Leaderboard

Popular Content

Showing content with the highest reputation since 10/02/2022 in all areas

-

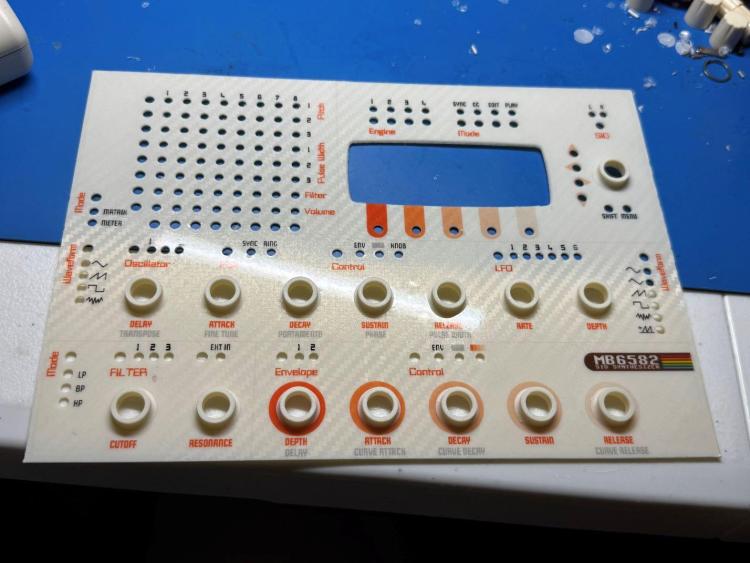

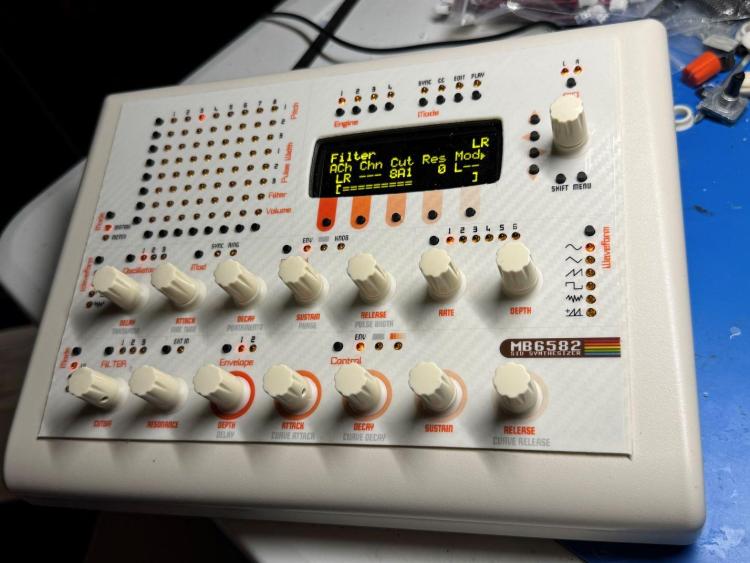

Hey everyone, just wanted to share my latest build since I'm sure there are some 3D printing enthusiasts here like myself. I bought the parts for an MB6582 about 5 years ago, if you remember Meeblip was selling those 8580 SID chips and I picked up 8 of them, and then put everything into a box in a closet . 3D printing has come a very long way since the original MB6582 was created by Wilba. I read that the JB Weld solution may or may not be holding up great after all this time. Also, I wanted to use a Newhaven OLED which is much thinner than the original LCD. I thought there must be a solution to lower the gap distance so why not create some type of spacer for between the front panel and the PCB? I designed all parts in Fusion360. The PCB screws directly into the spacer using M2.5 nuts/screws and plastic screws. The top of it has a flange that rests in the panel groove for the PT-10. Total spacer height is 5.7mm which is the height of the base of the encoders. The front panel is another 1.25mm. Everything is printed out of ASA, which is very strong and heat resistant. I designed the panel graphics in Inkscape and printed on translucent vinyl. I used Davies knobs with small printed skirts to cover up the threads of the encoders since they were exposed. I do not have a vinyl autocutter but I do have an exacto and lots of patience Overall tried going with a 80s beige computer look. A build plate for my printer created the carbon fiber effect on the panel. I'm happy to share the 3D files if anyone could use them.3 points

