-

Posts

2,524 -

Joined

-

Last visited

-

Days Won

149

Content Type

Profiles

Forums

Blogs

Gallery

Posts posted by latigid on

-

-

I'm finally done soldering the parts (except the sliders). Whew! I've installed the blm_scalar software on the PIC using an old core board. What unused AIN pins do I need to jumper on J5B? I can't really tell from the pictures.

This view of the board has J5B on the rear. So four pairs of AIN should be jumpered to ground towards the middle of the PCB, the bottom-most is +5V and shouldn't be shorted.

The instructions show the cable pin connections between the din8 connector and the minicore board on the blm. What about on the other side, between another din8 connector and the seq4 core? I'm still using a LPC17. What should that look like?

Do you have the Quad IIC installed? If not, you need to provide another MIDI connection (the input of which should be optoisolated). You can supply power via the DIN or else by using the extra case holes for a separate power connection/regulator.

-

Smart move! The little notches in the top left corner were meant to be for a diode jig but unfortunately I didn't quite get the distance right.

Best of luck for the remaining parts.

-

Something else to check is the orientation of resistor networks, they have a dot which must align with the PCB legend.

To test if the chip survived, you could try to swap some around and see if you can get a bit of functionality.

Depending on the buttons you ordered, it is still possible to misalign these by 90 degrees.

-

I found a few (old, like 25 y/o VSOP!) "Eurorack" PSUs. Not in the modular synth style but built for DIN rail electronics. They offer 5V 3A and +/-12V 0.3A. It's a linear design with a large transformer and heat sink, but uses LM723 as a precision rectifier and driver transistors to boost the current. I should really replace the old caps but at the moment it's running the SEQ and BLM just fine.

Model is TRACOPOWER TCP531

-

If you need, I suggest ordering from Sparkfun et al. Instead I'm working on a different concept using hollow shaft encoders and WS2812 LEDs arranged on a PCB. This should be more flexible in terms of multicolour possibilities, also the PCB routing is much easier!

-

1

1

-

-

I don't see a schematic for the SEQ v4 lite. But one trick I found for the BLM is that Schottky diodes from the base to collector help to turn off transistors faster and can reduce ghosting on the current sink side. Also in my case there are 10k resistors from the base to the emitter to reduce power draw, and to provide a current path if the base is ever in a high impedance state.

-

Wrong topic?!

-

A problem... and a solution.

Testing the BLM the last couple of weeks I was getting intermittent behaviour. Notably the SEQ was having trouble communicating at power on and the miniCore would reset if too many blue LEDs were lit. I think what happened is large spikes were causing the supply to drop out, which might appear as a reset pulse on pin 1. The problem remained if I used different 5V PSUs (switching and linear) and adding extra caps to smooth the rail didn't help. TK. managed to get all of his LEDs lit without any comment, so I can't rule out that it is particular to my build, or is caused by faster switching due to the Schottky diodes that I added. I'm interested to see how others go with their BLMs.

The power situation is not ideal. Running everything connected to the DIN cable means there's quite a lot of cable impedance/inductance and the regulation is far away. Using 5V means there is no headroom for a normal regulator, and as the Quad IIC board uses the same rail to drive the MIDI IO circuit, using a higher voltage here isn't really feasible.

One option is to use the extra case holes to connect a higher (e.g. 9V) DC input, then regulate down from there. A simple regulator could be built in the "muck" area present at the top (but beware that the acrylic spacer sits over the other side of the PCB).

