-

Posts

1,184 -

Joined

-

Last visited

-

Days Won

30

Content Type

Profiles

Forums

Blogs

Gallery

Everything posted by Altitude

-

New eurorack modules from midiphy - preview

Altitude commented on Hawkeye's gallery image in Members Gallery

-

-

dipCoreF4 and dipBoardF4, a compact Core.

Altitude replied to Antichambre's topic in Design Concepts

My new euro module: https://michigansynthworks.com/p/sy0-5-analog-drum-module-coming-fall-2018 -

dipCoreF4 and dipBoardF4, a compact Core.

Altitude replied to Antichambre's topic in Design Concepts

-

dipCoreF4 and dipBoardF4, a compact Core.

Altitude replied to Antichambre's topic in Design Concepts

Im with Andy, I always make the isolation as BIG as practical. If you have to pack it in, you have to pack it in but only do so where absolutely needed. You can pour different polygons with different isolation on the same net too if you need it tight one place and not another. Every time i've gotten bad boards from OSHpark (3 times this has happened) it was because there was a super tight/dense space and the etching didnt get all the copper. They are probably way more sensitive to this than other fabs since they do big ass boards with many designs and i bet its easy to have issues etching something that size. I think it boils down to getting a handle of what the fab says they can do and what they can actually do reliably. I had problems with Seeed with my first order there and never went back, the etching was rough, the soldermask was poorly registered, just blah everywhere. JLC i'll use for big stuff since their pricing is good but small stuff they have issues with clean screens even at their minimum text size spec. PCBway has nice machines but they take a maximum X size of 110ish mm so big stuff gets pricey there too, They cant do small text like OSHpark can on that machine. So it's a mixed bag always where ever you go. I go through a thousand boards a year and have yet to see a etching fault on any of the Chinese fabs which is why I dont use OSHpark anymore, it was a convenient service 5 years ago but the prototype biz in china has exploded and you can do much better for much less time and money. Standard turn around for protos is 2 days at any place out there -

dipCoreF4 and dipBoardF4, a compact Core.

Altitude replied to Antichambre's topic in Design Concepts

works for me :) -

dipCoreF4 and dipBoardF4, a compact Core.

Altitude replied to Antichambre's topic in Design Concepts

Oh, in for sure. I have clamshells for F405s to flash the bootloaders too -

Oh this is great. This was something I wanted to add along with the new aout im working on based on TI DAC8568 (8 channel part, same as used in O_C, Yarns, others)

-

LoopA V2 Introduction, Features & Support Thread

Altitude replied to Hawkeye's topic in MIDIbox User Projects

awesome to see this done! -

I've built a bit of experience with this and that euro module in the last year or so and been working on my own Aout in parallel and found it's pretty unsuitable in it's present state. Namely: The bipolar circuit is referenced to the power rails and in a full euro cab, that is a VERY bad idea, massive noise ingress is the result making it useavle. Removing that part of the circuit brings it back to very decent levels but 0-10V isnt terribly useful in euro. Also, scaling the DAC outputs with a trimmer is a bit crude, per volt adjustments would be MUCH better (like in Ornament_crime or Yarns). My idea is to keep the MAX525s since they are available and decent parts and serial addressed but switch the analog output stage to that of Yarns or O_C (-3 to 7V or -3 to 6V outputs respectively) and port over the code for the calibration of those devices (whichever is easier). The hardware side is covered but I really need someone who can code to deal with that end of it. O_C is teensy 3.2 base but Yarns is STMF405 which should be very close to the current core code base.. I'll provide hardware to work with for any takers

-

Possible new case option, without needing Heidenreich group buys

Altitude replied to julianf's topic in MIDIbox SEQ

Moog case is a no go if you want stuff on the back, it has fins inside that cause problems. Ill post some pics shortly -

fine looking device. Out of curiosity, how did you do the laser cut button caps?

-

i've done it both ways and I dont see any difference one way or another. If I had to do it again, I'd use the 7809, cheaper and smaller. One thing I'd recommend (unrelated to this question): DONT use the E series recoms, they are super cheap for a reason and not well suited for audio applications, Output noise is unacceptably high

-

It would be cool if they could shrink it down to SID size, those are machine stuffed anyway so no reason not to go to a TAG programming header, 0402 passive, small as possible everything else (underneath?)

-

payment requests sent. Here is the BOM https://docs.google.com/spreadsheets/d/1w-VEWmPBQucrhK-vZdvH8pU_xwDvS5GS1VtrLofj800/edit?usp=sharing

-

I just stuck a darkly tinted window, it obscures the depth.. There is no way to go in front of the PCB, it will interfere with the tacts

-

i'll PM ppl for the ones I have, $5 a pop. I'll post an OSHpark project later..

-

I think that there is something else pulling it down, I run mine on USB power all the time when I'm flashing it, check resistance between +5 and gnd and +3.3 and ground

-

There may be current limiting stuff on the discovery board too

-

no, just havent had time to deal with this..

-

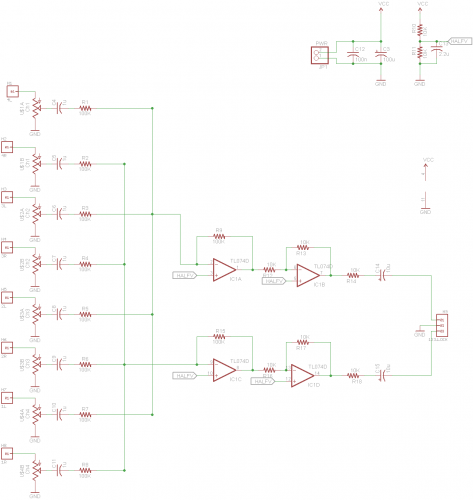

I like the feedback as well but its REALLY cumbersome to use the MB6582 with a 8 channel snake out the back. I used a single supply with TL074 running off the 9V

-

Correct. There are 2 ways to wire this in, pre the jack which will just mirror what's coming out of the channel or post jack by puling the 10ks in the passive mixer so the SID pair is removed from the mix when you plug something in

-

Mouser stocks Vishay OLEDS which are rebadged raystars..

-

So after years one planning to do this, I finally got around to it. Here are the results: Simple TL074 based mixer with stereo pots for each channel that fits to the existing holes. I've got a handful of boards if anyone would like one and then I'll post a OSHpark link so anyone can get them any time. Boards: https://oshpark.com/projects/iEI4Yrhq BOM https://docs.google.com/spreadsheets/d/1w-VEWmPBQucrhK-vZdvH8pU_xwDvS5GS1VtrLofj800/edit?usp=sharing