Leaderboard

Popular Content

Showing content with the highest reputation since 12/04/2021 in all areas

-

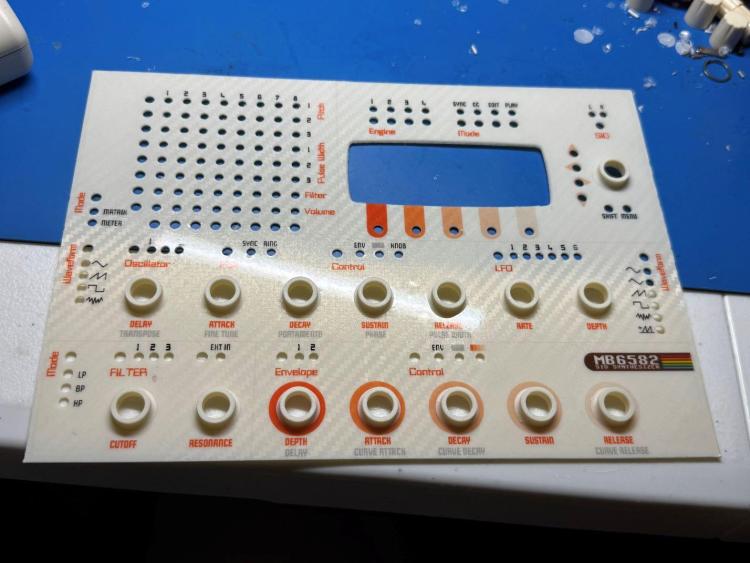

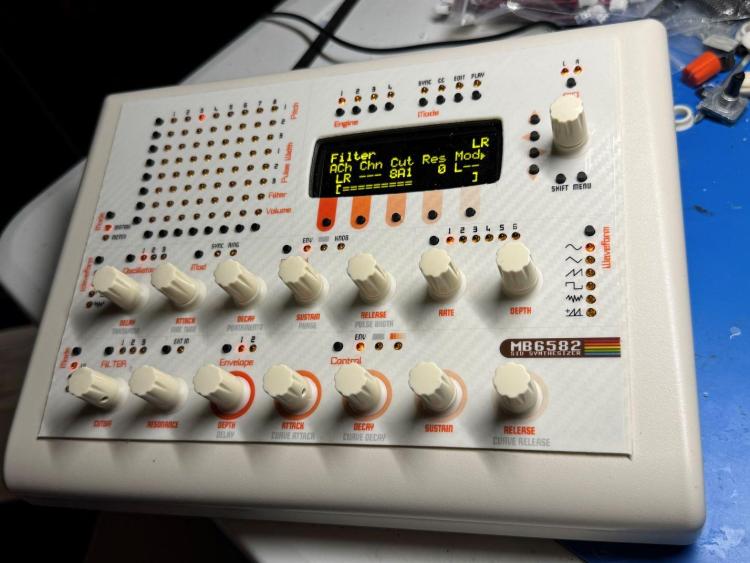

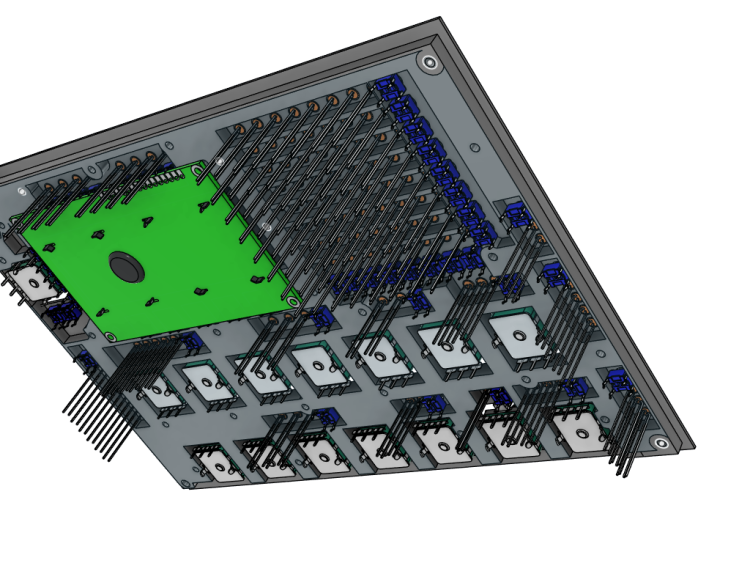

Hey everyone, just wanted to share my latest build since I'm sure there are some 3D printing enthusiasts here like myself. I bought the parts for an MB6582 about 5 years ago, if you remember Meeblip was selling those 8580 SID chips and I picked up 8 of them, and then put everything into a box in a closet . 3D printing has come a very long way since the original MB6582 was created by Wilba. I read that the JB Weld solution may or may not be holding up great after all this time. Also, I wanted to use a Newhaven OLED which is much thinner than the original LCD. I thought there must be a solution to lower the gap distance so why not create some type of spacer for between the front panel and the PCB? I designed all parts in Fusion360. The PCB screws directly into the spacer using M2.5 nuts/screws and plastic screws. The top of it has a flange that rests in the panel groove for the PT-10. Total spacer height is 5.7mm which is the height of the base of the encoders. The front panel is another 1.25mm. Everything is printed out of ASA, which is very strong and heat resistant. I designed the panel graphics in Inkscape and printed on translucent vinyl. I used Davies knobs with small printed skirts to cover up the threads of the encoders since they were exposed. I do not have a vinyl autocutter but I do have an exacto and lots of patience Overall tried going with a 80s beige computer look. A build plate for my printer created the carbon fiber effect on the panel. I'm happy to share the 3D files if anyone could use them.3 points

-

I read a lot of guides. Successfully compiled ASM code. The OLED display works well with an 8bit driver. If anyone needs the firmware, here is: setup_sammich_sid_8bit.hex3 points

-

Hey man. It's actually an FR4-Standard PCB. Non aluminium. But seems pretty robust anyway.2 points

-

2 points