-

Hey man. It's actually an FR4-Standard PCB. Non aluminium. But seems pretty robust anyway.2 points

-

2 points

-

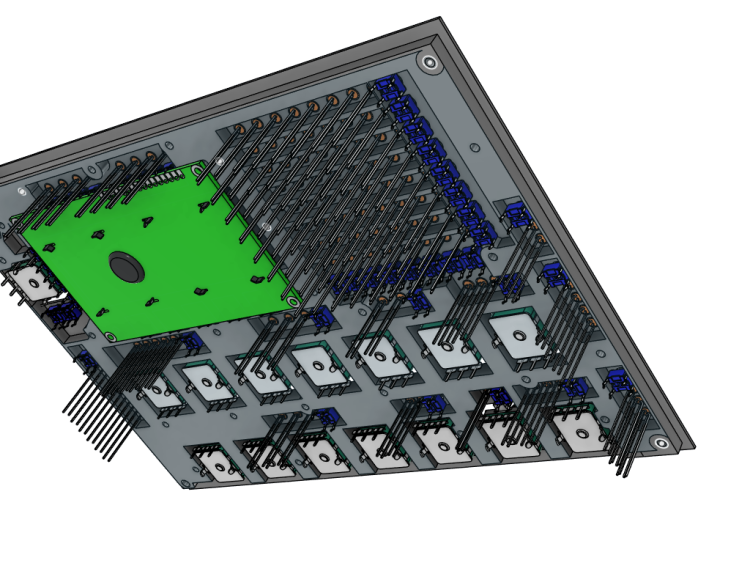

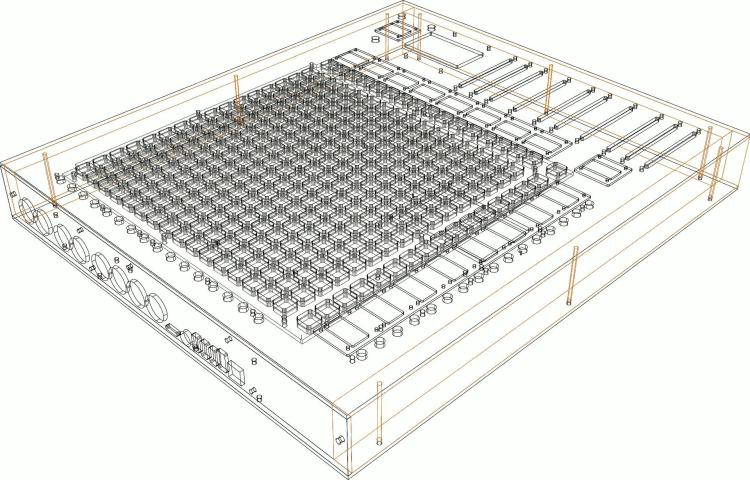

Hello everyone! Over the past few months, I’ve engineered a brand-new MB6582-style synthesizer, deeply inspired by the original Midibox MB6582 but redesigned completely from scratch for improved reliability, easier assembly, and modern component availability. Key new features: Premium ENIG front panel PCB - durable, professional finish 4 PIC cores onboard - full MB6582-compatible architecture Factory-manufactured PCB set, including the front panel Supports ArmSID, Kung Fu SID, or original 6581/6582/8580 chips Clean internal layout, solid build, and high-quality components Prices: Base unit: 420 EUR + shipping With Kung Fu SID set: 499 EUR ArmSID pricing available upon request. Availability: The license allows producing 10 units, so I’m offering 9 units for sale. 1 unit is in stock right now Additional units can be assembled in 3-4 weeks If I receive permission to sell more broadly, I plan to lower the price and release all design files as open source I will make a separate thread in Latest News or somewhere else Photos PCBs and components:1 point

-

From the album: S.M.A.K.

