FantomXR

Members-

Posts

1,035 -

Joined

-

Last visited

-

Days Won

22

Content Type

Profiles

Forums

Blogs

Gallery

Everything posted by FantomXR

-

@Antichambre: You can order them at chia shin. But MOQ is 1000pc.

-

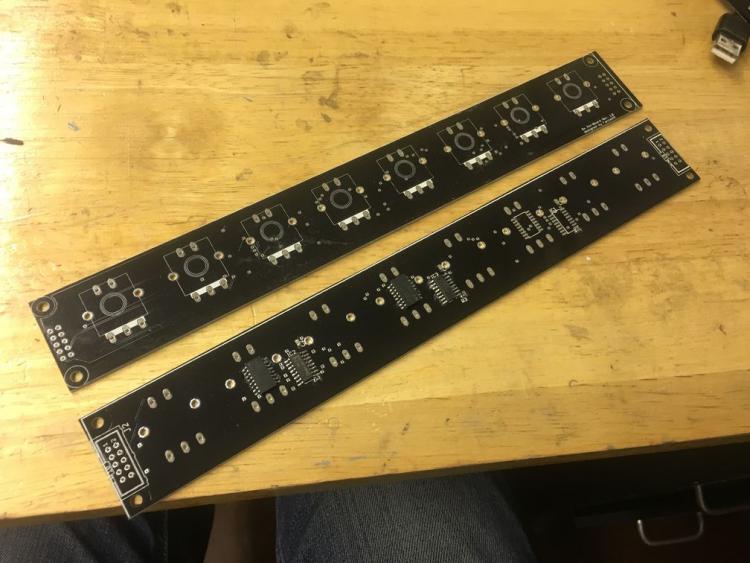

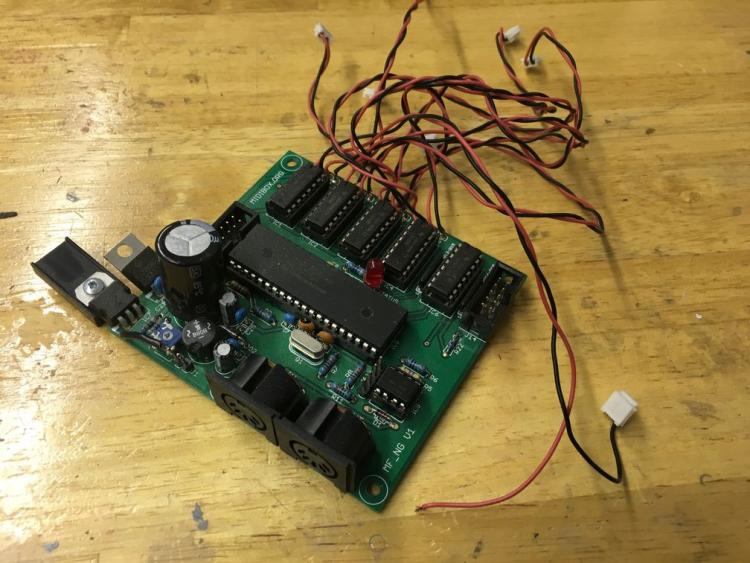

Hey people, I'd like to get rid of some stuff I do not need anymore. Some PCBs are assembled already. Here we go: LPC17-Core-PCB: Price: 5€ / pc. LPC1769-uC Rev. C: Price: 15€ Encoder-PCB (shiftregisters & resistors are SMD (and not mounted) but easy to solder with a good soldering iron): Price: 5€ / pc. Encoder-PCB (all parts mounted. The first encoder is detented. I'll remove the caps): Price: 15€ I'm in Germany. Best, Chris

-

@Zam: Just a quick note on this: I tested several things on my PCBs but I was not able to get rid off these value-jumping-issues when changing the colors on my WS2812B. After researching I found a little chip called MCP1541 from microchip. This generates a super stable reference voltage for the MCP3208 out of 5V. Even out of the noisy USB-5V. And this solved all problems. Such a great IC. Also very low component count. MCP1541 + 2 caps and you are done.

-

How many do you need? I just received 40pc.