-

2 points

-

Hello how much will cost the mb6582? and also If you plan to build a sammichFM let me know1 point

-

1 point

-

Apologies everyone I just saw these messages. I will make a note of gathering the files tonight and uploading them to the appropriate section here (Thanks Smithy). Thanks everyone for the kind words :)1 point

-

Prompted by a message from freddy, I've attached the project files below. They contain the source and the binaries for the bootloader and the main code. 1.05 is the latest version - there was a fix in the bootloader and the main code. I included some memory in the final hardware design but never got around to doing anything useful with it. I had plans to save one or more demo tunes as MIDI files and perhaps save some settings as profiles for different scenarios - my interests had moved on before that happened. You can find more project info at https://web.archive.org/web/20210206041027/http://www.grapevyne.com/pic.projects/ - the documentation links are all active so you can download the magazine articles and also my original source for the articles (a few errors crept into the magazine article during editing). mistralXG project files.zip mistralBoot.zip1 point

-

To use Studio on newer Ubuntu Desktops you need to install the old libwebkit2gtk-4.0.so.37. To do so create a sources.list file for apt containing the following line: deb http://gb.archive.ubuntu.com/ubuntu jammy main And install the lib. sudo apt update sudo apt install libwebkit2gtk-4.0-dev After this delete the sources.list file. More infos on https://www.weigu.lu/music/midibox_hp_2x2/index.html1 point

-

Reflowed the ttasnsistors on the top side and now I am back to 12 LEDs on. I'm assuming the LEDs shouldn't be on, but otherwise that feels like an improvement as it means I get mattias switch events for 12 of 16. I'm also getting events for depresses on the right 4 encoders although they seem a bit random in the actual event details. I've also replaced IC2, IC3 and T3 based on advice from ChatGPT but that made no difference.1 point