MBSID-6582 NES gray colour scheme with flat headed yellow LEDs and Caps from Elektron. Pac-Tec 10 Case1 point -

Thanks for keeping this projects alive I will try to buy one of them next month if its possible again thanks so much for your work Best regards1 point

-

Hello how much will cost the mb6582? and also If you plan to build a sammichFM let me know1 point

-

1 point

-

From what I gather from the manual and changelog, this LED indicates whether you have selected a „positive values only“ waveform for the LFO (instead of applying the default workaround by showing waveform LED + Random LED). It does not indicate that the value of the LFO is currently positive.1 point

-

1 point

-

To use Studio on newer Ubuntu Desktops you need to install the old libwebkit2gtk-4.0.so.37. To do so create a sources.list file for apt containing the following line: deb http://gb.archive.ubuntu.com/ubuntu jammy main And install the lib. sudo apt update sudo apt install libwebkit2gtk-4.0-dev After this delete the sources.list file. More infos on https://www.weigu.lu/music/midibox_hp_2x2/index.html1 point

-

Reflowed the ttasnsistors on the top side and now I am back to 12 LEDs on. I'm assuming the LEDs shouldn't be on, but otherwise that feels like an improvement as it means I get mattias switch events for 12 of 16. I'm also getting events for depresses on the right 4 encoders although they seem a bit random in the actual event details. I've also replaced IC2, IC3 and T3 based on advice from ChatGPT but that made no difference.1 point

-

Thanks, perhaps I'll shoot over to the UK ;-) I've rebuilt the core board now and I'm back where roughly where I started. At least I feel confident I have eliminated the core as a possible cause; the problem must be with my LeMec board. Done some more reflowing on that board and now: - just 4 LEDs light up on power up now - all encoders generate counts when rotated but not depresses - botton left 4 buttons generate no events; bottom right four are working - mattias switches generate events for the four that have illuminated LEDs but not the rest1 point

-

Cool solution, looks great! The skirts for the knobs are a nice touch. One thing I wonder about is if heat would build up here, as the free air space in the case is less and the panel is also an insulator. The SIDs are on another PCB of course.1 point

-

With velocity bars there is more info displayed and the spacing is more uniform. The hyphen/minus as a spacer for natural notes helps to connect them; with spaces it is more confusing. Do you really use those low octaves so often @anonyme-x22? If it bothers you, a workaround is to transpose either on the SEQ or your synth.1 point

-

Hello, When i mute part, i can do it by bottom row (normal known behavior), but also the top row. So it's confusing. Being able to mute only on bottom row will make the workflow more consistant. Or it could also being interesting to be able to mute differently between upper and bottom row. Like top row track 1-16 mute. Bottom row group 1-4 mute. Thanks in advance, Have a good day, Rgds,1 point

-

MB-6582 SOLD Selling these as I no longer use them. I assembled the MB-6582 myself. It has 6x 8580 SIDs installed, and could use some TLC: - The encoders occasionally skip counts when adjusting them. I think this is just down to a bad batch so replacing them should fix it - Some of the standoffs that attach the front panel to the CS PCB have come unstuck and need to be reglued The SEQ V4 works perfectly €500 for either unit I am based in Spain1 point

-

Arrived and kicking. Thank u for your service ❤️1 point

-

Confirmed over here, no humanizer being applied to CC’s. I tried with an empty track sending layer A as CC on buss 1, and another track listing to buss 1. The listening track was responding to the cc’s, but humanizer did not effect the CC’s. Then moved the cc to layer B (usually the velocity layer) and still no changing of CC’s sent. steve1 point

-

1 point

-

1 point

-

Thanks for the tpd-test app it really helped me along with this build!.1 point

-

i made a passive design, since the fan which came from mouser, was dead from the beginning... since it is a 6582, it was not going very hot anyway... but i drilled Holes into the pcb under the SID-Sockets, and cut aways some plastic from the socket too. i too drilled some holes in the plastic body under the Main-PCB too, the backside off the SID should be enough to get rid off the hot air...1 point