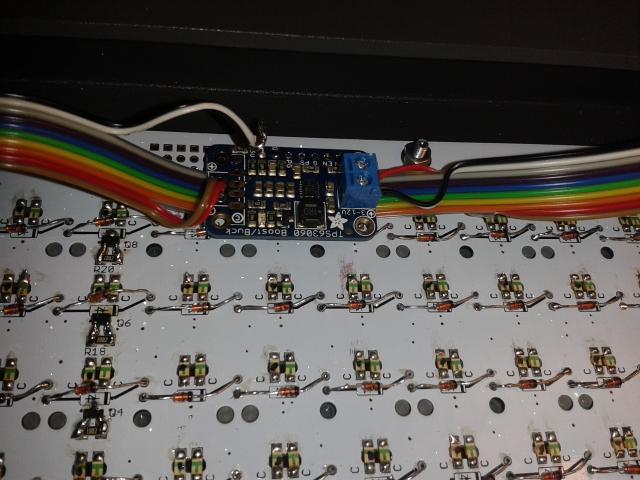

Or, continue to use the 5V line from the Quad IIC board but with a regulator injected in. 5V input means you need a "Buck Boost" converter. I bought an adafruit "Verter" board, which are around $10. I thought the simplest place to put it would be in place of the R1 bridge wire, but the problem is really on the miniCore side. So I cut the 5V and ground lines coming in after the DIN socket. For mounting I used an SIL header in the blank muck area; there are some unused functions on the Verter PCB like enable etc. I only had one terminal socket handy so I soldered directly to the output.

The result is much better: the BLM initialises as soon as the SEQ is ready and there is no problem illuminating all LEDs. The Verter specifies that its normal 5V output is actually 5.2V, which is still fine for the PIC and its analogue inputs. This also helps with the inevitable voltage drop observed when many LEDs are lit.

Happy BLMing!

Someone asked about power draw (also added to the first post):

- Using the Verter, standby voltage and current is 5.2V and about 30-60mA.

- With all LEDs lit (both colours) the draw goes up to 647mA, although this would never be done in normal operation.

- In track mode with all 16x16 blue LEDs lit the draw is 467mA and the voltage drops to 4.72V. I don't really perceive a difference in brightness, but it could only be a good thing! As long as the ADC inputs are scanned relative to the supply voltage you shouldn't lose control at the top end.

-

-

Hello freddy,

this one seems to do the same job at a lower price: https://supr.com/mode-machines/products/cerebelusb-usb and is Adruino based (which may be beter or worse than STM, probably better).

best, Michael

The performance of Arduino-based controllers is generally worse than many of the alternatives e.g. Raspberry Pi etc.Just wondering, why nobody was willing to reply to these questions, yet.

For the port-to-MIDI wiring the problem comes from the grey cable connecting both modules: which pin wires to which pin? That's not 100 % clear from looking at the board schematics. I can guess it, but I prefer to know it.

Also, my question "is it stand-alone or do I need a computer connection always" should be a no brainer for the experienced Discovery user ; -)

So, I welcome your information. Thanks + best, Michael

I haven't tried running the STM32 F4 Core in Host mode with a computer connected or not. The STM32 F1 Core works just fine standalone.

For your wiring question: you have all the info you need in the schematics. As you choose to use a non-standard method (would be very simple with the carrier PCBs) you will have to join the dots yourself.

-

Duophonic keyboard? In keyboard mode, hold two X column buttons to select two tracks e.g. 1&5 (aka G1T1 and G2T1). Track 1 is controlled by the top 8 buttons, track 5 by the bottom. Damn, I'm not sure how the transpose works then!

-

Congrats on the build if all is well!

You need to first burn a virgin PIC with the MIOS bootloader. After you can send it regular MIDI data using MIOS Studio.

The easiest way is with a normal 8-bit Core because it has standard MIDI ports.

The update is possible if you have your SEQ ready to go with the DIN cable and everything, just configure the router page using e.g. USB2->MIDI3 and MIDI3->USB2. Select USB2 as the MIDI in and out on MIOS Studio and you're talking to the Core8!

-

lifetimecycle? (how many hundret thousends or millions/ or self cleaning....)

Lifetime is given as 500k cycles to retain contact resistance (<100mOhm increase) and operating force (+/-30%).

-

Hi Michael,

Here you can find more info and pin assignments:

http://www.ucapps.de/mbhp_core_stm32f4.html

http://www.ucapps.de/mbhp/mbhp_core_stm32f4.pdfYou will have to close the MIDI current loop:

http://www.ucapps.de/mbhp/mbhp_midi_io.pdf

You can see it should have an optocoupler on the input side, and series resistors/pull up on the output side.

-

The last lot of samples cost me $150 to ship... so I have not yet tested the action.

This one has an operating force of 180±50gf and a switch travel of 0.2±0.1mm. So very much like the standard SEQ switches.

-

I will soon be ordering some custom parts and I thought it might be a good opportunity to get some special switches at the same time.

This is an RGB tact switch with a common anode. The key specs are:

Brightness (RGB) 320, 300, 110 mcd, so similar to the LEDs used in the BLM.