-

This looks amazing! With some of the older chips like vintage vca, filter or delay chips you really have to be careful regarding heat and also (or even more so) static discharge. Nowadays with most ics these issues have long been solved by modern manufacturing processes and built in safety measures. I had to lear the hard way that this is not the case with chips from the 80s... So the heatsink is probably a good idea, as would be any way to allow for some airflow. On the other hand, i have removed the fans from some of my gear with no issues at all, as commercial units have to consider every worst case scenario (crowded rack in hot environment). So if you know how you use your gear you can get away with things that could not be allowed for every scenario.1 point

-

Hi Niles, I still have original mb6582 encoders, bulk ordered and sent by Wilba. Working perfectly! Would you like some? Best1 point

-

1 point

-

1 point

-

i made a passive design, since the fan which came from mouser, was dead from the beginning... since it is a 6582, it was not going very hot anyway... but i drilled Holes into the pcb under the SID-Sockets, and cut aways some plastic from the socket too. i too drilled some holes in the plastic body under the Main-PCB too, the backside off the SID should be enough to get rid off the hot air...1 point

-

1 point

-

Thank's for the tip! What I'm looking for is either the fpd file which fits the Heidenreich case or maybe a ready made panel. The fpd file I found in the Wiki seems to be not specifically made for the Heidenreich case. I prever a fpd file which is proven to fit into the Heidenreich case before trying to adapt Wilbas files to the case.1 point

-

Just a small necro-bump :-) …by now we are roughly 150 people over there with some occasional chatting going on. Feel free to drop by!1 point

-

Hi all , Was wondering about opening a KiCAD Section in the wiki? For tutorials , midibox libs etc... where should i put it? regards, JK Edit : A Frontpanel designer section could be useful too ?That's a soft that i think most of us use? Maybe create a "Softwares" Section?1 point

-

1 point

-

the ssd1306 oleds i received where 5V tolerant... the ws2812b is also in a range from 3.3-5.3V, dout modules also needs 5V... so your reichelt psu should do the job, and you could power them directly from the psu... but i guess you power them with the ribbon cables from your core... i dont know what Core you will use? if you use the WCORE from midiphy, then you may ran into some problems when using a external 5V PSU, see this topic: https://forum.midiphy.com/d/151-wcore-non-usb-powerd-but-still-use-as-usb-device/5 also if you are unlucky you will get walking lines on your SSD1306 screens... then it best it would to buffer each D0 D1 Clock... Pins, which are done for example in this module: http://wiki.midibox.org/doku.php?id=displaydriver-smd a plus is then you can then use more then 8 screens!1 point

-

1 point

-

@ Faderboard 1 & 2 Mounting holes labeling not necessery again. rest is ok. you may could label + and - beside the 2x5 shroudet Pinheaders, so there is no chance someone reverse it in a way... in generell... normally the Nose- says all, but someone could crimp the cable incorrect... so if he controll measure, this is a good hint then for him.1 point

-

@ pusbutton: the LEDs in the shematic are REVERSED for example look into: http://ucapps.de/mbhp/mbhp_doutx4_32leds.pdf but in the board itself the Silkscreen for the Diode is painted correct - so if somebody just solder the PCB without looking into the Shematic - all is good, when someone look into the shematic he may be confused a bit. what type off Switch are using here > type it on the silkscreen - like you did on the Potentiometerboard. because: i see in the footprint its a le mec > then there are different types, with different Switch contacts - like you see here: 5GTH9 + 5ETH9 will work, while 5GTH9 with inbuilt LED will not work off course... i for me find the correct switch matching to your PCBs Footprint-Pinout - a bit hard... so label the type.... the rest off the PCB looks ok.1 point

-

@Hawkeye I have never seen those tutorials before! don't know how I missed that, there is a wealth of info there. Following the tutorial the transpose works, under the scheme laid out in the tutorial. I will try the Root method next and report back. Thanks!1 point