-

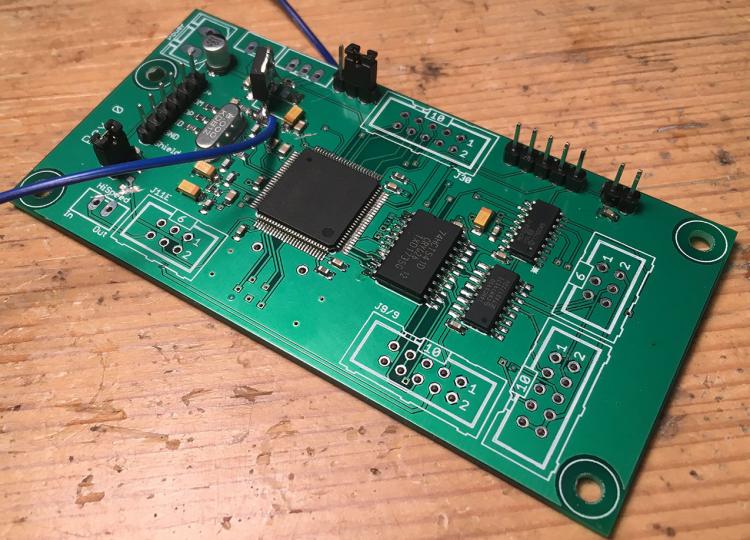

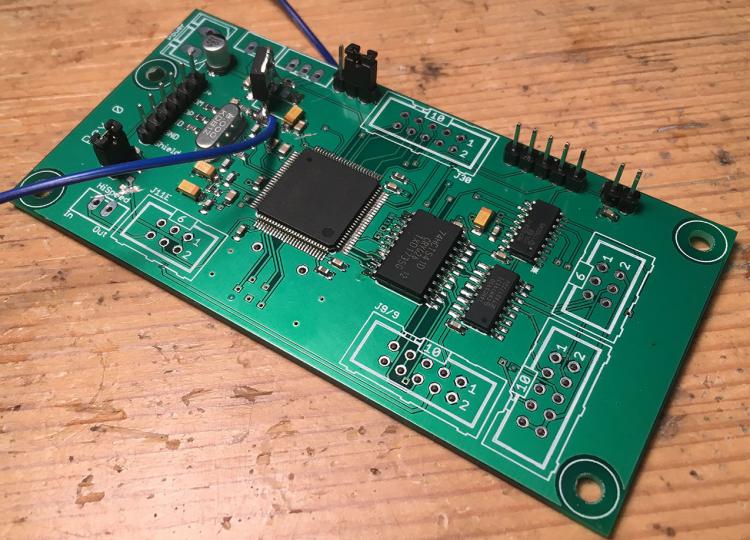

Hey people, since I'd like to be independent from the availability of the STM32F4-discovery board I started designing my own board, which has an STM32F407VGT6 on board. Its an LFQP 100 package, so not easy to solder. I have a reflow oven and the first PCB I made seems to work fine. The PCB has very few components. This was just a quick test board to see if the basic circuit of the STM32F4 is working. It's basically just the STM itself and it's components like caps and crystal. Also there is a 3.3V regulator (based on 1117 but will change to TC2117) to power the uC. I added a pinheader for USB connection (on the very left), a pinheader for SWD to flash the bootloader and a reset-header. On the right you see the HCT541, which connects to J8/9 (tested: works fine). Also I added an MCP3208 and HC595 for an AINSER64-like-analog-scanning. On the bottom of the PCB there is a MicroSD-slot. No changes in the firmware are needed to use this. The only thing one need to do is flashing the bootloader the first time. @latigid on made a nice "how-to": http://wiki.midibox.org/doku.php?id=wcore After that you can use the MIOS as is. So, why I'm telling you this? This core is already very specific for my applications. But if you are interested I could upload the minimal circuit for the STM32F4 to work and you could add all headers and components that YOU need by yourself. So in theory you could recreate the original MIDIbox core but you should end up with a much smaller footprint (especially regarding height). If you need assistance regarding soldering the STM32F4 I can offer to reflow-solder it for you. I'll clean up my circuit and upload it the next days! Best, Chris

-

@Alasdair Moon The discovery board is now available again on mouser.

-

My prototype-PCB arrived yesterday. I set up my reflow oven and gave it a go. I'm very happy with the result. LQFP100 is really small. But it's working! Apart from some changes I needed to make on the 3.3V power supply, it seems that I have the minimal circuit working. :-)

-

I just created a design for a core by myself and ordered it. It's downstripped (has just J8/9 + MicroSD-card reader on board) because I want to test the basic functionality of the circuit first. I'll keep you posted if it runs fine :-) If the design works, it can be easily extended to other people needs.

-

Hey people, just a short question: Is it possible to replace the SD-Card with another kind of memory f.e. FRAM? Thanks, Chris

-

@Alasdair Moon: Sorry! You are right... damn it! But yeah, looks like latigid on seems to have a solution for that.

-

https://www.mouser.de/ProductDetail/STMicroelectronics/STM32F407G-DISC1?qs=sGAEpiMZZMvt1VFuCspEMrjE4TO0IyBBeNQ%252bgqeMpN8%3d Take this one ;)

-

Easy task! Just create two EVENT_KBs with different ids but same hw_ids and set them to different channels. Regarding your second question: I think TK implemented a Learn-function a while ago. Maybe this works with KBs too. Search here for "learn": http://ucapps.de/midibox_ng_manual_ngc.html

- 9 replies

-

- midibox_kb

- midibox_ng

-

(and 1 more)

Tagged with:

-

I use PEC16 without issues.

