-

Posts

2,524 -

Joined

-

Last visited

-

Days Won

149

Content Type

Profiles

Forums

Blogs

Gallery

Posts posted by latigid on

-

-

You can jury rig a 4x 1k network pretty easily

It might go better on the rear side of the Core?

-

Normally if you can get communication going over USB, the LCD should boot up with either "READY" or a start screen from the application.

- Is your resistor network soldered the right way around?

- How long is the cable for the LCD?

- photos

- photos

-

I'm wondering if the transistor is correctly installed or has a non-standard pinout.

-

- Is the voltage set to the proper value (probably +5V)?

- Is the chip 74HC595 or 74HCT595?

- Did you try swapping the chip?

- Is it a real Discovery board or a cheap clone?

Decent pictures would help in troubleshooting

-

Some other ideas:

- make the track divider very long, so the retrigger occurs after a longer time

- set the gate length to full (glide), wait for the step to play then remove the step (or mute the track?). Perhaps the note off event will not be sent in this case.

-

Did you try fiddling with the Glide trig layer?

-

^^ these are very nice troubleshooting tips @gerald.wert!

A bit of info can be gleaned from the following MIOS code:

a "stab in the dark" test could be to load the bootloader hex (through MIOS Studio, not using the boothold mode) and change for one of the following LCD types:

MIOS32_LCD_TYPE_CLCD = 0x00,

MIOS32_LCD_TYPE_CLCD_DOG = 0x01,

MIOS32_LCD_TYPE_CLCD_PP = 0x02,only the 0x00, 0x01 or 0x02 are needed.

QuoteLCD Type: applications which are compiled with the "universal" LCD driver can handle various character/graphical LCD types and display dimensions.

It's recommended to store these parameters of your MIDIbox in the bootloader info range.

Following commands are available:lcd_types lists all available LCD types and their appr. number set lcd_type the LCD type number (enter "lcd_types" to get a list of available types) set lcd_num_x number of LCDs in X direction set lcd_num_y number of LCDs in Y direction set lcd_width width of a single LCD (*) set lcd_height height of a single LCD (*) store(*) CLCDs: number of characters, GLCD: number of pixels

Example: a single HD44780 based 2x20 character LCD is connected to your MIDIbox (default)

Enter:lcd_type CLCD lcd_num_x 1 lcd_num_y 1 lcd_width 20 lcd_height 2 storeExample2: two HD44780 based 2x40 character LCDs are connected to your MIDIbox

Enter:lcd_type CLCD lcd_num_x 2 lcd_num_y 1 lcd_width 40 lcd_height 2 storeExample3: five SSD1306 based 128x64 OLEDs are connected to your MIDIbox in vertical direction

Enter:lcd_type GLCD_SSD1306 lcd_num_x 1 lcd_num_y 5 lcd_width 128 lcd_height 64 storePlease note: some applications (like MIDIbox SEQ V4) could overrule the predefined parameters if they can't handle smaller (or larger) LCD sizes.

Please note also: some applications could have been released with a different LCD driver (MIOS32_LCD != "universal") which don't consider these parameters. It's up to the developer to document this limitation. -

You might try some of the other LCD configs, though I couldn't say what one would be better.

For the SD card, one way is to edit the file with a text editor on your computer and upload it using the file browser. Normally uploads go okay, but downloads hardly ever work for me.

-

Of course, I asked incessantly if they could add switches, but because of the design that isn't possible. The workaround is to use individual metal touch sensors, which is a bit different but is quite easy to get used to I think.

-

Yep, I've tried jam mode too and liked it quite a lot! It's my hope that the 16 selection buttons can be used in a mode to jump to different sections of a song for freeform restyling.

-

From me :) (custom order of 1000 parts was the minimum to test).

-

Here are the buttons and encoders

and the 'ELO board:

Sorry for the long-winded explanations. The shine through effect will be much better with clear Waldorf knobs, but I don't have any on hand at the moment.

Most of the discrete SMT is for touch sensors (here they are single metal plates), so if you just want the displays + illuminated encoders, the assembly is very straightforward -- shift register chain and some 2*5 headers.

@Hawkeye and I are slowly getting the "standard" Programma together, but of course these are good to go for other usecases.

