-

Posts

2,524 -

Joined

-

Last visited

-

Days Won

149

Content Type

Profiles

Forums

Blogs

Gallery

Everything posted by latigid on

-

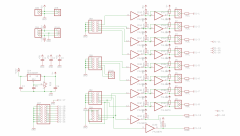

It might involve specially programmed 16F88s. Note that the Quad IIC has a circuit-level implementation (EDIT pins 12 and 13 as shown on the schem.) for addressing the IICs (MIDI OUTs), so you might need a custom PCB for more outputs.

-

USB MIDI perhaps?

-

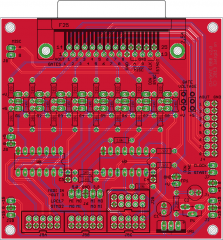

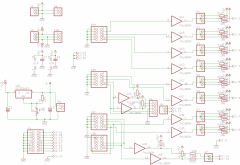

I think that this can be more efficient with only two 7407 chips and a switchable pull-up voltage instead. Working on this now.

-

If you can't beat 'em, join 'em. Following a discovery that the I am working on a revised design based on SN7407 level shifters. (If you want a board from the the buffers work as expected, please PM me for details.) Simple enough circuit but I have several questions. First off: any problem with cascading the buffers this way? The idea is to have a switchable output between +5 (also serving as Vdd for the ICs) and an adjustable voltage which is derived from a low-dropout regulator (say 12 V or higher). It is more simple to route when the output of the first buffer connects to the input of the second, but would it be better to tie the inputs of both buffers together instead? What should the handling of MIDI IN 3 and MIDI OUT 3 be? Presumably MIDI IN 3 should go through an optocoupler with a 3.3 V pull-up on the Core side: http://ucapps.de/mbhp/mbhp_core_lpc17_midi3_midi4_extension.pdf Hence, no level shifting is necessary I think. But for MIDI OUT 3? From the Quad-IIC schematic it is not clear whether the signal needs to be level-shifted. Will a 3.3 V output be compatible with the 8-bit core of the BLM? In this case, MIDI OUT 3 is level shifted: http://ucapps.de/mbhp/mbhp_core_lpc17_output_buffers.pdf For these two, it isn't: http://ucapps.de/mbhp/mbhp_core_stm32_midi3_extension.pdf http://ucapps.de/midibox_blm/blm_connector_mbseq.pdf There is a 3.3 V pull-up for the LPC core: http://ucapps.de/mbhp/mbhp_core_lpc17_midi3_midi4_extension.pdf Even though I will not use the LPC core, I plan to make it compatible with both for the greatest flexibility. Some clarification would be welcome. Cheers,

-

I'm not really familiar with the LTC module sorry, and I mis-spoke when I said MIDI thru before, of course you would be just duplicating the ports. It seems as if the serial functionality of the LTC module is not really useful any more. As far as I know you can use the buffer/level shifter IC to do this duplication. Hope that helps,

-

This is effectively like a MIDI thru port; using the IIC modules will give you the benefits of more channels, less configuration required, lower latency etc. How many do you require? Are you aware of the Quad-IIC board available at SmashTV's shop?

-

No worries, it's outmoded hardware anyway :tongue: Hopefully I can come up with something to work with my board layout.

-

Thanks TK, but I seem to be getting conflicting advice. What does the setting "J5_ENABLED 2" actually do then?

-

I have 10k resistor networks connected to each gate and DIN sync, and the common pin is showing +5V. In the HW file I have J5_ENABLED 2 But I only see around 3.7 V for each gate. Any suggestions?

-

Glad that you're okay! It's hard to imagine so much damage being done in so little time... Wishing you the best, Andy

-

-

-

I think that we're over the 8 boards that I have available, but there's always the possibility that people back out etc. I am currently waiting on a bit of advice with regard to level-shifting the gates from the STM32 core, I'd rather not fry my pins :) I'm happy to organise another run if there is demand for one.

-

My plan, unless anybody tells me otherwise (please do if this sounds stupid) is to solder 220 ohm resistor arrays to the core32 pcb in order to achieve the +5 V signals. Will this work with all outputs, including the 8 gates, MIDI I/O 3 and DIN sync start/clock? Or do these pins also require setting to open drain mode? Thanks, EDIT: or is 1k or 10k more appropriate? There is a +5 V rail running very close to J5A/B/C

-

And dare I ask, in what situations would one use open drain mode?

-

Just because I have things soldered already :smile: I was hoping for switchable gain between +5 V and something arbitrary like +12 V, but like you say I can just fiddle with the feedback resistors to tailor the gain level. Many thanks and greetings, Andy Edit: the gates should be enabled, but not in open drain mode, correct? J5_ENABLED 1

-

Yes, this makes sense. Apologies, I did see this note but wanted to avoid the 74HC541 because I am already buffering the gates with my break out board: I wonder what is the best way to proceed while still using the board that I have. Do you think the buffers here would offer sufficient protection to simply use pull up resistors like I thought? Or would it be better to make use of a trimmer pot to have more control over the gain?

-

This might be a simple question but I don't see it documented anywhere. I want to use the +5 V gates, do I simply connect the gate output to Vdd via a 220 ohm resistor? From the Core 32 schematic these are normally set for 3.3V, correct?

-

After a few chores I managed to make all of the connections to the SEQ today. Everything fits, although I did have to shave down the SIL headers for the 15 mm clearance below the AOUT_NG. I'm off for a week tomorrow, so you'll have to "watch this space" :)

-

Okay, we can use this as an unofficial waiting list. I would like to test and document the boards first though. Just finding the time as usual... but Thursday is a holiday for me!

-

Badass, great job. National colours too :thumbsup:

-

Is it possible to map an extra parameter on the y axis? :rolleyes: