Search the Community

Showing results for tags 'matrix'.

-

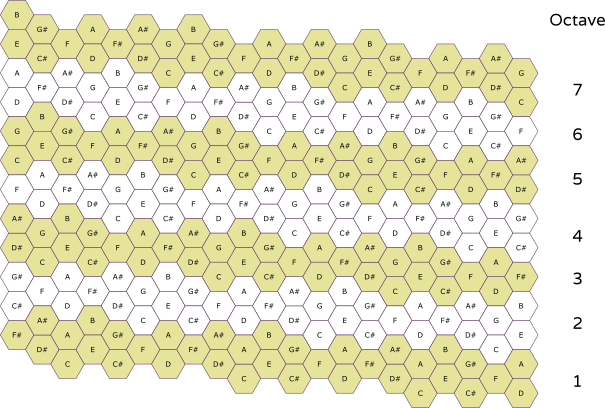

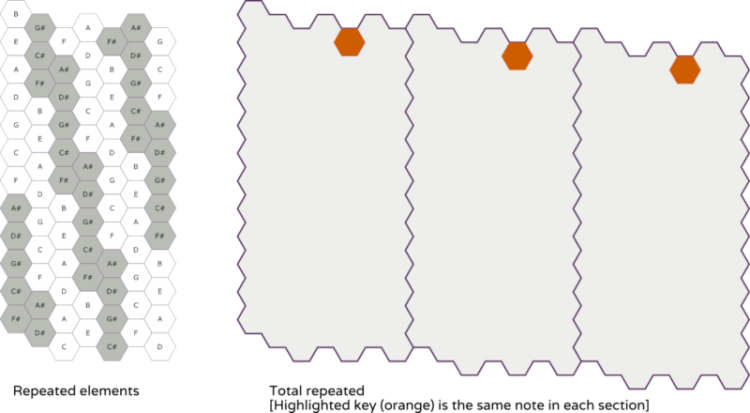

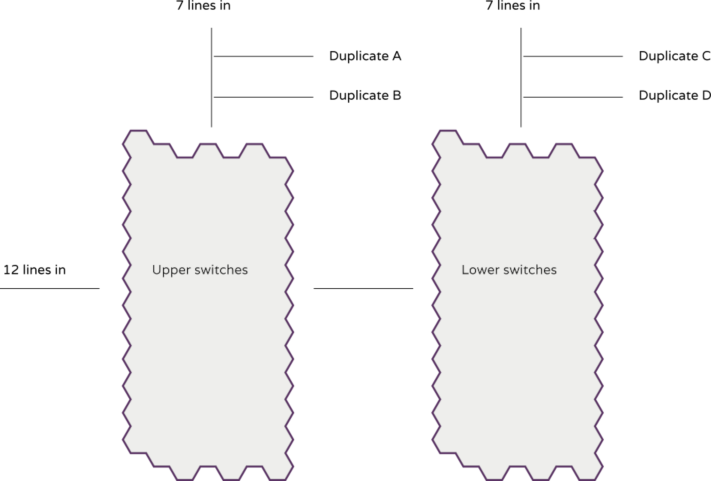

I am working on a harmonic table midi keyboard inspired by http://wiki.lvl1.org/Isomorphic_Keyboard This will be a grid of 21x12 keys with two switches per key. Two sets of matrix switches, one upper PCB and one Lower PCB to.determine velocity. I was concerned about scanning two large matrices, but the keys repeat along its length, By duplicating the lines in, the 21x12 matrix can be reduced to 7x12. This should hopefully reduce the total matrix scanning time with only sacrificing the option to designate keyboard sections to different channels. Are there any problems to this approach? Regarding resistors, do I need any on the lines in/out and if so should they be before the line split or after? Thank you for the help.

-

Hi everybody, Sit down ... Take a deep breath ... Close your eyes ... Now your mind is free ... Start dreaming about your perfect MIDI Router ... Imagine its IO count, features, shape / case, its behaviour and menu / screen functions... Leave aside any technical limitations, just imagine it ... Could you take a few minutes to describe it, please? Best regards Bruno Yes, latency is important in particular when routing is chain of MIDI equipment. Labels for direct viewing is something obliged. Routing Presets of course... Easy and fast ui port/channel routing access! --> a good USER INTERFACE Optional 'panic' function for lost note-off or high sustain during a port/channel switching. --> panic option for quiet switch Yes definitively! We can imagine some dedicated sysex commands... I love this idea too. We can imagine more than that, more than label IO and device name, with the use of the SD card we can try to get a library of CC, drum mapping names too. That's perfect!

-

Hi, in the pdf on the Wilba frontpanel button/LED matrix, the dual-color GPx LEDs are said to be hardcoded into the firmware. But in the said pdf the information on how to wire them is confusing. In the schematic the dual-color LEDs are wired to pins D4-D7, but in the chart next to the schematic they are wired to pins D3-D0. The question is: which version in the linked pdf – schematic or chart – is the one that I should use if I want to make a DIY frontpanel with DIO matrix?

-

Need some technical advice about a question: May encoders be managed in a switch matrix design? see http://wiki.midibox.org/doku.php?id=switch#connection it may allow to manage large encoders numbers by having less DIN/DOUTs inputs outputs Bests, JK

-

Has anybody built a BLM with bidirectional two lead duocolor LEDs, where the two colors can be adressed by reversing the polarity? How would the scan circuit have to be designed in order to work with the standard midibox solutions? Of course, compared with the scalar board, the resistor-transistor arrangement of IC2 could be placed next to IC3 and another 74HC595 next to IC2. But then the scan algorythm would also have to scan each color sequentially. Why am I looking for such a solution? I evaluated the the switch of choice for my Synth project: For my needs, I only have single color buttons (yellow). But this button could also be interesting for BLM applications where duocolor would be needed (RGB is available as well). I am working on a versatile matrix PCB solution for my synth project, where single rows of a matrix can be cut to the desired length and the LEDs can be adressed individually via solder jumpers. These smaller boards can be bought much cheaper in small quantities than the propriatary matrix boards and in my case serve different needs.

-

Hello Folks, Due to oveproduction I am offering 2 of the following panels: Monome 128 Panel Aluminium, 6mm thick Raw finish, pleas brush or paint yourself (if you don't want to do it yourself I may brush it and throw some transparent coating on it I got laying around for a bit extra) No holes or drillings Original measurements from Monome plans Lasermanufactured Please note these are kind of heavy, so shipping to outter Germany might be costy. Please PM if you are interested. Here's a picture. I didn't have acces to a better camera sadly.