-

1 point

-

1 point

-

1 point

-

Thank's for the tip! What I'm looking for is either the fpd file which fits the Heidenreich case or maybe a ready made panel. The fpd file I found in the Wiki seems to be not specifically made for the Heidenreich case. I prever a fpd file which is proven to fit into the Heidenreich case before trying to adapt Wilbas files to the case.1 point

-

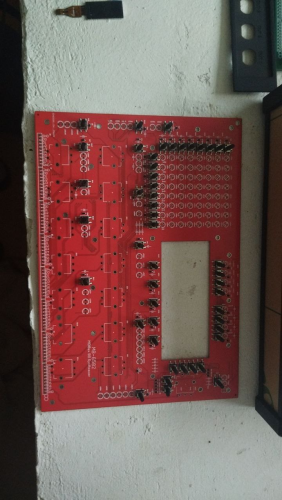

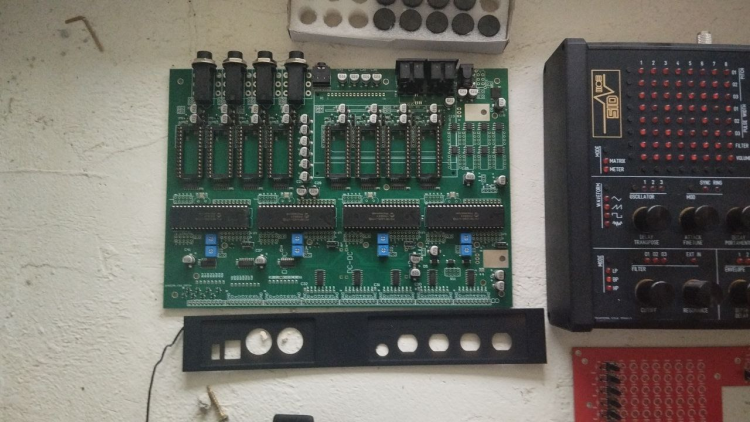

To prove that I have some PCBs here are the images of assembled sammichSIDs and sammichFM, and image of PCB of MB6582. Ideally, I would like to run a 10 pcs batch of MB6582 and for example donate 25% of revenue to Midibox project and to authors. If community and authors will approve it - I can make it. I made sammichSIDs so MB6582 would be better and more interesting. I'm just still curious if it is possible to buy originally expected enclosure. I think it is better to construct a new one using acrylic materials and probably just a PCB with a drawing for a front panel.1 point

-

Hi ssp, I don't remember if labels can be called from a map, but i don't think so. However, i think it is possible to change the display using a .ngr script. Bests Thomas1 point