Best,

Andy -

While not LED rings, I have some 4*4 encoder boards that use WS2812 LEDs. The simplest MIOS implementation fixes the colour (as RGB or hsv (better)) and uses the level/brightness to indicate the CC value from 0-127.

I have two types available; a simple one with just encoders, and a more complex one that uses the 45 degree displays (as part of MBProgramma v2). For buttons, there's a 4*4 matrix using the same programmable LEDs and Sparkfun button pads.

Feel free to shoot a PM if you're interested in getting some or you want more info.

Best

Andy -

-

CN1 is the miniUSB and is used to flash the bootloader via ST-LINK. It also supplies power to the target.

CN5 is the microUSB for uploading MIOS apps. Its "Vbus" is not connected to the +5V required to supply the MCU, so you need a jumper cable or a Core PCB.

The issue with the older firmware is an absence of a USB connection in CN1 would hold the main MCU in reset. This was rectified in the later firmware update for ST-LINK v2.

-

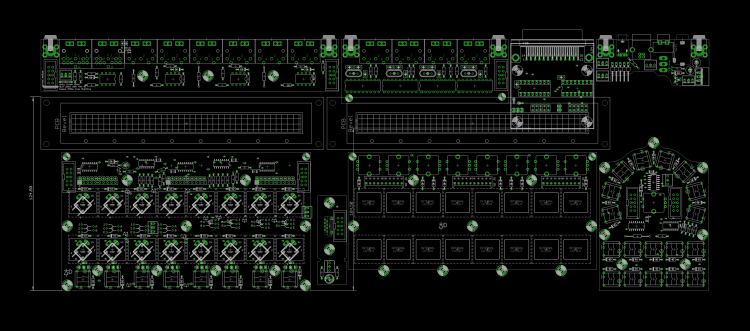

I decided to re-spin the boards:

- a bit more compact; the idea is to use the panel mount screws for fixing, but there was room for one standoff. If needed, the holes (~3.3mm) in the connector can be utilised instead of soldering down the metal tabs

- layout improved -- single layer with power/plane on the other side. No vias for the signal lines.

- +5V is connected through a jumper on both ends, so one could add a power supply if required or disconnect if the cable has too much voltage drop.

- JAOUT is there, but it would be better IMO to use either a special ribbon cable on the 2*5 or just ensure the AOUT boards have a 1:1 compatible IDC.

- Alternative connection on a 26-way IDC header. This might be useful if the DB-25 is too chunky or needs a free-hanging connector like this.

-

I route up my boards using separate traces for RC1 and RC2, and I split SC into SC_DOUT and SC_DIN if it's practical.

Hopefully it works to tie RC1 and RC2 together where it's needed. IMO it's the "least critical" signal of the SRIO chain as it just tells the shift register when to transfer the 8 bits from storage to the outputs in the case of DOUT, or when to scan the inputs for DIN.

-

If you look at the old PIC8 Core, there was only a single RC line. Now they are separated (different MCU pins and also buffered), but RC1 and RC2 send latch pulses at the same time. I.e. for the moment (and foreseeable future) there's no practical difference between them. This is not the case for other SPI ports, like J19 or J16, where the RCs are "chip selects" for separate peripherals.

When Wilba did his SEQ PCB, he simply bussed the two RCs together. My guess is running data busses in parallel is more important when you have chains of DIN/DOUT separated over multiple PCBs, rather than BLMs etc. on a single PCB. Still, the best practice is apparently to split both RC and SC (!) and run whole chains of DIN/DOUT. The SC on the output header is best sourced from the longer chain (either DIN or DOUT):

More to the point of your build, RC1 should be routed with the DOUT side, and RC2 with the DIN side. You've done it the other way around. I don't have any DIOMATRIX modules, but from the schem TK. is not following his own guidelines

. Because RC2 isn't connected on DIOMATRIX, and your PCBs correctly spilt them, then the result is no connection for the RC2 line on your PCB.

. Because RC2 isn't connected on DIOMATRIX, and your PCBs correctly spilt them, then the result is no connection for the RC2 line on your PCB.

I think you can solve this by bridging RC1 -> RC2 on one of the headers e.g. on the output of DIOMATRIX or the input of your board.