-

Hi! Yes, there is a debounce_mechanism: SRIO debounce_cycles=<0..65535> Anyway: Improving the hardware should be better than software debouncing.

-

I'm building a lot of keyboards with MIDIbox and space is a problem at any time. So the main reason is, to create a PCB, that has just those components on board, which are necessary for that application (including the shift registers for scanning). This would save space and cables. Like I said: The Wavecore seems to be a huge improvement already. So I'm curious if latigid is willing to share his project ;) Maybe you are right: I could go through all schematics of those boards which are on the market. But as you said: This is really time consuming. I took a look into the waveshare-407-schematic. This looks promising! Very few parts and a good oversight. The datasheet of the disco-board is really killing...

-

Thanks for your suggestions! @latigid on: Your design has a big advantage: I hate those Micro-USB connectors on the DISCO-board. So this will be a huge improvement. Also it looks a bit smaller as the DISCO-board. How about the PCBs? Do you plan to upload the layout? I designed my own breakout-board for the DISCO-board. So it has a bunch of connectors that the MIDIbox-core doesn't have. Also some regulators and another micro-sd-card slot. I'd like to take your design, make those changes and give it a try. Is there any chance to get the eagle-files from you? @Antichambre: I've read in the link you posted that you already designed an own stm32f4-PCB. Any progress on this? To be honest: I'd really like to create my own stm32f4-PCB. But I have no clue about what is needed for a minimal circuit. Your PCB looks like it has everything on board and I just need to make my modifications to it. SMD soldering is not a problem. I have a reflow oven. We could also think of a core, that is especially made for midibox-users. I could make them in my reflow oven and sell them to others if there is any interest.

-

Hey people, I took a look into the drivers that come with MIOS. It seems that all STM32F4xx could be supported. Is that right? I ask because I'm looking for a smaller alternative to the DISCOVERY-board which has a big footprint. Here f.e. you can find a much smaller board with has a STM32F405 on board: http://re.reworld.eu/de/produkte/s64dil-405/index.htm Any informations on this? Best, Chris

-

This might be possible with using the SET ^chn command in an NGR (which again is triggered by a button / switch),. Same here! Please see here:

-

Hi Frank, yes. That is possible. You can achieve that by using a NGR-script, that sets break_is_make on. This script you need to trigger with the switch.

-

Hm... I'm using NG in keyboards for a few years now and as far as I remember I never had the issue, that notes are not being played. I enable make_debounce on my keyboards. Without that sometimes note-off is not being send (IIRC). As NG does not support 3-contact-keybeds at the moment it needs both contacts to be opened before sending the next note-on. Without both switches opened NG can not calculate the velocity so it's not being send. If "break_is_make on" works for you, it's quite clear, because break_is_make doesn't wait for both switches to be released.

-

My tests with NG vs KB had the result that no matter what I change in the official NG-app, I'll never get those fine velocity steps, that KB gives. So I created my own NG app and kicked out all of the functions, I do not need. There is a thread about it in this forum. Just use the search engine and you'll find it quick. Anyway: I still feel, that KB outputs more velocity values as my NG does still. So I think it depends on your needs. Btw: please be aware, that there is no octave shift function (regarding if NG or KB) yet

-

Yes @Zam you are right. I had issues with those LEDs. But since I use a separate PSU for the LEDs the problem is gone! ;-) Well, I'm still not able to run the faders in 11bit because of jitter (regardless if the LEDs are connected or not) but I really don't need that. 7bit is sufficient.... and thats another topic ;-) I also made a design-mistake: The VDD-traces on the LED-PCBs are way too thin. I used about 0,6mm which might not be enough for this current. I expect a current of above 2A when changing the color for the LEDs. Of course I never run them at full brightness! Then they would draw MUCH more. But yes: If you think we would be able to make something "better", than start another topic. I'm happy to help! (but I'm on vacation from tomorrow on ;-) )

-

Like I wrote somewhere on the forum before: if you want to connect an 61key Fatar keybed to DIO matrix you do not (!) need any kind of adapter PCB. Just use two 16pin ribbon cables and twist them by 180 degrees.

-

So I now did some changes: I added an 68pF (I had this in stock... I had no other value available without visiting the next electronic shop) ceramic cap between SCLK and GND at the very end of the OLED-Chain. I also added a 10uF on the IDC connector of the OLEDs between VDD and GND. I also added a 100uF on the WS2812B connector. I checked again the wiring and it seemed that the OLEDs were connected to the same power supply as the LEDs. So I changed that! The OLEDs are now powered from a separate PSU. I didn't have time to put the MeanWell PSU into the device... this is a lot of work... I'll do next year ;-) I'll keep testing the device in the next days / weeks and report back! Thanks!!