-

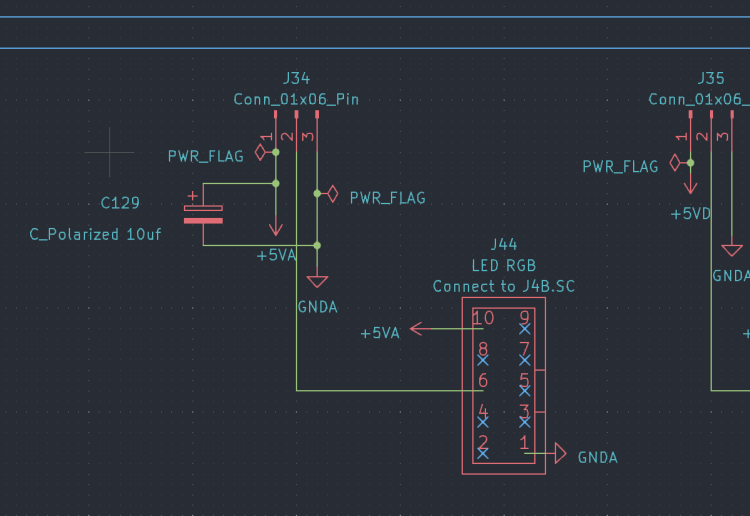

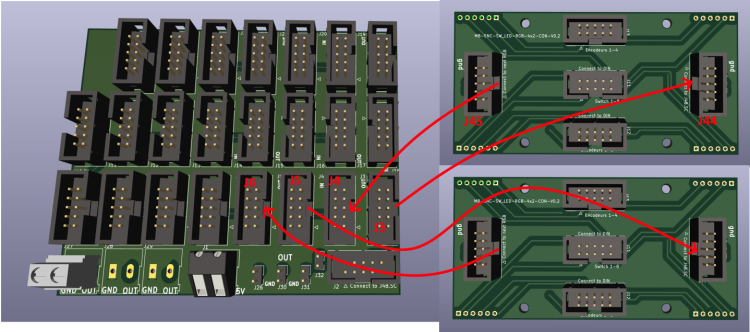

Hello, first of all thank you for your previous answers. I haven't fixed the problem with the pads yet. I'm focusing on another problem for now: with the LED rings. with 16 led ring of 16 led no problem. when I add more, the LEDs flicker. https://youtu.be/HyLkVeFtALw?si=gT09lbCxEwLRmHt8 I read here: http://midibox.org/forums/topic/21095-lre-4x1-breakable-rgb-led-ringrotary-encoder-pcb-bulk-order/?do=findComment&comment=184155 FantomXR had flickering problems, solved with a 10uf capacitor. Should I add a 10uf capacitor at the input of my LED ring cards? (as in the image below) (C129) To understand my configuration see the pdfs: LEDRING: https://drive.google.com/file/d/1XpDQBUE42IqXpXicO--B2gfIoNQDh5ga/view?usp=drive_link “power card”: https://drive.google.com/file/d/1NJ-H-QXD-tl9rU6nbYdEh2Q4jFqjWt6b/view?usp=drive_link I made a PCB that I call a “power card” that I supply with 5v 10 amps. The J2 connector of the "power card" is connected to J4b of core 32. Connector J44 of the first OLED card is connected to J3 of the “power card” Connector J45 of the first OLED card is connected to J4 of the “power card” Connector J44 of the second OLED card is connected to J5 of the “power card” Connector J45 of the second OLED card is connected to J6 of the “power card” etc.. Thank you1 point

-

Hi all , Was wondering about opening a KiCAD Section in the wiki? For tutorials , midibox libs etc... where should i put it? regards, JK Edit : A Frontpanel designer section could be useful too ?That's a soft that i think most of us use? Maybe create a "Softwares" Section?1 point

-

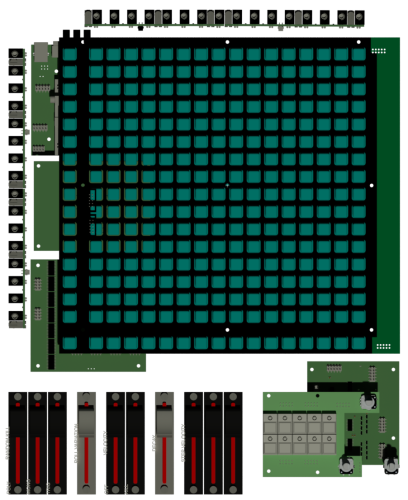

the next generation off Triggermatrix, with insights to shematic, the board-files i will not set free... the Pictures from the Boards are for debugging reasons only. where possible, i made pick and place ready boards - to reduce soldering time... at this point the big BLM16x16 board is not pick and place ready. WIKI: Triggermatrix 5 Display-Driver-SMD BLM16x16-V2 Core 4 Discovery Core 4 Disc - Midi Expansion TM5-codeblock TM5 Din Dout Gates TM5 Gate - Breakoutboards TM5 Gate - In TM5-Housing1 point

-

1 point

-

the ssd1306 oleds i received where 5V tolerant... the ws2812b is also in a range from 3.3-5.3V, dout modules also needs 5V... so your reichelt psu should do the job, and you could power them directly from the psu... but i guess you power them with the ribbon cables from your core... i dont know what Core you will use? if you use the WCORE from midiphy, then you may ran into some problems when using a external 5V PSU, see this topic: https://forum.midiphy.com/d/151-wcore-non-usb-powerd-but-still-use-as-usb-device/5 also if you are unlucky you will get walking lines on your SSD1306 screens... then it best it would to buffer each D0 D1 Clock... Pins, which are done for example in this module: http://wiki.midibox.org/doku.php?id=displaydriver-smd a plus is then you can then use more then 8 screens!1 point