-

at RGB-Leds > i dont know, how many you will use? which coremodule you will use? is it eurorackbased > and eurorack powerd? Which RGB-LED you will use - and what is the Voltage it needs? and so on.... i looked into your files.... some notices: @BP: dont connect the mountingholes to ground, or any other potential, best would be to make a keep out-area (sperrfläche) arround it, like i did for example here: http://wiki.midibox.org/lib/exe/fetch.php?w=600&tok=f96292&media=phatline:daw-btn-3d-b.jpg since you can plastic and/or metall standoffs to mount that pcb to the panel, you would need at least 6mm or more keepout-area.... background: you want to avoid groundloops over the frontpanel, and the risk of a electrical shock is less.... The LEDs in the diagram are connected false, the tip off the arrow should always be connected to the ground. (you should turn them 180°) which buttons do you want to use? please check the pinout off them... for me it happend that i did not connect the correct pins, so double check this.... why you made those cuts on the 4 corners? its better to make them rectangular - background: if you panelize the pcb, you have to draw a V-Grove line, the machine can only Grove in 90°, the idea, is to put 2 off this boards on one 100x100 PCB so you can save money on FAB.... way more oversight you have if you use a Groundsymbol... instead off paint Lines to a ground inside your shematic... look into "control" to see what i mean...also it makes it easyier to work with groundplanes, since this needs a NET... @Control: please open this file:Control.zip the same like above, and, you dont need that vias next to PIN 2 off the switches > Pin 2 is a via itself.... - same for Pin 1 off P2, the Problem it did not fill without your Vias: because you dont used a Ground-Net.... Pin1 - which is labeld as VDD (+) was connect to all your buttons and the pot (which is a Encoder)... normaly we connect them to ground..... VSS is ground.... so i exchanged the whole thing.... i dont know iff this is then still correct in your big picture- wiring diagram.... how ever thats the way i would make it - at least iff the Pin-Labels off the IDC Connectors are right... you should put the 4 mounting holes in the shematic, so you dont loose them when updating the PCB Also dont label your Encoder with Pot or RV >>> this is not a Potentiometer... that confused me until i realized this is a Encoder.... also the google-Drive files are a bit corrupt - the footprints where not assigned to the Shematic symbols...... when you save the project and upload it somewhere - zip it inside Kicad with "Projektdaten archivieren" - dont know the french word for it. -please overwork also your BP like/or simular like i did.... @Fader 1/2.... please open this file: Fad_2.zip shematic: also better use GND and VDD Nets.... more oversight! if you dont use a Pin off your IDC-Header (P5), then "x" them out with the blue "x" on the right side off your editor.... For what are those outer Mounting holes? they are too near to the Faders...make the pcb bigger so there is space for a Spacer/standoff, or use only the 4 inner mounting holes... which i think is enough.... again better 90° corners.... fill out your Shematics "Circuit-Field" right down - dont know the englisch or french word for "Plankopf" ... by the way you can design your own "Plankopf", so you dont see there thing like "KiCAD E.D.,A kicad 6.0.10......" keep out for mounting holes again... (see PB) dont make outher planes on VDD(+) ... mostly there can happen problems when mounting the thing to a panels, better use Ground-Planes... When looking on your FAders Footprint, and on the DAtasheet for the RA6020F then i am not sure iff the pinout is correct (the datasheet is bullshit...) but i guess you imported the Symbol and Footprint from mouser or something....then i guess its oky.... also use the design-rule check function (in a shematic and PCB-Editor) i did not looked in the other kicad-projects... but i guess its the same - a bit overwork needet..1 point

-

Yes, absolutely. Please PM me for details, ideally including your location so I can give you a shipping quote if interested.1 point

-

Looks very nice and neat .I didnt know you are so busy with things . (Thank you for your support). I was working a lot with max/msp and m4l too. Its a lot of fun , but it takes a lot of time as well :) . Enjoy and keep up this amazing work.1 point

-

So good and inspiring to see what you are creating! Good luck with your further progress, I‘m watching you :-)!1 point

-

@ cherry: the switch itself you can get already from eg https://www.reichelt.de/tastaturzubehoer-c8099.html?ACTION=2&GROUPID=8099&SEARCH=*&START=16&OFFSET=16&CCOUNTRY=445&LANGUAGE=de&r=1&SID=967792150a00d890464504461a66ae529d97182e528c945af4544 caps: amazon, alibaba,.maybe.some thing like that: https://www.amazon.com/dp/B00FYO8EDC/ref=mp_s_a_1_5?keywords=flat%2Bkeycaps&qid=1675511770&sr=8-5&th=1&psc=1 https://www.cherrymx.de/en/dev.html the low profile is maybe interesting....1 point

