybe that caps are not enough and you need some more filtering (coil, resistor, lpf...) but i would start with some caps... the connections in your 2nd picture are not necessery - i guess (dont seeing the whole picture, but i think so...) --- so picture 1 is correct. by the way - its only the last LED that flickers? maybe you have to terminate the DO line on the very last LED off the Chain with a 10K resistor to 5V or Ground. else it could be a software problem, when the software loops thru the LEDs, and when it comes to the last one it jumps to the beginning off the chain... try to programm in the ng code one more LED (which in reality not exists) - so you can be sure that this is not a software bug... - but dont ask me about ng-programming --- no glue about that. - mike.

-

I sale them: 2x with wite SMD LEDS: (for Acrylic Panels without Thruhole) - these are the only two boards with ENCODERS with inbuilt pushbuttons 30€ the Pair SOLD to KSIR! 2x with RED 3mm LEDs - mounted flat to the pcb (for Acrylic Panels without Thruhole) 30€ the Pair 1x with Yellow 3mm LEDs - mounted flat to the pcb (for Acrylic Panels without Thruhole) 10€ 2x with RED 3mm LEDs for thruhole Mounting 20€ the pair I dont have Encoder-Nuts for them. Shipping only to the EU why i sell them? > i dont need them... if i am in need i would design my own pcb...

-

new price 800€ -serviced yesterday.

-

two songs in this video sequenced with Triggermatrix 5 as drum-step-sequencer and note processor, feeded with melodys coming from the LoopA

-

MB6582 passive cooled (purple and green SCREEN/LEDs)

Phatline replied to Phatline's topic in MIDIbox SID

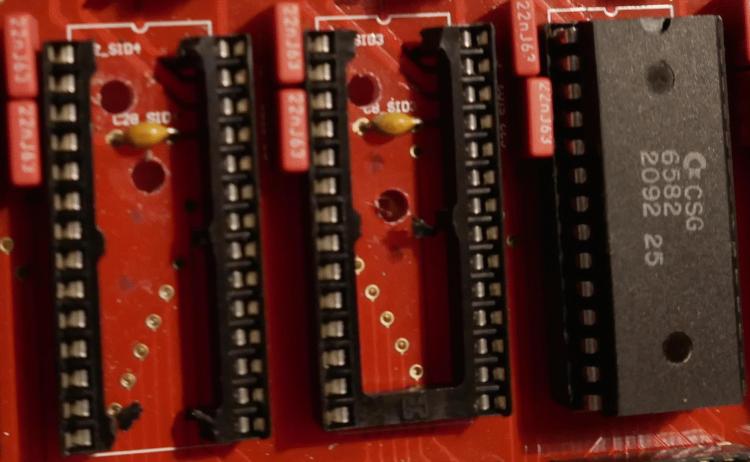

made a few changes on the cooling: more holes Made 3 holes where the ventilator "should be" Drilled the 2 M3 Mounting holes on the right to a bigger diameter Drilled a hole near the 7809 cuted also the second "bar" off the IC-Socket (left socket) - before i had only cuted the top one (see middle socket) i had fear that it would not hold in the socket, or they would bend to much... but the SID hold the socket togehter once it sits in it. so i have even more thermal pathes... lets see what this changes on temperatures: SID: 48-55C° PIC:36-37C° Bottom Case: 32-38 (on one point 45C°) 7809: 45 pcb near 7809: 32-37C° Frontpanel: 32C° Backpanel: 32C° -

well then test like i suggested: Voltmeter black cable to a ground pin (core ore dinx4 module) Voltmeter red cable to a Dinx4 Pin that is connect to a PAD. if you dont press the PAD you should have 5V (its pulled high with the Dinx4 inbuilt pull high resistor > the 10K ones) if you then press the PAD you should have 0V (its pulled down with the button that connects now the Dinx4 Pin with Ground) if this is not 0V, and in worst case 2.5V - then the Resistance between Button and Ground is to high, so the 10K resistors which are connected to +5V overrule them... the Chips on the Dinx4 recognize 5V to 2,5V as high (cant say if this is true i think its arround 2,5V) and 0-2,5V is low my suggestion is now, take one off the 10K resistor out and replace it with a 100K resistors, measure again, and see the difference. about NG: maybe ZAM knows more... i am definitvly the wrong one for NG script ;)

-

MB6582 passive cooled (purple and green SCREEN/LEDs)

Phatline replied to Phatline's topic in MIDIbox SID

Now a Purple Passive Cooled is alive: Temperatures after 1,5h: Front panel: 29-31C° Bottom off the Box: 30-43C° Back panel: 28-40C° (40C° on the Plastic above the Ventilator-Air-Hole, 33C° above the small Air holes) SID-Chips: 45-54C° 7809: 44C° PCB near 7809: 40°C PICs: 36°C I will drill some more holes, and post some measurements later on. this picture is near off the Color that it in reality has... but the camera cant face this UV things good: here where the case color is like it looks in reality (but not the LEDs) back plate, with some AIR Holes, since it is a passive Cooled Design: I made a single PSU option (+12VDC) that on the 5V Rail i used a Traco Power Switching Regulator (which is cool) on the 9V Rail i used a standard 7809, which i mounted on a ALU-Cooler, which i mounted with thermal paste everywhere around on the PCB, the screw thru the PCB i fastened again with thermal paste everywhere, on the blank Ground-Plane off the PCB, On the bottom off the Case i made a lot off Holes so Air can get in... (the 2 holes under the SID is a Air Intake, and i also cut away the plastic off the DIP-Socket so Hot Air behind the SID can get away.... there are also holes on the bottom off the Case for some Air intake!) (i drilled away some plastic from the MIDI-Sockets, and also from the PCB , so i can safely mount a Power-plug into the back panel, the Takeaway from the PCB is also some way to get rid off some hot air, coming from the underside off the PCB where the 7809 produces heat) In this picture you see that i soldered a 220nF Cap between the Reset Line and Ground off the SID... this took a way a high chirping sound out off the equal loud noise floor... I tried different other things to reduce noise, switching a 9V Switching Regulator to a standard 7809 made nothing hear able difference, also by adding LC Filters on the 5V Rail changed anything... this 220nF made the most difference in sound quality (and off course the EXT-IN>Ground Jumper :) (attention the first sid/downer is the correct soldered Cap, the 2nd i mistaken solderd to the wrong pin) (the screw is the Thermalthienk for the 7809) single wires to the Frontpanel is for me the best solution: i also used on the whole PCBs Pb Solder, the melt with slower temperature, and is more fluid, this is good for this PCB because the VIA Spacing between Solder point and Groundplane is almost not existent, so Shorts cant happen so easy... -