-

maybe by removing the pull-Hi resistor off the HC165 Circuit, and using a Inverter on its inputs for example: https://www.mouser.at/ProductDetail/Nexperia/74HCT1G14GW-Q100H?qs=SKY61BOKKY4Uv%2FaFLc8SsQ%3D%3D https://www.mouser.at/datasheet/2/916/74HC_HCT1G14_Q100-2937184.pdf (just a example maybe there are better parts for this porpuse, and i dont know how hard to solder this one is) that would reverse Lo and Hi, and you could use this bloddy 3 LEDs ( where i think thats not a good idea, the Encoder is expensive - and not really a standard part...) but for that quick idea i would prototype that first (order a inverter, order a Encoder, make wires without pcb) ... specially iff any pull hi or pull low resistors are needet elsewhere, i guess you need a 10K pull-low resistor (to ground) on pin 3 off your Encoder then: HC165 > Inverter > Pull-Low + Pin3 since i have not much time these times, and you have plenty off modules what module i should check next? i just had a look on your 4x2 Enc RGB SW Led ring Rgb render here... and i am not 100% sure that the inbuilt RGB LEDs that enlighten the Encodersshaft dont shine on the LED-Ring and make them hard too read (maybe need some lightshielding)... by the way hard too read, those Alps Knobs are a bit big for that small Ledring - can you still see the LEDs when looking from a angle that is not 100% from top?1 point

-

That's absolutely glorious Peter! Nice work (as always!)1 point

-

You can leave off the USB, it's only an additional +5V power option selectable by jumper..1 point

-

@Hawkeye I have never seen those tutorials before! don't know how I missed that, there is a wealth of info there. Following the tutorial the transpose works, under the scheme laid out in the tutorial. I will try the Root method next and report back. Thanks!1 point

-

Yes you usually need a metallized knob to make the touch detection usable !!!1 point

-

Looks very nice and neat .I didnt know you are so busy with things . (Thank you for your support). I was working a lot with max/msp and m4l too. Its a lot of fun , but it takes a lot of time as well :) . Enjoy and keep up this amazing work.1 point

-

So good and inspiring to see what you are creating! Good luck with your further progress, I‘m watching you :-)!1 point

-

@ cherry: the switch itself you can get already from eg https://www.reichelt.de/tastaturzubehoer-c8099.html?ACTION=2&GROUPID=8099&SEARCH=*&START=16&OFFSET=16&CCOUNTRY=445&LANGUAGE=de&r=1&SID=967792150a00d890464504461a66ae529d97182e528c945af4544 caps: amazon, alibaba,.maybe.some thing like that: https://www.amazon.com/dp/B00FYO8EDC/ref=mp_s_a_1_5?keywords=flat%2Bkeycaps&qid=1675511770&sr=8-5&th=1&psc=1 https://www.cherrymx.de/en/dev.html the low profile is maybe interesting....1 point