Viewing angle: 120 degrees.

Lead spacing: 4.5*6.5mm

Cap dimensions: 7.8*7.8mmPricing is not fixed yet but could be around 2-2.50 USD per piece.

Please indicate any quantities that you would like. It's not a commitment to buy, it just gives me some idea during the order process.

-

-

Hi George,

You want to wire SO (serial output) from the Core to SI (serial input) on the AOUT_NG.

The top row of J19 is:

Vs Vd SO SC RC1

0V, 5V, serial out, serial clock, chip select 1.

J1 on AOUT_NG is:

Vs Vd CS SI SC

0V, 5V, chip select, serial input, serial clock.

You can see how the chip select jumps into the middle and pushes SI and SC over. So wiring up an IDC like I showed is one way around this mismatch. You could still use this cable with the line driver board ignoring the JAOUT header.

-

2*Core8 running MBCV. 2*AOUT_NG for 16 CV. 5V gates come from Core J5 I think.

MIDI out1 to MIDI in2. Should be able to set up a MIDI merge.

-

1

1

-

-

Good to know! I'm obviously not using the line driver boards.

-

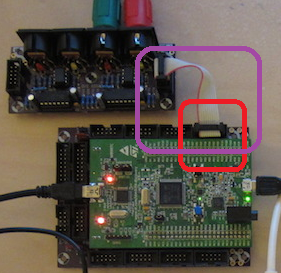

Easiest way to do it quick. Here the black wire is pin 1, brown is pin

56 but the right-most. This cable is 1:1 on the Core, probably simplest to wire the line driver straight and yoga after. The top row relative to the guide nub contains the serial output (SO) and so should connect to the AOUT data header. -

Have you tried connecting the AOUT_NG directly to the Core?

Keep in mind

the non-standard pinning!that the pinning is not 1:1. -

That's really nice of them to give you the circuit diagram!

I had a look too, I think the reset pulse is only generated on power up once the input voltage is stable and the zener diode starts to conduct. So fiddling with U20 is the correct way IMO.

-

Any further thoughts? Is the concept workable/what people want in MIDIbox CV?

I think at this stage it will be a good idea to create several small PCBs, that way the component heights are not so critical and it's more flexible (can even be used in other MIDIbox projects). I've also looked at getting RGB tact switches.

The tricky part is still the OLEDs, I want to get them very close together which is difficult with the breakout boards. More expensive too. Soldering the 0.7mm ribbon is known to be troublesome but I'll try to find a way.

BLM 16x16+X build guide

in MIDIbox BLM

Posted

What an interesting post! If you like I can sell you one of the bugged circuit boards. The potential applications are for floor tiles, doormats, frisbee etc.

The board I was talking about is this one:

http://midiboxshop.bigcartel.com/product/quad-iic_midi-module-board

http://www.midibox-shop.com/quadIIcMIDIR2.html

As you can see, it generates 4x MIDI outs from the IIC buss. Notice the extra circuit is dedicated for the BLM and just optocouples MIDI IN (3) and provides a pullup for MIDI OUT (3). It conveniently has a DIN8 connector right on the PCB. So I guess if you wanted to use your PCB, you would ignore the PIC 16F and connect up J4 on the IIC to J5B on the Core. Or the opto circuit could be built on veroboard. I'm not too sure if it should run at 3V3 or 5V. Maybe try the lower voltage and see if the MIDI transfer is stable. It seems sensible to power the optocoupler at 3V3 as this should (?) levelshift the 5V MIDI IN signal from the BLM. Likewise, any 3V3 MIDI IN signal entering the miniCore should be level shifted up to 5V. Please correct me if I'm wrong!

Just imagine this connector as 0V, 5V (perhaps not connected if you power the BLM separately), and the standard MIDI connections MI+, MI-, MO+ and MO-. Only two connections are "data" that need to connect to the Core, the other two are a pull up for MIDI OUT and a "virtual ground" for MIDI IN. But I admit I'm not well versed in the lingo of MIDI current loops!

I suggest to use a 10 pin ribbon cable and connect the 4*0V and 2*5V to the DIN8 panelmount socket to decrease resistance in the thin wires. These connections are made on the miniCore PCB itself, so no need to add more solder. But if you're like me, sometimes when heating up large ground planes the solder flows a bit thick and bridges a few common pins. That's okay too.