-

this will take a while - look into the forum in 5 weeks or so. i need the PCB to make a new version off Triggermatrix (http://wiki.midibox.org/doku.php?id=triggermatrix4) the Frontpanel is not a generic MatrixController thing - it has 17 Displays, 8 Faders, some rotarys and buttons, the Software for this is not a normal Midicontroller-code (aka Midibox NG) - its my own creation a sequencer based on MIOS. - but if i not make a shematic mistake, the pcb should be usable like the orginal BLM16*16+X in other Midibox Projects.1 point

-

1 point

-

Did you adjust the bootloader for the SSD1306? See here http://ucapps.de/midibox_ng_manual_lcd.html1 point

-

1 point

-

Here's the gerbers for the MB-6582 panel set pictured in this thread... Please credit @listen202 and @Manu29 for their efforts... _MB6582_Panel_L202-Manu.zip _MB6582_Rear_L202-Manu.zip1 point

-

Notwithstanding a possible bridge day, last Friday of the month (27.05.22 / 7:30pm), online: We organize our regular Open Hardware Happy Hour (O3H) again! This month’s topic is Open Music, since Open Hardware is of course also a topic in the field of electronic music devices (and more and more on the rise). Among other things, we will present the sample sequencer by SucoFunk, The beatmakers’s sketchbook, an Open Hardware device that was also featured at this year’s Superbooth. We have asked for other speakers, so be prepared to be surprised, and bring your own (music) projects! Presenters will include Marc Berendes, Berlin-based Open Hardware developer at SucoFunk. Marc Berendes: The beatmakers’s sketchbook – An open sample sequencer for beats on-the-go (https://sucofunk.com/) (tba) Language of the presentations will probably be German this time. Link Call: https://bbb.cyber4edu.org/b/dan-gi4-bxg-p1v Blog: https://hardware.prototypefund.de/o3h-meetup-zu-open-music/1 point

-

i guess not the pyboard uses a 12Mhz external crystal? and Mios32 needs? look at the Pinout: http://wiki.midibox.org/lib/exe/fetch.php?media=antichambre:pinout_compare_chart2.png a quick look at for example the SD-Card Pins - of the pyboard and on Dipcore or Discovery stm32F407VG - says that the use other GPIO to do things... So yes you may flash that pyboard, but the Mhz might not be right (aka need to replace the oscillator) So yes you might run MIOS afterwards... but you cant use for example the onboard SD-Card - because it is wired to other pins... you have to DO the work that antichambre did (change the GPIO ports in MIOS, make a new toolchain, and that is a Job for someone who knows what he does - i would be very happy if i could do that - or someone introduce that skill to me- but i dont have any glue about that)1 point

-

Oh si il est polyphonique ! Tu as 8 voies simultanées que tu peux router vers un canal/port midi dédié ! - Yes it it polyphonic, you have 8 simultaneous voices you can route on a dedicated midi channel/port !1 point