-

Is the issue still with the line driver/receiver? Can you get the AOUT to work when using _NG with data passing through the driver/receiver?

Often my AOUT_NG needs a reset; it can be that the PSU doesn't stabilise fast enough to receive an init command correctly. This is easiest done by changing the AOUT type back and forth in the CV setup menu (e.g. AOUT_NG -> _LC -> _NG).

-

How to do illuminated encoders (pots) if you're Waldorf:

Quite classy, and uses an interesting lens to shine the light upwards.

They've even got the bipolar red/green going.

-

12 minutes ago, tago said:

With my current design i'd need 4* DINX4 and 4* DOUTX4 when using direct connections between Btns/LEDs and SRs. For potentiometers i'd have an AINSER64. According to the docs double than that should be possible, but is such a large number of SRs going to negatively affect the MIOS32/Core32 performance?

This is easy to test, just increase the number of shift registers defined in the NGC (max 32 I think), even if you have fewer in your chain. Now connect some hardware and see if you notice the latency. If you do, decrease the number of SRs until you're happy.

QuoteIs it possible to leave some LEDs out (eg per row) in a matrix?

Yes.

QuoteCould you explain "multiple matrices based on smaller sections" any further?

Instead of an 8*8 matrix, define two different ones, or however many you require based on the panel layout. You don't have to fill every position.

QuoteI'm really not sure if matrix wiring is going to be too tricky/messy with frontpanel perfboards in the end. I've to make the (large) frontpanel pcb out of smaller ones. I assume for matrices i'll need some busses on these perfboards. But how will they fit in a space saving manner on a 2,54mm grid? Unfortunately i couldn't find photos of similar projects on the web to see how others approach all this.

Draw your panel, divide the thing into sections. Perfboard/stripboard is useful if you have regular 0.1" spacing, also consider the different heights of components and group those of a similar/adjustable height (e.g. LEDs are versatile).

I suggest that you go for the direct wiring route. It's a much more linear way of solving the problem, and you're not constrained by fixed geometries. It's easy to address each element and to fix mistakes.

-

Hi Johan,

Thanks!

As part of the design process the jogwheel is now just a normal encoder (with a push switch). The rationale for leaving the jog/shuttle off:

- availability isn't great, though could come directly from ALPS

- size is pretty massive

-

additional software handling is required to scan the absolute position encoder and the spring-loaded sides

- as this would likely fall to TK., it's extra coding effort that he wouldn't find useful himself, he's a really busy guy!

-

currently there aren't any applicable parameters to match functions on the SEQ

- I suggested a progressively accelerated increment/decrement, but there wasn't much buzz around the idea

Hopefully the normal DK-38 with a push button, along with acceleratable GP encoders is okay (c.f. Machinedrum/elektron stuff). If someone wants to make a PCB for the jog/shuttle and code in the extras, then it's totally doable with modular PCBs!

-

1

1

-

This is awesome! I love the fit-for-purpose design, and the self-routed PCBs are really hardcore. Do we get to see/hear it in action?

-

Getting there :-)

The modular PCBs are basically done; the top row would be underneath the OLEDs. I was looking at a through hole microSD card on the front, but I'm changing the Core so it will move to the back and turn into the common 3M full sized one. Have to figure out a different solution for the beat LED, which TK. insisted on :-). It might be that the Line Driver can be squashed a bit, but there should be plenty of room for everything, even AOUT/DOUT boards with a breakout on DB-25 (or 3.5mm/1/4" sockets) instead if you wanted.

Because the PCBs are modular, you could move the jogwheel into the centre. TK. would say that this disconnects the displays, especially when there's information that flows onto the second OLED. But if you prefer a bit more symmetry then why not? :-)

For sure, I'm a DAW-less guy, so this is gonna be the heart of my setup too.

Best,

Andy-

1

1

-

RGB hue sweep

in MIDIbox NG

Posted

The datastream for WS2812 is serial and runs separately to J8/9, so matrix events don't make sense. Instead, each LED needs its own EVENT_RGBLED. The current _NG implementation can either change the hue (colour) or the value (brightness) when dimmed=1.

Let me know if you want some PCBs and/or encoders.

Best,

Andy