since you dont use a Button Led Matrix on this - where the driver is already programmed to be debounced... and you on the other hand connect the buttons directly to a DIN-Module - which i didnt have done yet, on the hardware side i would take a Voltmeter, and measure on the DIN-Pins, hand look how many Volts you have when you press the button... if it is 0V then all is good, if it is hardly above that, then you may change the Pull-Hi Resistors on the DIN Board to a other (higher) Value (As expiriment) - because the Rubber button is not a perfect Electric Contact (a tactil switch is more on "perfect) it might be that it cant Pull-Lo the Pull-Hi resistors (fighting) @ software you have to debounce the buttons in software - how? i dont know the NG-script - so i cant help much here... maybe you start by posting how you defined the buttons in ng code... maybe i can see there something... It could be that there are set as toggle switches, in reality we wont some momentary switch - ... maybe there is also some timining offset to be set (a time that says that no incoming DIN signal is handeld after a trigger accoured - so we avoid false triggering for example 20ms long... aka debouncing?)

-

all encs are working? so its confirmed they start count with nr 1? thx 4 info.

-

are you sure that Encoders start with Number 1? At least on Midibox-platform on the codeside (if you write a custom Midiboxproject) normally they start with Number 0, (also Buttons, AIN, Midichannels, CCs, Notes, i guess also Ledrings? ;) ;) ...) that would look there like this: const mios32_enc_config_t encoders[3] = {//(SR count-begin with 1, ENC with 0) // setup the Pinout of Encoders { .cfg.type=DETENTED1, .cfg.speed=SLOW, .cfg.speed_par=1, .cfg.sr=8, .cfg.pos=0 }, // 0 PAGE { .cfg.type=DETENTED1, .cfg.speed=SLOW, .cfg.speed_par=3, .cfg.sr=8, .cfg.pos=2 }, // 1 PAR 1 { .cfg.type=DETENTED1, .cfg.speed=SLOW, .cfg.speed_par=3, .cfg.sr=8, .cfg.pos=4 }}; // 2 PAR 2 u8 i; for(i=0; i<3; ++i) { MIOS32_ENC_ConfigSet(i, encoders); } they start with 0.... no idea if Thorsten, made it more "musican friendly" by make an offset "+1" behind the userinterface - so they start with 1 on Midibox NG? my nose says.... give it a try: ENC n= 1 sr= 1 pins=1:0 type=non_detented ENC n= 0 sr= 1 pins=3:2 type=non_detented ENC n= 3 sr= 1 pins=5:4 type=non_detented ENC n= 2 sr= 1 pins=7:6 type=non_detented ENC n= 5 sr= 2 pins=1:0 type=non_detented ENC n= 4 sr= 2 pins=3:2 type=non_detented ENC n= 7 sr= 2 pins=5:4 type=non_detented ENC n= 6 sr= 2 pins=7:6 type=non_detented ENC n= 9 sr= 3 pins=1:0 type=non_detented ENC n= 8 sr= 3 pins=3:2 type=non_detented ENC n= 11 sr= 3 pins=5:4 type=non_detented ENC n= 10 sr= 3 pins=7:6 type=non_detented ENC n= 13 sr= 4 pins=1:0 type=non_detented ENC n= 12 sr= 4 pins=3:2 type=non_detented ENC n= 15 sr= 4 pins=5:4 type=non_detented ENC n= 14 sr= 4 pins=7:6 type=non_detented

-

EDIT: First try my second post (see below this one) try to not assign Encoder 16, and watch which 2 Buttons now are see-able in mios studio when turning the ENC 16 --- is it 29 30? since ENC15 is outputet as Buttons 31 32 in Mios Studio - so we can check if it is a neightbar on SR4... How ever - i guess you use a encoder pcb which you use 2 times in your setup, so ENC 7 is the same as ENC 15? and ENC7 is working as it should? try to to not assign ENC 7+8 - it should be the same pinout like ENC15+16 (but a other Shiftregister) some math: when ENC 15 is equivalent to Button 31 + 32, then ENC 7 movements should be button events = 32-16 = button 15/16, and ENC8 would be? 13/14? if so > 14+16 = 30 31 should be then Encoder 16? i checked your shematics, and there is no change to wrongly assamble the sandwitch (the button pins are always on the outside of the Header J30-J33 - so this cant be the bug... i guess u use standard DINx4 Modules to connect the boards, so a wrong pinout from this side cant be the bug too... at NG Code i am familar with assigning Encoders to shiftregisters and pins > and it seems ok to me (when it is correct that Encoders starting at ENC Nr1 and not at ENC Nr0?)... about the rest of NG i have no glue.

-

j2/j17 should do the trick yes.