-

control hardware yes, if it is well documentadet on the wiki (shematic, board screenshot) I too work with kicad since decades... and very sucessfull now with my actual projects - i was wondering but i planed it in kicad, and most off the boards where working 100% out off the Box (pick and place JLCPCB), ok i had a design fault on one, but that was solved with a wire-done. actual projects http://wiki.midibox.org/doku.php?id=triggermatrix5 http://wiki.midibox.org/doku.php?id=daw-ableton http://wiki.midibox.org/doku.php?id=openpad software: cant help, write my own Mios-based code, havent look into MidiboxNG - since it is a script, for me more easy to write it directly in C, (need to understand all, else i understand/learn nothing...) - so no help from this side had good expierences with jlcpcb... also with the Pick and Place service FrontPanels: maybe cheap CNC-Laser-Cutting from pcbway? https://www.pcbway.com/rapid-prototyping/CNC-machining/CNC-Laser-Cutting-Services.html suggestions? Maybe use Eurorackformat, so it can be used outside of your box too? suggestion, where usefull (wo sinnvoll) use J89 Serial Chain directly onboard (like encoder with ledring boards) to reduce wireing - a simple button board dont needs that of course.... *** if you go the Serial Chain way, then buffer the Serial chain on each module to keep the digital Signal Quality intact (very necessery) *** buffer: search for SN74LVC1G17DBVR in this shematic: http://wiki.midibox.org/lib/exe/fetch.php?media=phatline:blm16x16-shematic.pdf maybe use pick and place ready smd technologoy like i did: that makes it smaller, and less to solder, less to debug, the plastic packages stays in china, more economical special when ordering more pcbs, by that of course a module should fit all the boxes (a exotic 1 man needs it module 10times fabricated is 9 too much...) i think i dont have to say, that you should choose "Basic" Parts, and not "extendet parts" on JLCPCB, - off course on most modules you have at least one or two extendeet parts... but for example a DINX4 or DOUTX4 can be made with basic parts only... but when you also want to pick and place all the pin headers - these are extendet parts, how ever ... you may look on my last modules a bit http://wiki.midibox.org/doku.php?id=tm5-dindoutgate http://wiki.midibox.org/doku.php?id=doutx2dinx1 if you use long cables to your Displays + u use more displays then one - on the modules, use a display driver (no more walking lines) http://wiki.midibox.org/doku.php?id=displaydriver-smd what else? if you make ground or other PCB-Planes, then setup kicad that it make 1-2mm space arround solderpoints - else the Soldering Man could make shorts, or electrocemical oxidations or solder flux-low-residance could make there some problems (after years), special when the Solderstop-Pain is scratched a bit... ... and so on... PS i hate this wooble feeling off this LeMec Buttons (the last board you posted) - these Buttons are not good (for my taste) I love to work with this ones: https://www.reichelt.de/at/de/eingabetaster-schaltspannung-24v-fuer-led-sw-dtl-2-sw-p7248.html?&trstct=pos_0&nbc=1 they are expensive, but they last decades (in use, and also if you order 300 off them and let them lye arround, after 15 years they still work) They have good CLICK, like a mechanical Keyboard. your leMec Buttons are like a mixture off Rubberdome and "i have to touch this buttons into one direction X=0 Y=0 else it want switch" or you could use: https://www.midiphy.com/en/shop-details/140/4/5pcs-matias-quiet-click-tactile-switch- they are cheap but big... (aka take away a lot of Frontpanel space) or maybe you use cherry switches or simulars.... they are all 1000% better then this leMecs... ( you notice i hate them)1 point