-

1 point

-

1 point

-

Hi ssp, Two things: First, you need to change the id of the second controller: # Bank 1 EVENT_AINSER id=1 hw_id =1 bank=1 fwd_to_lcd=1 type=CC chn=1 cc=16 range=0:127 offset=0 lcd_pos=2:1:1 label="FDR1 #%3i %3d@(2:1:2)%B" #Bank 2 EVENT_AINSER id=1001 hw_id =1 bank=2 fwd_to_lcd=1 type=CC chn=1 cc=17 range=0:127 offset=0 lcd_pos=2:1:1 label="FDR2 #%3i %3d@(2:1:2)%B" Otherwise, Midibox might get confused, all EVENT_xxx must have a unique id. Unless they are of different types. for example you can have EVENT_LED id=1 and EVENT_AINSER id=1 Second: To light an led for each bank you need the button that sets the bank to forward info to the respective LED. for example: # select Bank1 directly EVENT_BUTTON id=1 fwd_id= LED:1 type=Meta meta=SetBank button_mode=OnOnly range=1:1 # select Bank2 directly EVENT_BUTTON id=2 fwd_id= LED:2 type=Meta meta=SetBank button_mode=OnOnly range=2:2 #LEDS EVENTS EVENT_LED id= 1 range= 1:1 radio_group= 1 EVENT_LED id= 2 range= 2:2 radio_group=1 The radio group makes sure only one LED turns on I also put the switches in the same radio_group on my config, but i'm not certain it's mandatory. now, i didn't use cycle_bank, inc_bank or dec_bank but you can take a look at those examples config to see if you find something interesting: https://github.com/midibox/mios32/tree/master/apps/controllers/midibox_ng_v1/cfg/tests And also, i found usefull to add #initialize all banks to 1 log "call bank 1 for all parameters" set ^bank 1 to the section 0 of my .ngr script. this ensure that all parameters are set to bank 1 at startup.1 point

-

Aah, quite the variety of modules. The first one is a GM5 USB to MIDI Interface. This board only has 1 pair of MIDI in/out, the jumper can be used to connect a further 4 MIDO io pairs. Then we have a pair of LPCxpresso boards for the 1st gen LPC1769 STM32 microcontroller. This is a variant of MBcore 32. You dock these to a baseboard and voilà. Then we have a Microchip dev board that’s not normally a part of the MIDIbox ecosystem. Followed by a Pic18F452 MBcore8 for older projects like MBsid, MBfm and the like. Last is an AoutNG - an 8-Channel 12-bit DAC board for analog outputs. This is mainly used for the generation of up to 8 CVs at 1V/oct. These can be unipolar or bipolar. Other scales are available in the MIDIbox software. These can drive analog VCOs, VCFs and such.1 point

-

@Hawkeye Thank you for the thoughtful replies. It is easy to think of future wishes and add ons but at the same time forget about how it would effect everything else. I love the Seq4+, very little I would change! And the fact that I can get into the code and try things myself is pretty amazing. That alone is a "feature" that very few seq's can boast. @flyweightIf I was looking for more humanized recordings I'd use the longer tracks with higher divisions OR the humanizer feature! Also, you can specify your own shuffle parameters, you may find something that gives you YOUR feel.. if you could analyze how your beats groove, you may just be able to create that groove as a template and there ya go. May be worth digging into. At the same time, your experience and learning from building the Seq is not lost if you sell it. You lost time, yes. I'm sure if you put it on the market it will sell pretty quickly. ~Steve1 point

-

Quick heads up on this for anyone that might wanna do this. I had some trouble compiling the above version for Linux Mint 19.3. Couple things you might need to do: ./configure --without-residfp This was giving me a weird "you need to be on a 32-bit platform at least" error (I'm on 64-bit, Ryzen) but we don't need this for outputting to an MBSID anyway The makefiles do not add -pthread. There's probably a more elegant way to fix this, but I just edited src/Makefile and added `-pthread` to the end of CFLAGS, CXXFLAGS and that seemed to avoid the errors You may need to symlink /usr/local/lib64/vice to /usr/local/lib if installing system wide (otherwise stuff like keyboard input doesn't work) You need the ROMs of course! Doing all this allowed me to bust out the HVSC intros included in the collection. Seems to work like a champ!1 point

-

Good. Maybe someone need good midi samples for beatmaking www.lucidsamples.com/edm-samples-packs/278-edm-magical-midis-vol-3.html and https://www.loopmasters.com/search?q=midi1 point

-

1 point

-

1 point

-

for those who don't find a sd card socket for the core stm32F4. you could use micro SD card and the ADAPTATOR will be the socket like:http://www.ucapps.de/mbhp_sdcard.html first solder unused component legs to the adaptator: solder to the core but leave some space to the board for avoid short (be carefull pinning): you could fix it (glue) if you want (not done for me legs are sufficiant) et voila!1 point