-

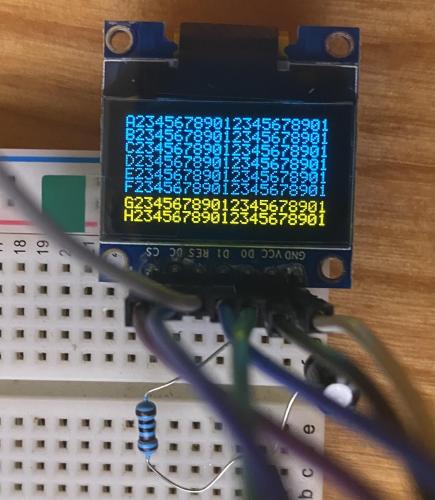

Oh, wow, I totally missed that! Thank you!!! I wasted an entire day rummaging around and didn't manage to see that :) Just in case others run across this: You want 4SPI configuration, not IIC like I have in the pic. The number of screens you have must match the configuration you set in the bootloader, otherwise you get noise, and won't be able to write to all the lines/columns Also easy to miss, but for the 1306 RES connection, you need to wire it up like this (again, connections on your 1306 PCB): GND -> 10uf cap -> 1k resistor -> VCC. Once done, RES will be tied to where the cap and resistor meet (like this) It wasn't clear to me how to actually use the bootloader for the STMF4 board, but it's essentially: Plugin your board as you normally do Open MIOS Studio Click Browse and choose the mios32_bootloader app (download here) Click Start. If it won't complete, try unpluging/pluging the board and trying again Unplug/plugin the board In the MIDI IN and MIDI OUT sections whatever app you had prior to all of this might be listed, but it doesn't actually exist (and it shouldn't). That's why you now see the error "No response...". The new app, MIOS32, took its place and you need to refresh to see it. Click Application -> Rescan MIDI Devices Click Understood in the pop-up (this will make your old app disappear, and the MIOS32 app show up) Change MIDI IN and MIDI OUT to MIOS32 Enter these one by one into the input box: (send a command to MIOS32 application). Keep in mind lcd_num_x must match the number you have chained: set lcd_type GLCD_SSD1306 set lcd_num_x 1 set lcd_num_y 1 set lcd_width 128 set lcd_height 64 store Yah. Bootloader is done. Time to restore your app in MIOS Studio: Click Browse and choose whatever app you want, like midibox_ng Click Start. Like the bootloader, if it won't complete, try unpluging/pluging the board and trying again Unplug/plugin the board Now for some test display data. Lets set some values for your SSD1306 OLED's in MIOS Studio: Click on Tools -> MIOS32 File Browser Click Create File Create some name like LCD.NGC Click Update Click on the file you just created Click Edit Text and add the following test example: RESET_HW LCD "%C" LCD "@(1:1:1)A23456789012345678901234567890" LCD "@(1:1:2)B23456789012345678901234567890" LCD "@(1:1:3)C23456789012345678901234567890" LCD "@(1:1:4)D23456789012345678901234567890" LCD "@(1:1:5)E23456789012345678901234567890" LCD "@(1:1:6)F23456789012345678901234567890" LCD "@(1:1:7)G23456789012345678901234567890" LCD "@(1:1:8)H23456789012345678901234567890" Click Save You should now have 8 rows and 21 columns of text. If you need to flip it 180 degrees, you can redo the steps above and add set lcd_type GLCD_SSD1306_ROTATED before you store.1 point

-

Hi Therezin, I mounted the monitor upside-down because of the viewing angle. This specific monitor has been designed to be looked at from above. It's actually pretty good from around 10° to 90°, but from 95° to 180°, the visibility is very bad. Therefore i had to reverse it so when i seat behind my desk, i'm in the good range. Let me know if this explanation is not clear enough, it's pretty hard to describe in a foreign language. Thomas1 point

-

Hi everyone! Quick update here. I finally finished my controller and installed it in my small control-room. Here it is. I really like the way it turned out, i'm working with it since 2 weeks now, and it's a real bonus to the ergonomics. It still have room for improvements but that was expected and i will continue to work on it in the next future. I'd like to thank everyone on this forum who helped me build this and a BIG thanks to TK and all the midibox team. Without this place I would have never been able to even start this project. Cheers, Thomas1 point

-

@Hawkeye Thank you for the thoughtful replies. It is easy to think of future wishes and add ons but at the same time forget about how it would effect everything else. I love the Seq4+, very little I would change! And the fact that I can get into the code and try things myself is pretty amazing. That alone is a "feature" that very few seq's can boast. @flyweightIf I was looking for more humanized recordings I'd use the longer tracks with higher divisions OR the humanizer feature! Also, you can specify your own shuffle parameters, you may find something that gives you YOUR feel.. if you could analyze how your beats groove, you may just be able to create that groove as a template and there ya go. May be worth digging into. At the same time, your experience and learning from building the Seq is not lost if you sell it. You lost time, yes. I'm sure if you put it on the market it will sell pretty quickly. ~Steve1 point

-

Hi everyone ! I experienced the same problem, and The Ancient One's solution works perfectly for me. I changed the 220R resistors to 68R for R21 and R22. Now the 9090 detects the signal without any issue. Thank you a lot Michael ! Théo1 point

-

1 point